Vers. 100822 Page 8

This function overlaps other time settings (Fast Speed, ramp time, minimum time, maximum time) from the

motor start on.

ATTENTION: This function is useful for applications where the prevailing torque is higher than the final

torque (for example trilobal screws or locknuts).

Please use this function with utmost attention because an incorrect use can damage both the assembly

and the screwdriver.

Torques reached during the max torque time won’t activate the torque signal. “

Error pvt time

” will be

displayed and the red led will light up. You will hear two beep sounds, too.

18) Rotation:

You can choose between right tightening (standard screws) or left tightening (left threaded

screws). All the other functions will adapt to the selected direction of rotation.

19) Press OK:

when ON, press OK at the end of each program.

When OFF, the control unit resets automatically at the end of each program.

20) Press ESC:

when ON, press ESC to reset the control unit.

When OFF, the control unit resets automatically after an error signal.

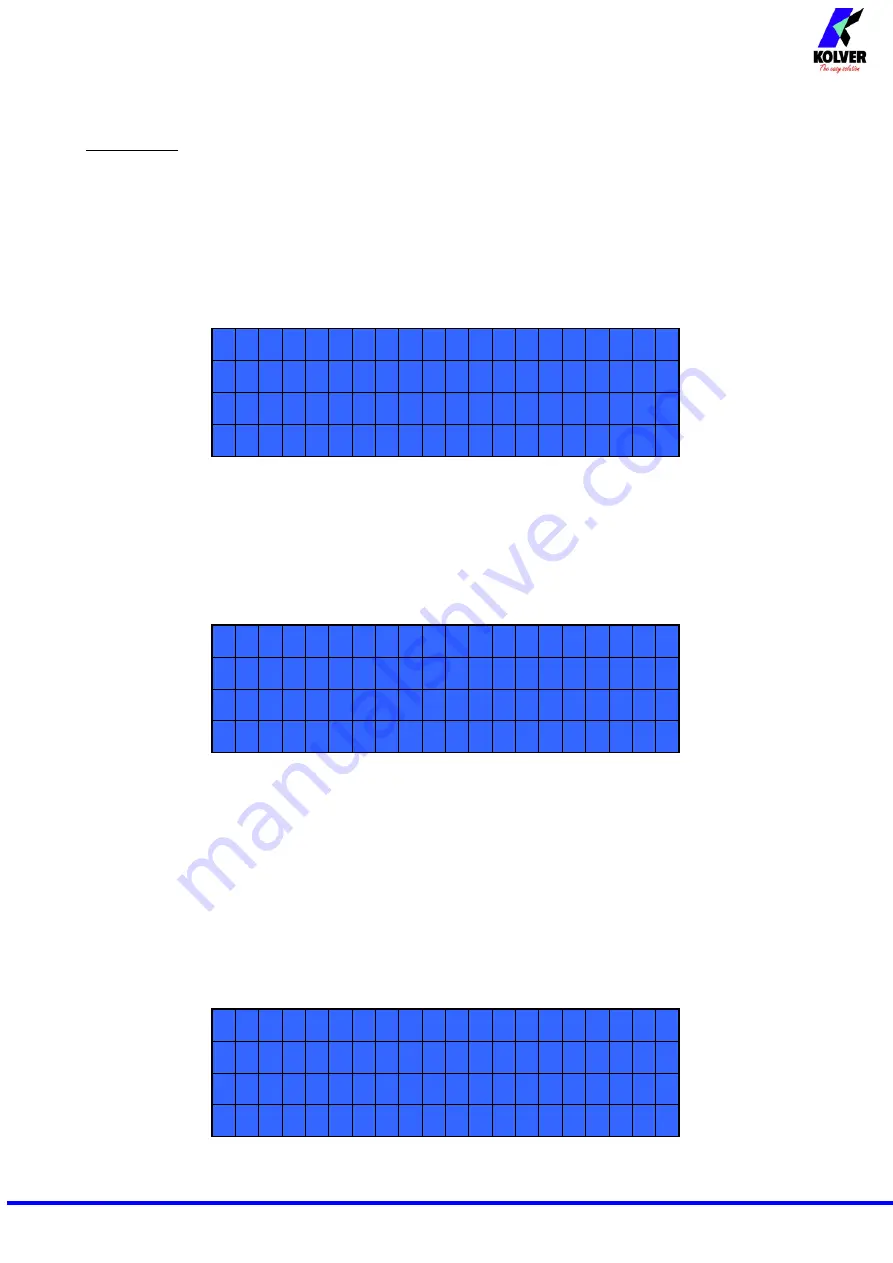

- - - - - M E N U - - P R : 1 - - - - -

2 1 ) R e s e t : o n

2 2 ) E r r o r l e v e r : o n

2 3 ) D e f i x a l l o w : o f f

21) Reset:

you can reset the program or the single screw.

22) Error lever:

when ON, an error signal will occur when the lever has released before reaching the torque.

When OFF, this function doesn’t work.

23) Defix allow:

when OFF, the reverse is NOT enabled.

24) Show Torque:

When ON, you will see the torque value (Nm or in.lbs) on the main screen.

When OFF, the torque value won’t be displayed.

(To modify the calibration parameters see paragraph Torque calibration).

- - - - - M E N U - - P R : 1 - - - - -

2 4 ) S h o w t o r q u e : o f f

2 5 ) T o r q m i n : 0 . 0 0 N m

2 6 ) T o r q m a x : 2 0 . 0 0 N m

- - - - - M E N U - - P R : 1 - - - - -

1 8 ) R o t a t i o n : r i g h t

1 9 ) P r e s s O K : o f f

2 0 ) P r e s s E S C : o f f