Vers. 280519

8

PIN

NAME

FUNCTION

OUTPUT

1

+24V

+24V voltage protected. The maximum current consumption is 400mA. CAN NOT BE

USED TO POWER EXTERNAL DEVICES.

2

GND

Common pin. Signals must be taken between this pin (GND) and the respective signal

pins.

3

ERROR

Error signal: it activates every time an error occurs.

The red led on the front panel will switch on.

Signal is 24V.

4

MOTOR ON

(\W)

It activates when the motor turns during screwing. Signal is 24V.

5

SCREW OK

Correct screw signal. The green led on the front panel will switch on.

Signal is 24V.

INPUT

6

NOT USED

Not used

7

STOP

MOTOR

Remote motor stop. If it’s activated the message “STOP MOTOR ON” appears on the

display. The motor will stop and won’t start working again as long as the contact is

closed.

8

REVERSE

Remote motor start with torque control while unscrewing.

9

START

Remote start with torque control while screwing.

10

GND

Common pin. Signals must be taken between this pin and the respective signal pins.

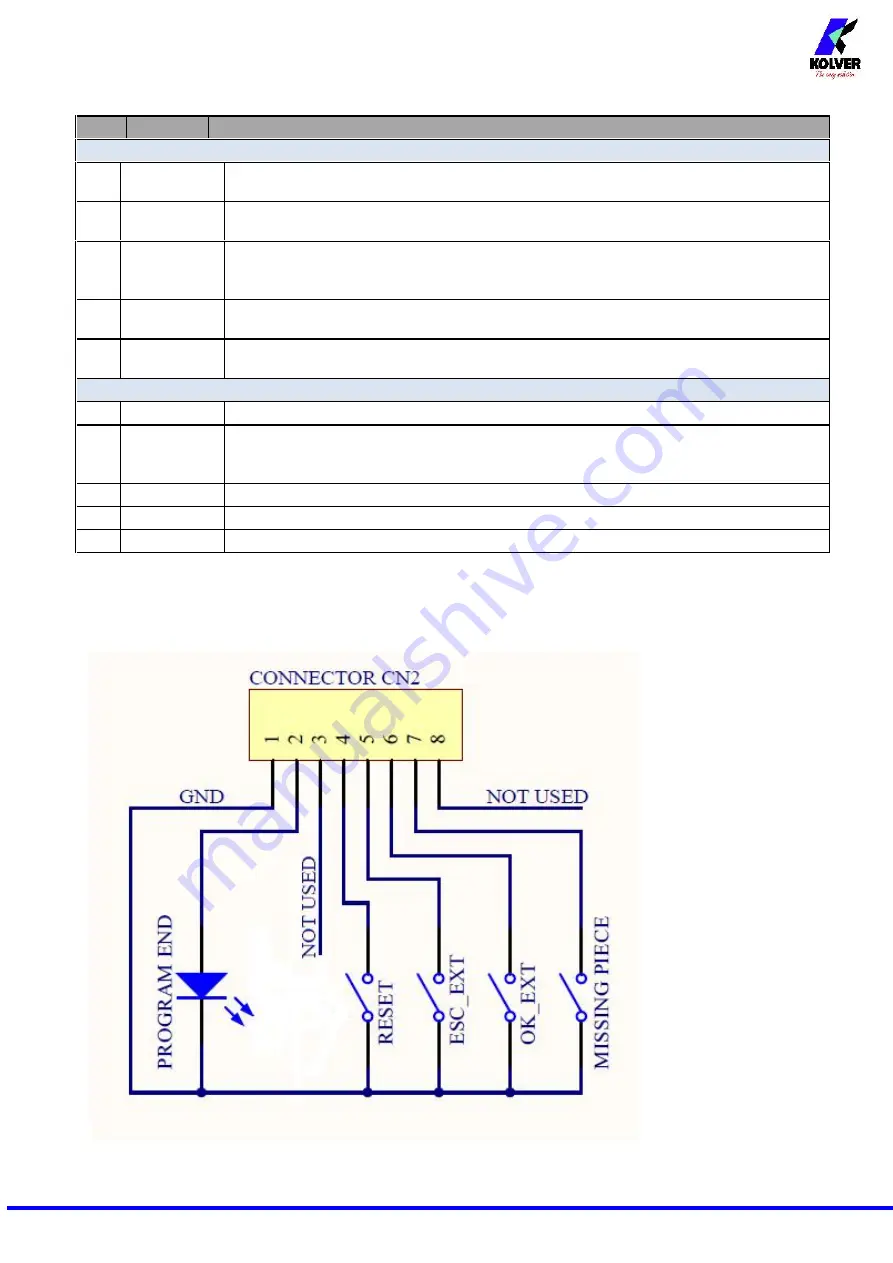

CN2 CONNECTOR

–

8 pin: