MAINTENANCE PLAN

200

4.7.8 MAINTENANCE EVERY 250 HOURS OF OPERATION

4.7.9 MAINTENANCE AFTER THE FIRST 500 HOURS OF OPERATION

(Only for machines in which the synthetic biodegradable oil type

HEES is used)

(Carry out these operations together with those to be performed every 500

HOURS, see “4.7.10 MAINTENANCE EVERY 500 HOURS OF OPERATION”)

4.7.10 MAINTENANCE EVERY 500 HOURS OF OPERATION

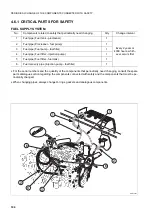

N.

PART

OPERATION

PAGE

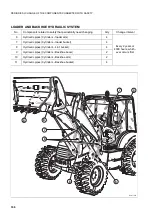

a

Fan belt

Check conditions and tension

223

b

A/C compressor belt

(only for machines with air conditioner)

Check conditions and tension

224

c

Battery

Check electrolyte level

225

d

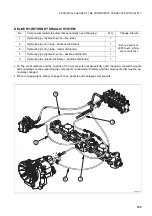

Front axle

Check levels (n. 3)

226

e

Rear axle

Check levels (n. 3)

226

f

Hydraulic transmission

Check level

227

g

Front and rear wheels

Check screw tightening

227

N.

PART

OPERATION

PAGE

a

Hydraulic oil and suction filter

(Only for machines with synthetic biodegrad-

able oil)

Change oil and clean filter

242

N.

PART

OPERATION

PAGE

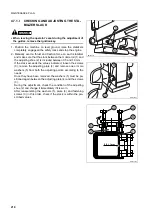

a

Engine oil

Change

229

b

Engine oil filter

Change

230

c

Hydraulic oil drain filter

Change

230

d

Fuel filter

Change

233

e

Fuel tank

Drain condensate

234

f

Hydraulic oil tank

(Only for machines with synthetic biodegrad-

able oil)

Drain condensate

235

g

Radiators

Clean outside

236

h

A/C condenser

(only for machines with air conditioner)

Clean outside

237

Summary of Contents for 97SF11205

Page 2: ......

Page 12: ...10 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 21: ...SAFETY AND ACCIDENT PREVENTION ...

Page 56: ...54 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 57: ...THE MACHINE AND ITS OPERATIONS ...

Page 179: ...MAINTENANCE ...

Page 251: ...TECHNICAL SPECIFICATIONS ...

Page 257: ...AUTHORISED OPTIONAL EQUIPMENT ...