SERVICE PROCEDURE

MAINTENANCE

4-52

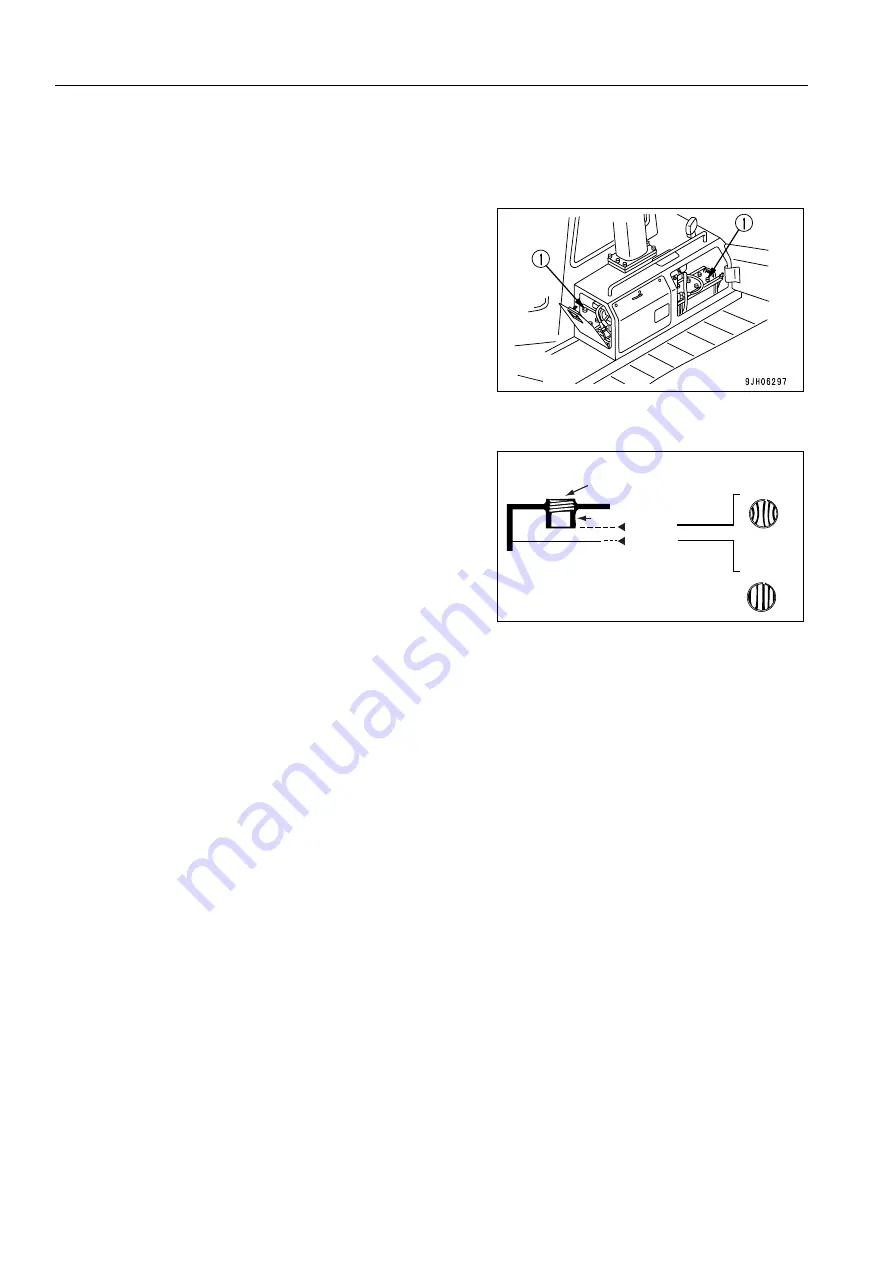

WHEN IT IS IMPOSSIBLE TO CHECK ELECTROLYTE LEVEL FROM SIDE OF BATTERY

If it is impossible to check the electrolyte level from the side of the battery, or there is no display of the UPPER

LEVEL line on the side of the battery, check as follows.

1.

Remove cap (1) on the top of the battery, look through the

water filler port, and check the electrolyte surface. If the

electrolyte does not reach the sleeve, add distilled water so

that the level reaches the bottom of the sleeve (UPPER

LEVEL line) without fail.

Use the diagram below for reference, and check if the electrolyte reaches the bottom of the sleeve.

2.

After adding distilled water, tighten cap (1) securely.

REMARK

If distilled water is added to above the bottom of the sleeve, use a syringe to lower the level to the bottom of the

sleeve. Neutralize the removed fluid with baking soda (sodium bicarbonate), then flush it away with a large amount

of water or consult your Komatsu distributor or battery maker.

WHEN IT IS POSSIBLE TO USE INDICATOR TO CHECK ELECTROLYTE LEVEL

If it is possible to use an indicator to check the electrolyte level, follow the instructions given.

A

B

Filler port

Sleeve

Upper

Lower

A

Correct level

The electrolyte level is up to the bottom of the sleeve,

so the surface tension causes the surface to rise and

the plate appears to be warped.

B

Too low (level)

The electrolyte level is not up to the bottom of the

sleeve, so the plate appears to be normal.

Summary of Contents for 76243

Page 2: ......

Page 3: ...FOREWORD 11 ...

Page 5: ...FOREWORD FOREWORD 1 3 q Machine equipped without cab Back pocket of operator s seat ...

Page 16: ...NECESSARY INFORMATION FOREWORD 1 14 ...

Page 17: ...FOREWORD NECESSARY INFORMATION 1 15 ...

Page 24: ...CONTENTS 1 22 ...

Page 28: ...SAFETY LABELS SAFETY 2 4 SAFETY LABELS 2 POSITIONS OF SAFETY PICTOGRAMS 2 ...

Page 289: ...SPECIFICATIONS 15 ...

Page 297: ...INDEX 17 ...

Page 298: ...INDEX 7 2 ...

Page 301: ...COLOPHON 18 ...