257

FRONT EQUIPMENT QUICK COUPLING DEVICES

6.2

FRONT EQUIPMENT QUICK

COUPLING DEVICES

6.2.1 MANUAL CONTROL QUICK COU-

PLING

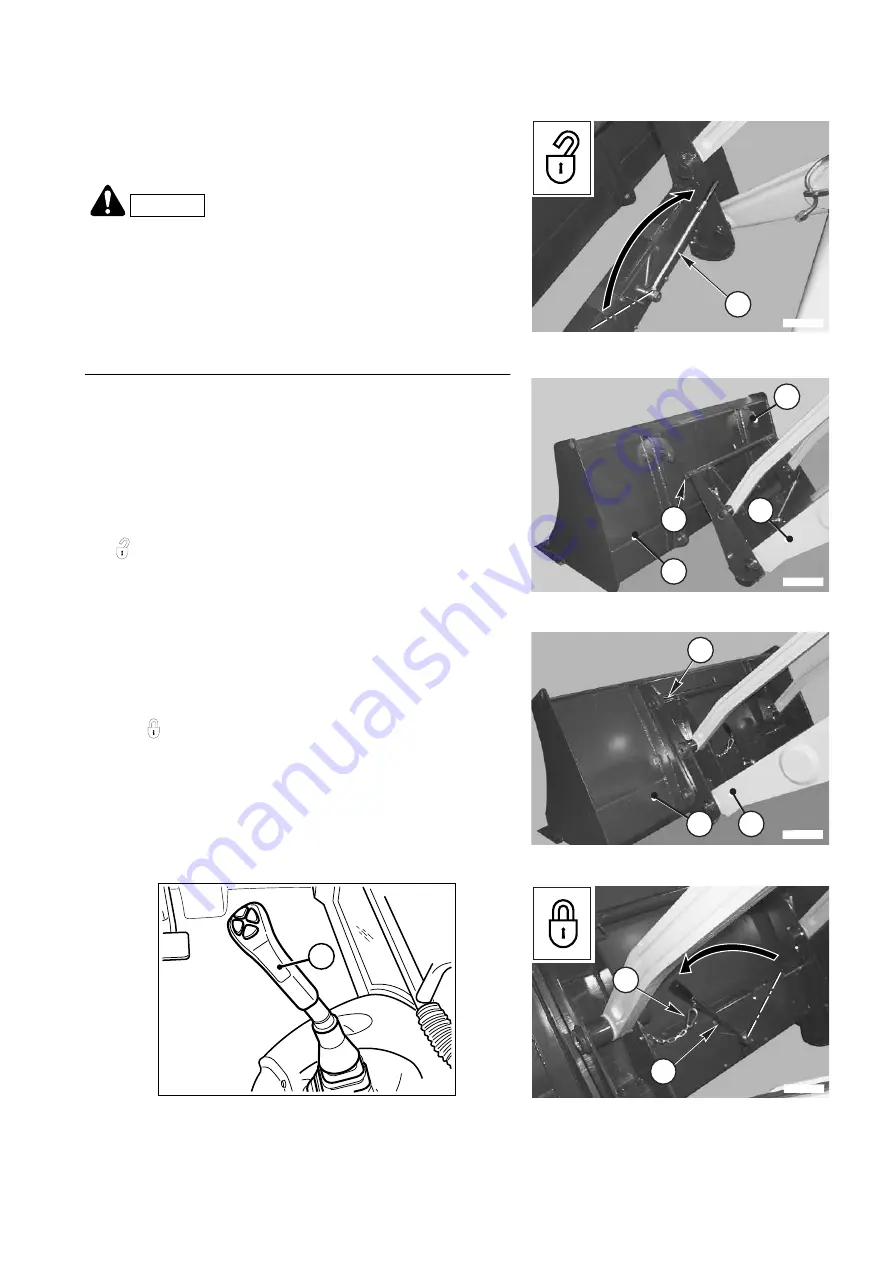

DANGER

•

The coupling and uncoupling operations must be per-

formed on a firm and level surface.

•

The method described is valid for all the front equipment

whose operation does not require the use of pressurized

oil.

•

Before starting work, make sure that the coupling pins are

completely engaged in the equipment seats.

RWAA9220

1

RWAA9210

1

7

1 - Turn the lever (1) in such a way as to make the fulcrum pins

(

)move backwards.

2 - Start the machine and position it so that it is perfectly perpen-

dicular to the equipment to be installed.

3 - With the bucket control lever (2), operate in such a way as to

position the fixed coupling pins (3) under the upper seats (4)

on the bucket (5).

4 - Raise the bucket lifting arm (6) to engage the fixed pins (3) in

the upper seats (4) on the bucket (5); raise the bucket slightly.

5 - Turn the lever (1) to the end of stroke to engage the fulcrum

pins (

).

6 - Hook the lever (1) with the appropriate safety hook (7).

7 - Lubricate the unit (see “4.5.3 LUBRICATION DIAGRAM”).

RWA31440

2

RWAA9240

5

6

3

4

RWAA9230

5

6

3

Summary of Contents for 97SF11205

Page 2: ......

Page 12: ...10 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 21: ...SAFETY AND ACCIDENT PREVENTION ...

Page 56: ...54 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 57: ...THE MACHINE AND ITS OPERATIONS ...

Page 179: ...MAINTENANCE ...

Page 251: ...TECHNICAL SPECIFICATIONS ...

Page 257: ...AUTHORISED OPTIONAL EQUIPMENT ...