OPERATION

OPERATION

3-69

OPERATION

3

CHECK BEFORE STARTING ENGINE, ADJUST

3

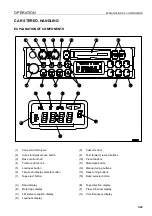

WALK-AROUND CHECK

3

Before starting the engine, look around and under the machine to check for loose nuts and bolts, or leakage of oil,

fuel, or coolant, and check condition of the work equipment and hydraulic system. Also check for loose wiring,

play, and accumulation of dust at places with high temperatures.

WARNING

q

Leakage of oil or fuel, or accumulation of flammable material around high temperature parts, such as

the engine muffler or turbocharger, may cause fire.

Check carefully, and if any abnormality is found, repair it or contact your Komatsu distributor.

q

Do not get on or off the machine from the rear. Using this position is dangerous because it is easy to

slip and you cannot be seen from the operator's compartment. Always use the handrail and step at the

side when getting on or off the machine.

If the machine is at an angle, make it level before checking.

Before starting the engine, look around the machine and under the machine to check for loose nut or bolts, or leak-

age of oil, fuel, or coolant, and check the condition of the work equipment and hydraulic system. Check also for

loose wiring, play, and collection of dust at places which reach high temperatures.

Always carry out the items in this section before starting the engine each day.

1.

Check for damage, wear, play in work equipment, cylinders, linkage, hoses.

Check that there are no cracks, excessive wear, or play in the work equipment, cylinders, linkage, or hoses. If any

abnormality is found, repair it.

2.

Remove dirt and dust from around engine, battery radiator.

Check if there is any dirt or dust accumulated around the engine or radiator. Check also if there is any flammable

material (dead leaves, twigs, grass, etc.) accumulated around the battery or high temperature engine parts, such

as the engine muffler or turbocharger. Remove all such dirt or flammable material.

3.

Check for leakage of water or oil around engine.

Check that there is no oil leakage from the engine or coolant leakage from the cooling system. If any abnormality

is found, repair it.

4.

Check for oil leakage from power train case, final drive case, hydraulic tank, hose, joint.

Check that there is no oil leakage. If any abnormality is found, repair the place where the oil is leaking.

Check for leakage of oil from the undercover. Check the ground for traces of oil leakage.

5.

Check of the undercarriage parts.

Check track shoe, sprocket, idler, guard for damage, wear, loose bolts, or leakage of oil from rollers, etc.

Repair them if any trouble is found.

If any damage, wear, or oil leakage is found, repair the problem and tighten the bolts.

Summary of Contents for 76243

Page 2: ......

Page 3: ...FOREWORD 11 ...

Page 5: ...FOREWORD FOREWORD 1 3 q Machine equipped without cab Back pocket of operator s seat ...

Page 16: ...NECESSARY INFORMATION FOREWORD 1 14 ...

Page 17: ...FOREWORD NECESSARY INFORMATION 1 15 ...

Page 24: ...CONTENTS 1 22 ...

Page 28: ...SAFETY LABELS SAFETY 2 4 SAFETY LABELS 2 POSITIONS OF SAFETY PICTOGRAMS 2 ...

Page 289: ...SPECIFICATIONS 15 ...

Page 297: ...INDEX 17 ...

Page 298: ...INDEX 7 2 ...

Page 301: ...COLOPHON 18 ...