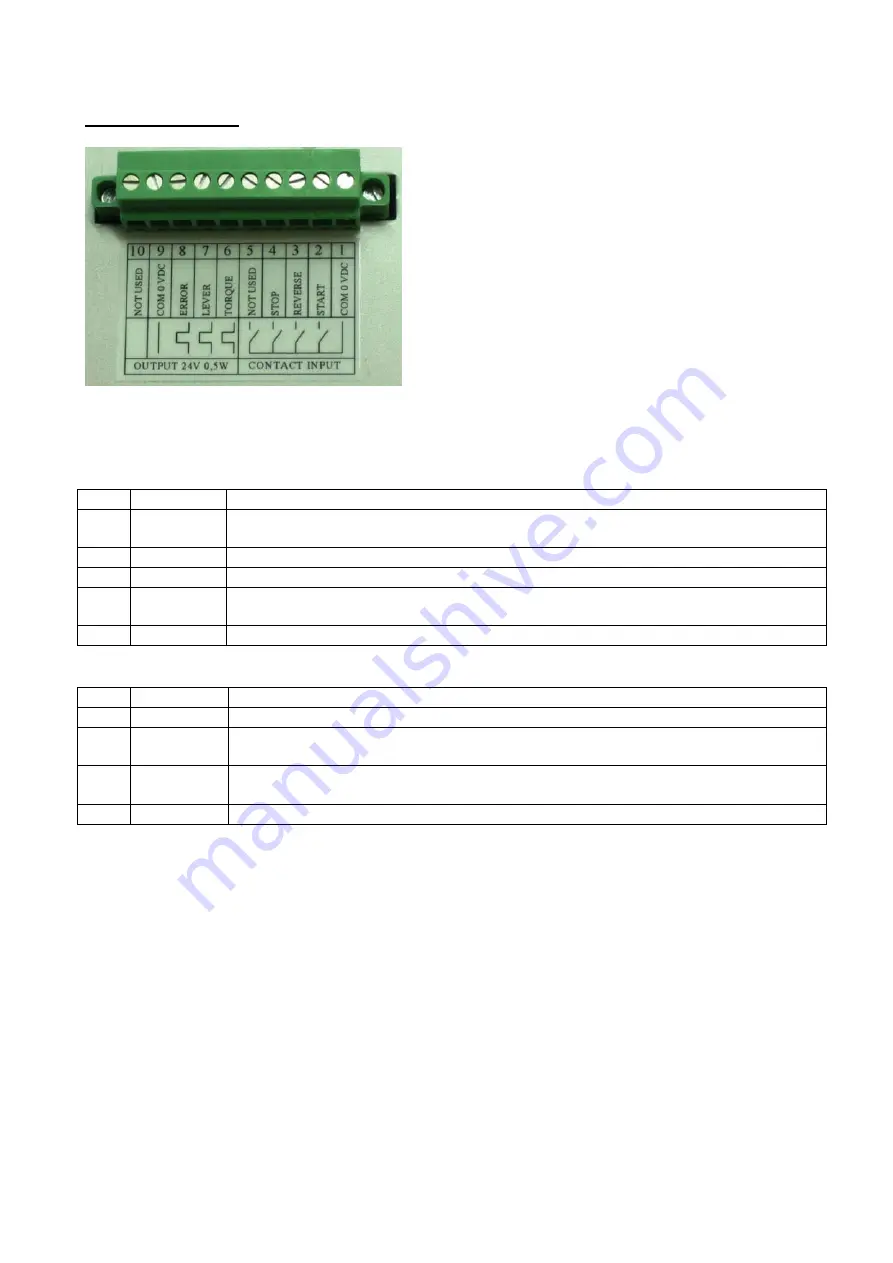

I/O CONNECTION

On the back panel you’ll find only one connector I/O 10 pins which must be connected to the 90°

connector coming from the unit.

INPUT:

PIN

FUNCTION

1

COM 0VDC Common pin. By closing the contact between pin 1 and any of the other pins ( 2, 3, 4, 5)

to start the function you need.

2

START

Remote start. Clockwise. Torque control.

3

REVERSE

Reverse remote start. Counterclockwise. No torque control

4

STOP

Stop motor. “STOP ACTIVE”screen. Motor stops and starts again after the contact has

opened.

5

NOT USED Only used in special versions.

OUTPUT:

PIN

FUNCTION

6

TORQUE

Torque reached signal. Signal is 24V 20 mA , max 0,5W.

7

LEVER

Lever signal: when lever is pressed or when the start is remote. No signal during

unscrewing cycle. It resets after their release. Signal is 24V 20 mA , max 0,5W.

9

COM0VDC Common pin for any output. Signals must take between pin 1 ( 0VDC common) and the

other pins (6,7 and 8).

10

NOT USED Only used for special versions.

Output signals are protected. Overload of

these 3 available signals (> 60 mA) or short circuit will result

in the stop of the unit. To re-activate signals, i

t is necessary switch off the unit for 5-6 seconds, check

connections outputs then switch on the unit.

BIP SOUNDS

Bip sounds at the end of the screwing allow to check if the screwing itself is correct or not.

A screwing results correct when the torque has been reached satisfying all the settings (0,5 sec bip

sound). Torque reached during Ramp or Brake Time (only on hard joint) will result 3 bip sounds.

NB

. Torque reached during Ramp or Brake Time will result in torque reached signal. For Brake

Time only in error signal also.