181

MAINTENANCE NOTES

4.2.1.3

FUEL

4.2.2 NOTES REGARDING THE HYDRAULIC SYSTEM

•

Use only permanent, ethylene glycol-based antifreeze, with corrosion inhibitors and antifoam products. The an-

tifreeze-water ratio must be 1:1 (50% antifreeze and 50% water).

•

The use of permanent antifreeze requires only the periodical change of the fluid. It is not necessary to wash the

cooling circuit.

•

Use drinkable water and in any case soft water.

•

Do not use corrosion inhibitors containing soluble oil, since they damage the rubber couplings.

•

The standards required for the use of permanent antifreeze are: SAE-J1034 and FEDERAL STANDARD O-A-

548D.

In case of doubt regarding the applicable standard for the use of antifreeze, contact your Komatsu Utility Deal-

er, who will supply you with exhaustive and precise information.

•

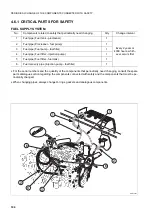

Always use fuel suitable for the engine. Other fuels with different specifications may damage the engine or re-

duce its power.

•

Always refuel at the end of the work day.

•

When refuelling, make sure that there is no water on the fuel drum cover and take care not to draw the conden-

sate from the drum bottom.

•

If fuel runs out, or if the fuel filter has been replaced, it is necessary to bleed the circuit.

•

Be extremely careful when performing maintenance operations on the hydraulic system, since soon after work

the oil is very hot.

The circuit is pressurized not only during work, but also at the end of work.

•

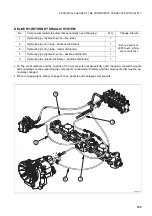

The maintenance operations required for the hydraulic system are the following:

1 - daily check of the oil level in the tank;

2 - periodical change of the oil filter;

3 - periodical change of the oil and cleaning of the suction filter.

•

Always bleed the circuit after changing the oil filter or the oil.

•

When a component is removed from the circuit, check the gaskets and O-rings and change them if they are

damaged.

•

When a cylinder or a component of the hydraulic circuit is removed, after reassembly bleed the circuit by pro-

ceeding as follows:

1 - start the engine and let it idle;

2 - make all the cylinders perform 4-5 movements, stopping them at approx. 100 mm from the end of their

stroke;

3 - slowly make all the cylinders reach the end of their stroke for 3-4 times.

Summary of Contents for 97SF11205

Page 2: ......

Page 12: ...10 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 21: ...SAFETY AND ACCIDENT PREVENTION ...

Page 56: ...54 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 57: ...THE MACHINE AND ITS OPERATIONS ...

Page 179: ...MAINTENANCE ...

Page 251: ...TECHNICAL SPECIFICATIONS ...

Page 257: ...AUTHORISED OPTIONAL EQUIPMENT ...