MAINTENANCE PLAN

243

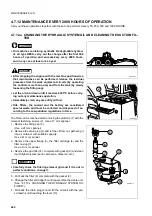

8 - Raise the front mat and remove the cover (11).

Use a 13 mm spanner

9 - Loosen the bleeder plug (12) positioned on the hydraulic

pump, until no air bubbles can be observed in the oil that

flows out (use a 3 mm setscrew spanner). Tighten the

bleeder plug (12) and put back the cover (11).

10 - Put back the filling cap (3), start the engine and operate the

machine making each piston move several times in order to

bleed the system.

Stop the machine in maintenance position, check the oil

level again and if necessary top up.

Always use oil of the prescribed type, (see “4.3 FUEL,

COOLANT AND LUBRICANTS”).

11 - Put back the upper platform (1) with the relevant fastening

screws (2).

IMPORTANT

☞

•

Do not start the engine with empty tank, since this would

certainly damage the pump.

•

The hydraulic oil must be changed when the relevant

alarm signal comes on on the electronic display posi-

tioned on the front dashboard. After performing this main-

tenance operation, set the partial service hours to zero.

For further details, see “3.3.1 FRONT INSTRUMENTS”

pos. 17.

RWA28710

3

RWA28680

1

2

RWAA9010

11

RWAA10920

12

Summary of Contents for 97SF11205

Page 2: ......

Page 12: ...10 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 21: ...SAFETY AND ACCIDENT PREVENTION ...

Page 56: ...54 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 57: ...THE MACHINE AND ITS OPERATIONS ...

Page 179: ...MAINTENANCE ...

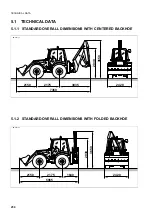

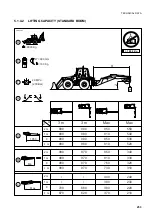

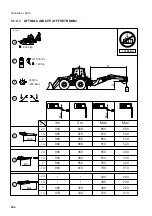

Page 251: ...TECHNICAL SPECIFICATIONS ...

Page 257: ...AUTHORISED OPTIONAL EQUIPMENT ...