MAINTENANCE PLAN

205

4.7.1.d

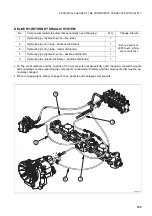

BLEEDING THE BRAKING CIRCUIT

DANGER

•

The oil spilled on the floor may cause it to become slip-

pery; immediately clean any dirty area.

•

Oils, filters, the coolant and the battery are considered

special waste and must be collected and disposed of ac-

cording to the anti-pollution regulations in force.

This operation is important, since it helps maintain the power

and braking efficiency of the machine.

Proceed as follows:

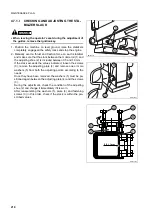

1 - Make sure that the oil in the braking system tank (3) reaches

the maximum level.

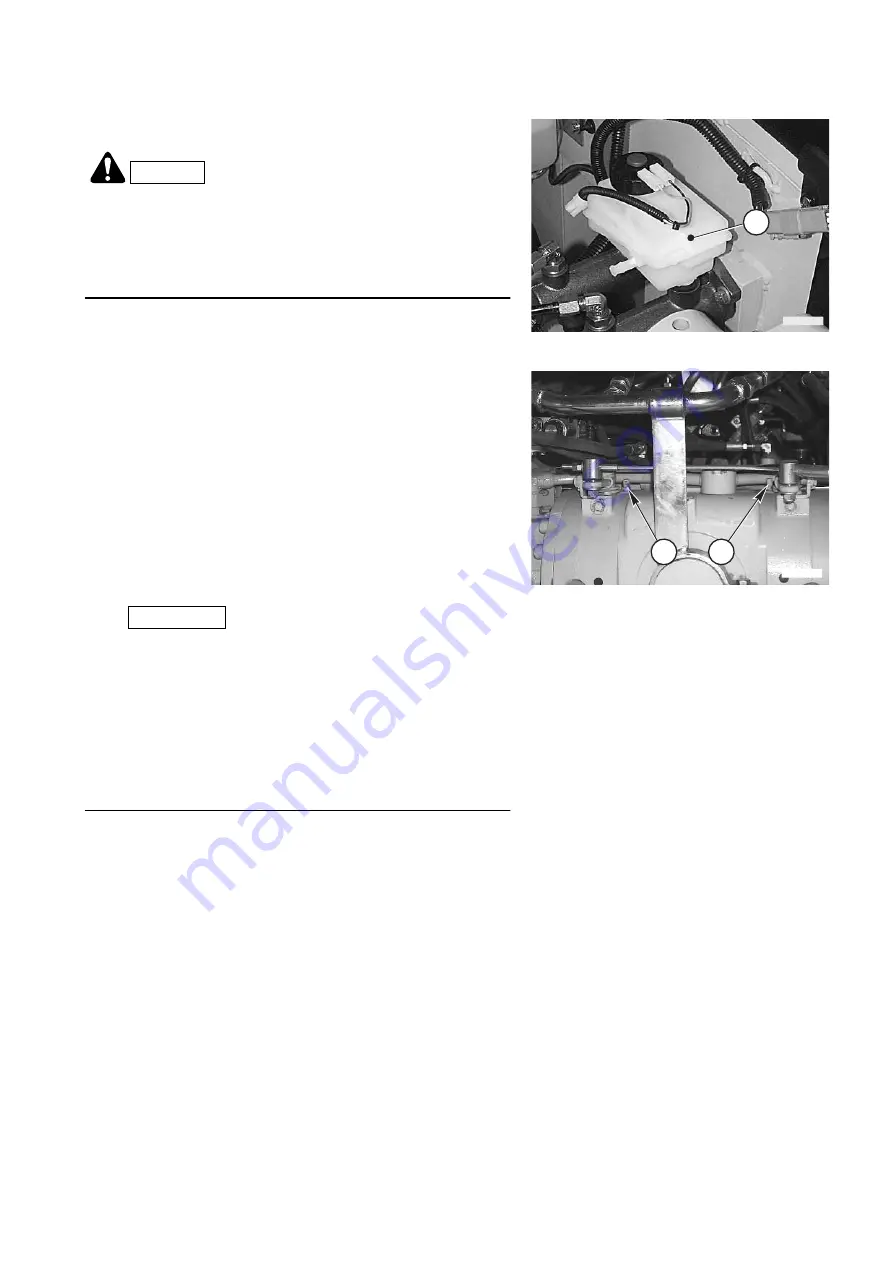

2 - Press the brake pedal thoroughly and, keeping it pressed,

loosen the drain screw (1) of the relevant brake until the ped-

al reaches the end of stroke.

Use a 13 mm spanner.

3 - Keeping the pedal at the end of its stroke, tighten the drain

screw (1).

4 - Release the brake pedal, wait for a few minutes and repeat

the operations described above until no air bubbles can be

noticed in the oil that flows out of the drain screw (1).

IMPORTANT

☞

•

When bleeding the system, apply a small pipe to the

screws (1), in order to collect the oil.

•

The bleeding must be carried out for both braking units,

disconnecting the pedals from each other.

•

Check the oil level in the braking system tank frequently

and top up whenever the oil is near the minimum level.

•

For the topping up, use only new oil of the prescribed

type.

RWAA0450

3

RWAA9090

1

1

Summary of Contents for 97SF11205

Page 2: ......

Page 12: ...10 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 21: ...SAFETY AND ACCIDENT PREVENTION ...

Page 56: ...54 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 57: ...THE MACHINE AND ITS OPERATIONS ...

Page 179: ...MAINTENANCE ...

Page 251: ...TECHNICAL SPECIFICATIONS ...

Page 257: ...AUTHORISED OPTIONAL EQUIPMENT ...