11

FIG-02. Vehicle Inspection

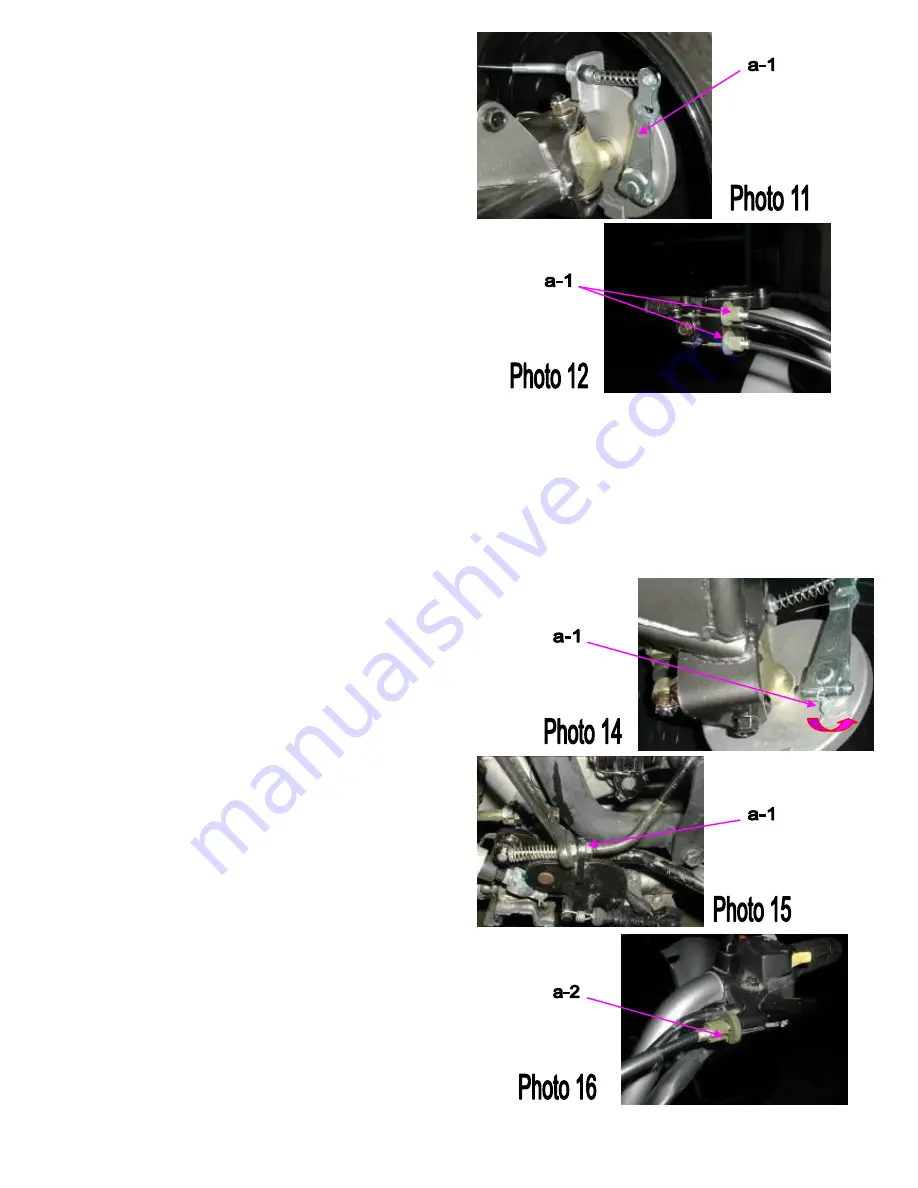

FRONT BRAKE ADJUSTMANT

The front brake has two cables to control right and

left side brake simultaneously.

You could adjust the gap of the front brake (a-1).

(Photo 11)

Loosen the fix nut (a-1) and adjust the position of cable

to proper situation.

(Photo 12)

Inspect the front brake lever and cable for excessive

play or other damage.

Replace or repair if necessary.

Measure the free play of the brake lever at the end of

the lever. The standard is 10~20 mm.

Adjust the free play of the front brake lever by turning

the adjuster on the brake lever assembly.

The brake shoe uses an arrowhead on the front brake

plate to indicate pad condition.

When the arrowhead is beyond the wear limits shown,

the brake shoes need to be changed. (a-1)

(Photo 14)

REAR BRAKE ADJUSTMENT

Install the rear brake cable fixing nut set & adjust the

brake cable.

1. Spin the gap adjuster on the left lever to the shortest

position. (a-1)

2. Adjust the adjusting screw and keep the gap within

2-3 mm. (a-2)

(Photo 15,16)

Summary of Contents for 180??

Page 1: ...Kolpin Powersports 180cc Service Manual...

Page 7: ...5...

Page 19: ...17 0 6 0 7 mm...

Page 30: ...28 FIG 10 Front Brake BRAKE SYSTEM Brake Parts Location...

Page 40: ...38 0 6 0 7 mm...

Page 69: ...67...

Page 74: ...72 0 6 0 7 mm...

Page 86: ...84 0 6 0 7 mm...

Page 87: ...85 FIG 21 MAIN WIRING DIAGRAM...