FEATURES

CV THEORY

BASIC SETTINGS

Switching PSU

To make sure the RH301 runs without any problems we recommend using a 9 Volt

power supply (center negative) with a minimum of 500mA at all times. This to make

sure the sensor circuit receives enough current to operate. Before you plug in the

PSU, make sure the power supply is rated for the line voltage of your country: 120 VAC

for the USA, 220 VAC for Europe and most other countries.

How to clean your RH301

The RH301’s body is white, which means the chance of it becoming dirty after a show

or intense studio session is high. To clean the pedal, use some pure cleaning alcohol

(f.e. isopropinol). Make sure you use it safely, that stuff is pretty flammable. Also make

sure there is no solvent mixed in, this will remove the screen printing of the pedal.

We noticed by using a clean toothbrush you can cleanup the sensor! We recommend

using a soft or medium one, not too hard, so you don’t scratch the sensor surface.

I have my DAW as a master clock controlling the RH301 but the tempo is fluctuating.

What can I do?

Many sequencer programs and other music software will send all available MIDI

information on all available MIDI channels at the same time which can sometimes lead

to unstable MIDI clock information because of sound card or hardware limitations. Try

to disable unnecessary MIDI information and choose the right MIDI channel to send

your data to the RH301. This will improve the accuracy of the MIDI clock signal being

sent into the RH301.

My LFO will randomly reset while syncing to external clock signals?

Please check your MIDI/DIN Sync/analog clock connections. Many problems come

from cheap or broken cables. Also make sure that you don’t accidentally modulate

your LFO rate via a CV signal attached to LFO SPEED and keep in mind that if you do

so, the LFO needs one bar to adjust to the new tempo.

I connected my DAW to the RH301 via MIDI but the pedal doesn’t seem to start?

First make sure that you set the master clock sync source to EXT and make sure

that your DAW is sending the correct MIDI signals. The RH301 expects a MIDI clock

signal, not a MIDI time code. Further, your DAW should send a start signal whenever

you hit play. Sometimes it can happen that programs only send a start signal in the

beginning of a song, not every time when you hit Play – for example in Ableton Live

you should try to set “MIDI Clock Type” to “Pattern” in the MIDI Sync preferences tab.

Your RH301 also won’t start to sync to MIDI when there is a cable plugged into the EXT.

CLOCK jack on the patch bay – even if no clock signal is present at that input. Also,

check your MIDI cables. A large percentage of problems with MIDI sync come from

cheap or broken MIDI cables. If you have the opportunity, try different MIDI cables.

Some of my equipment is starting to hum when I attach a MIDI cable?

This can happen in some setups, mostly involving USB MIDI interfaces or other

equipment with a USB MIDI connection (sound cards, hardware MIDI controllers,

etc.). Try to prevent ground loops and check your MIDI connections – did we already

mention that a lot of problems come from cheap or broken MIDI cables?

When I connect my drum machine to the DIN OUT of the RH301 it starts and stops

randomly?

Please check the DIN cable that you use. Like with MIDI, most of the problems stem

from defective or wrong DIN cables. Make sure that all the pins on the cable are

connected from one end to the other. With some MIDI cables it can happen that only

the pins used for MIDI are actually connected through the cable. MIDI and DIN use the

same cable and plug but not the same pins on that cable.

I patch my sensor to the CV inputs and it doesn’t seem to change anything?

Make sure you use the correct PSU (9V, 500mA, center polarity negative) for the

sensor to work correctly. Have a look at the back of the pedal and check if your CV

attenuators are in the right setting. Also keep in mind that the incoming CV signal is

added to the corresponding knob on the front panel (LFO RATE and LFO SYMMETRY)

and you won’t hear your changes if they are set too high.

I set my RH301 to FREE mode / EXT. mode and sync to an external clock signal but my

DAW/synthesizer/drum machine doesn’t start playing?

The RH301 converts incoming start / stop signals from MIDI to DIN Sync. If, however,

you miss those start/stop signals because they were sent before you plugged in the

cable or none are sent at all you have to create them yourself by pressing the large

black pushbutton.

The RH301 enables you to accomplish a couple of different tasks, including convert-

ing clock signals from different formats into other formats. The RH301 can work with

and be synced to analog clocks, MIDI and the DIN Sync format.

For most applications it is necessary to achieve two things: First, sync the tempi of

two or more pieces of gear so that they are running at the same speed. The second

thing you need to achieve is to have the two synced tempi run in phase, for example

let them start running at the same time. These two steps are solved differently in the

three clock formats that the RH301 is compatible with.

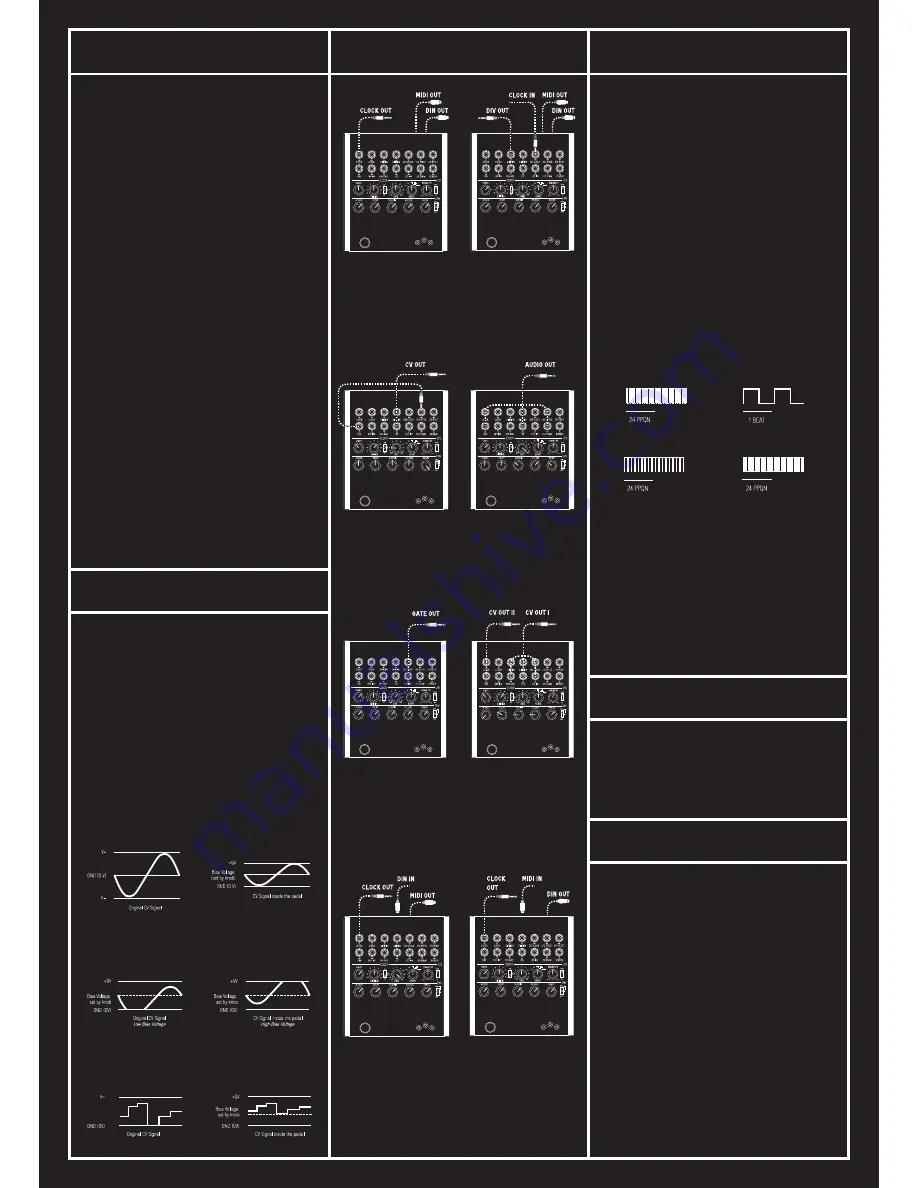

MIDI is a digital communication standard from the 80s, coming in the flavor of a serial

protocol. With MIDI clock, the clock signal itself consists of 24 pulses (called ‘ticks’)

per quarter note to sync the tempi together. For a synchronized start and stop of se-

quencers, LFOs or other functions, start and stop bytes are sent over the same cable.

When you run the RH301

in SLAVE mode, all incoming MIDI messages are merged

with the clock to the output.

DIN Sync is an even older synchronization possibility from the pre-MIDI age. It usually

uses 24 pulses (sync24 – seldom sync48, sync96 or even sync192 (you can set your

preferred DIN sync format via a jumper on the main PCB, it’s set to Syns24 by default)

per quarter to sync tempi together. For the synchronized starting and stopping of

devices, a gate signal is used. If the gate is high, it means start/run,while if it is low,

it means stop.

With analog clocks, the matter is also pretty straight forward: the clock signal con-

sists of a pulse or square wave that syncs the tempi. Starting and stopping can be

solved through various approaches, most of them include a start/stop gate. All of

the mentioned standards have been brought together in the RH301 to provide a us-

able working environment, no matter what setup you use.

The difference between MIDI, DIN Sync and Analog Clock Signals

SYNC OFF BEAT

The push button can also be used to sync “off beat”: If you push it while the RH301 is

running already the pedal will reset its internal clock to 0, in sync with the incoming

clock. This way you can manually sync the RH301 into shifted clock signals.

UPDATING FIRMWARE

The RH301 provides the possibility of updating its firmware by sending (‘dumping’)

MIDI SysEx data through a MIDI cable connected to the DIN/MIDI input on the back of

the pedal. To get into firmware update mode, unplug the power cable as well as any

other connections on the patchbay or back panel jacks. Press and hold the large

black pushbutton while re-connecting the power cable. Keep holding the button

for 2 seconds. If executed correctly, the blue light around the pushbutton should

now steadily glow blue. Connect a MIDI cable between the DIN/MIDI input on the back

panel of the RH301 and your MIDI host. The RH301 is now ready to receive firmware

updates. For more detailed information on this topic and the latest firmware please

check out the RH301 product page on www.koma-elektronik.com

The concept of control voltage (CV) is not hard to understand: Instead of turning a

knob on your pedal, you simply connect a voltage – the control voltage – to the cor-

responding CV input that does the job for you. So for example if you want to have

a quickly varying LFO SYMMETRY you don’t have to turn that knob all the time, back

and forth until your fingers fall off, but simply connect an alternating CV to the LFO

SYMMETRY input.

You can use control signals from any source to manipulate certain features of the

RH301. All of the CV inputs of the RH301 accept bipolar as well as unipolar control

voltages, but work best with CV from 0 – 5V. The incoming CV signals are mixed to-

gether with the corresponding knob on the RH301 itself and we provide you with a

attenuator for each CV input on the backside of the panel.

If you notice a significant distortion or clipping in your control signal waveform or

strange CV behavior simply turn the attenuator counter-clockwise (towards the word

‘CV’) until you hear your desired result. By turning it counter-clockwise you attenuate

the incoming CV signal. Fully counter-clockwise means that the incoming CV signal

is completely gone, whereas fully clockwise means that the incoming CV signal is

arriving to the circuit unattenuated. Furthermore you can set an offset voltage to

your control voltage to adjust the CV signal to your needs. The offset voltage is set

by the corresponding knob on the front panel (LFO RATE and LFO SYMMETRY). There’s

also a distinction between bipolar and unipolar signals. This is best explained with

a few pictures:

BIPOLAR CV SIGNALS

So, what happens? The incoming CV signal is shifted around the voltage that you

select with the corresponding knob. Example: if you insert a -5V to +5V sine wave

into the LFO SYMMETRY CV jack you will get the following results while turning the

SYMMETRY knob:

BIPOLAR CV SIGNALS

A similar thing happens to unipolar CV signals: Their point of origin (0V) is shifted by

the amount set with the corresponding knob. In other words: You add the voltage of

your knob to the voltage of your incoming unipolar CV signal.

UNIPOLAR CV SIGNALS

WARRANTY

KOMA Elektronik warrants its products to be free of defects in materials / workmanship

and conforming to specifications at the time of shipment for a period of two years

from the date of purchase. During the warranty period any defective products will be

repaired or replaced at KOMA Elektronik’s option on a return-to-factory basis. This

warranty covers defects that KOMA Elektronik determines are no fault of the user.

Returning your product?

You must obtain prior approval in the form of a RMA (Return Material Authorization)

number from KOMA Elektronik before returning any product.

Email us at support@koma-elektronik.com to request the RMA number. All products

must be packed carefully and shipped with the KOMA Elektronik supplied power

adapter. Sorry, the warranty will not be honored if the product is not properly packed.

Once you have received the RMA#, write it on the box together with the word:

WARENRUCKSENDUNG and carefully pack your product, ship the product to KOMA

Elektronik with transportation and insurance charges paid, and include your return

shipping address.

What will we do?

Once received, we will examine the product for any obvious signs of user abuse or

damage as a result of transport. If the product has been abused, damaged in transit,

or is out of warranty, we will contact you with an estimate of the repair cost. Warranty

work will be performed and KOMA Elektronik will ship and insure your product to your

address free of charge.

How to initiate your warranty?

Please initiate your warranty online by sending an email to

support@koma-elektronik.com!

TECHNICAL SPECS

Casing

Powder coated aluminum casing, silk

screened text and wooden side panels.

Dimensions

23 cm x 20 cm x 5 cm (L x W x H) /

9" x 9.8" x 2" (L x W x H)

Net. Weight

1000 gr / 2.2 lbs

Shipping Weight

1.5 kg. / 3.3 lbs including power adapter

and this instruction manual.

Power requirements

9V DC power adapter, 500mA min, center

polarity negative (only use the KOMA

adapter shipped with the pedal).

ANALOG CLOCK IN

ANALOG CLOCK OUT

MIDI

DIN SYC

S-TRIG

Some synthesizers – especially older Korg,

Moog and Yamaha ones – expect S-Triggers

on certain trigger inputs. Set the LFO to

square wave and connect the inverted LFO

output to the S-Trigger input. Set the LFO to

sync mode, turn the LFO symmetry fully CCW

to be on-beat, and turn it clockwise to add

a groovy feeling to it.

RHYTHMICALLY

CHANGING LFO PATTERN

Take a standard 1/4” patch cable and con-

nect it from the envelope output to the

LFO speed input. Set both LFO and enve-

lope generator to sync and create a slow-

ly changing envelope. The envelope will

change the LFO division in a rhythmical

manner. Pattern mayhem!

LFO ENVELOPE PING PONG

LFO Envelope Ping Pong: Take a standard

1/4” patch cable and connect it from the

inverted LFO output to the envelope gate

input (ENV GATE). Set the LFO to SYNC and

chose the square wave shape. Play around

with the LFO symmetry knob. Your envelope

will now start its cycle every time the LFO

just went low, so they are playing in a nice

ping-pong way but still in sync with the rest

of the clock signals.

LO-FI PWM OSCILLATOR

Use the LFO as an oscillator and a loop-

ing ENV into the LFO SYMM to modulate

the pulse width of the waveform. Experi-

ment with other wave shapes for different

sounds and adjust the speed to change

the pitch.

DAW AS MASTER

Set the master sync source to EXT. and plug

the MIDI cable with the clock signal into the

DIN/MIDI IN jack. A start / stop byte from the

external clock is translated into a corre-

sponding byte, received by the pedal and

sent to the DIN and MIDI OUT jacks. If there’s

no start / stop byte, the black push button

can be used to start/stop the pedal and

send out the information from the DIN and

MIDI OUT jacks.

DIN AS MASTER

Set the master sync source to EXT and plug

the DIN cable into the DIN/MIDI IN jack. An

incoming start / stop gate is translated

into a corresponding start / stop byte at

MIDI OUT. If no start / stop gate is received

by the pedal, create your own by pressing

the black push button. This starts the pedal

and sends a MIDI start / stop byte to MIDI

OUT as well as a start / stop gate to DIN OUT.

EXT CLOCK AS MASTER

Set the master sync source to EXT. and

insert a cable with a clock into the EXT.

CLOCK jack. The pedal reacts to rising edge

clock signals from 0V to at least 3V. Use

the black push button to send start / stop

bytes (MIDI) and start / stop gates (DIN) on

the next rising edge trigger. The EXT. CLOCK

input is a switching type jack that overrides

the other sync settings.

RH301 AS MASTER

For the RH301 to be the master clock

source, there are two possibilities: set the

master clock to FREE and adjust the tem-

po with the TEMPO knob. Pressing the black

push button, creates the start / stop func-

tions. Or set the master clock to TAP, then

use the black push button to tap a tempo.

After the third tap a start byte and gate is

created automatically.