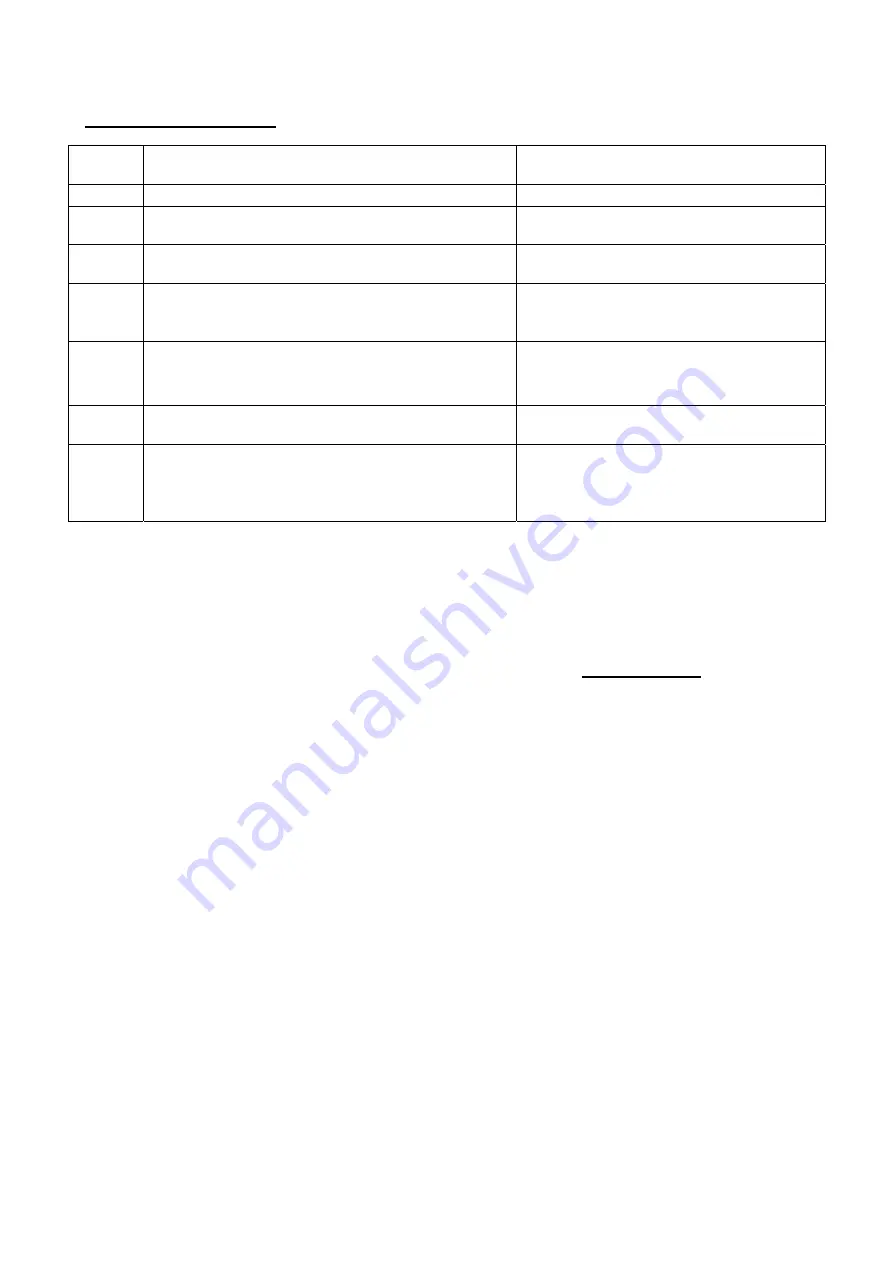

TROUBLE SHOOTING

ERROR

#

PROBLEM ACTION

/

SOLUTION

0

No connection between main PCB and display PCB

Check flat connector inside the unit

1

Choosing SOFT joint and working on a HARD joint:

the screwdriver will stop

- Switch the unit off and on again after 5

seconds and check the joints

2

Choosing HARD joint and working on a SOFT joint:

the screwdriver will stop

- Switch the unit off and on again after 5

seconds and check the joints

5

Bus undervoltage (it happens when the Vbus

to the motor remains below 25V for more than 3

seconds)

- Make sure that 110/230 (depending on

Country) VAC input is supplied

6

Overload on bridge H (it happens when current on

mosfets of bridge H > 10 A for more than 600 ms)

- Reduce cycle rate

- Avoid motor stalling

7

Motor not detected (it happens when the motor

connection is missing)

- Check cable and connection between

screwdriver and controller

8

Overload on bridge H (it happens when current on

mosfets of bridge H > 14,5 A for more than 10 ms)

- Reduce cycle rate

- Avoid motor stalling

- Unscrewing too heavy (> tool torque

range)

NB. TO RESET ERRORS, TURN OFF THEN SWITCH ON THE UNIT. RESET OF ERRORS #6

AND #8 COMES AUTOMATICALLY AFTER THE PROBLEM END.

IF THE PROBLEM PERSISTS, PLEASE CONTACT YOUR NEAREST KOLVER DEALER.

EDU1AE power supply and control unit is a maintenance free unit. Should you need any assistance please

call the nearest Kolver dealer in your Country or contact directly Kolver at

kolver@kolver.it

or call

+39 0445 371068. In the US call 978-692-2468.