OPERATION

OPERATION

3-111

RIPPER OPERATION

3

EFFECTIVE METHOD OF USE

3

q

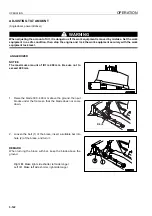

The most suitable digging angle for the shank is when the

shank is perpendicular to the ground surface (angle at tip:

45° - 50°).

q

For comparatively soft rock (seismic velocity: 1200m/s or

below), it is also possible to carry out ripping with the shank

tilted to the rear (maximum ripping angle).

q

On comparatively hard bedrock, if ripping is carried out

with the shank tilted back, there will be excessive wear of

the tip of the point (A), and this will reduce the effective-

ness of the self-sharpening ability.

q

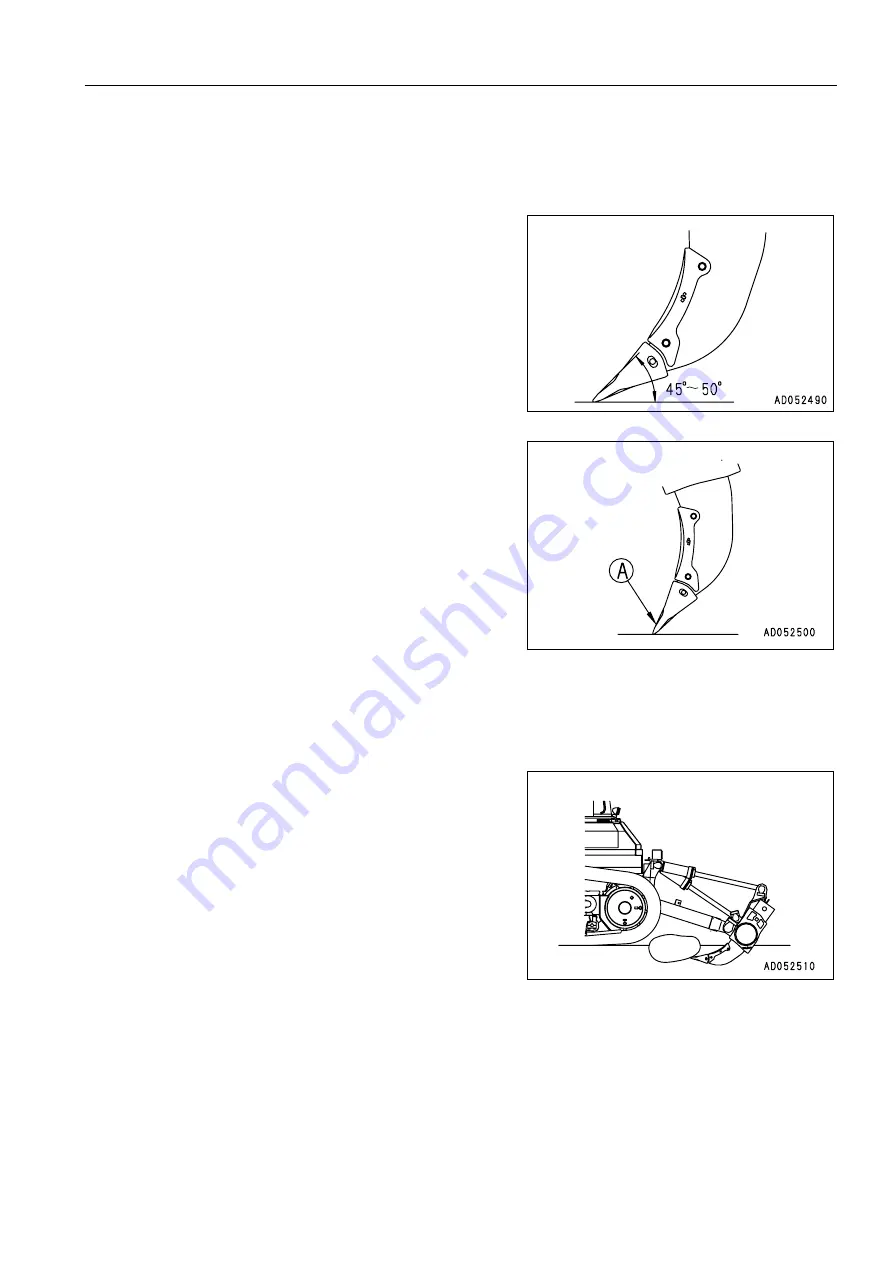

During ripping operations, if the track starts to slip when

ripping boulders or rock that is difficult to rip, use the tilt cyl-

inder.

q

Selecting a suitable ripper point to match the type of rock is

extremely important to obtain effective ripping.

A variety of ripper points to match each type of rock is

available, so use the information in “PROCEDURE FOR

SELECTING RIPPER POINT (6-6)“ to select the most suit-

able ripper point.

DIGGING UP BOULDERS OR ROCKBED

3

When ripping boulders and rockbed that are difficult to rip, if the

track slips or the travel speed becomes slower, operate the tilt

cylinder to lift up the boulder or rockbed.

Summary of Contents for 76243

Page 2: ......

Page 3: ...FOREWORD 11 ...

Page 5: ...FOREWORD FOREWORD 1 3 q Machine equipped without cab Back pocket of operator s seat ...

Page 16: ...NECESSARY INFORMATION FOREWORD 1 14 ...

Page 17: ...FOREWORD NECESSARY INFORMATION 1 15 ...

Page 24: ...CONTENTS 1 22 ...

Page 28: ...SAFETY LABELS SAFETY 2 4 SAFETY LABELS 2 POSITIONS OF SAFETY PICTOGRAMS 2 ...

Page 289: ...SPECIFICATIONS 15 ...

Page 297: ...INDEX 17 ...

Page 298: ...INDEX 7 2 ...

Page 301: ...COLOPHON 18 ...