266

BACKHOE TELESCOPIC ARM

6.5

BACKHOE TELESCOPIC ARM

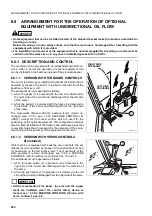

6.5.1 DESCRIPTION AND CONTROL

6.5.1.1

VERSION WITH STANDARD CONTROLS

6.5.1.2

VERSION WITH SERVO CONTROLS

(if installed)

This configuration of the backhoe arm makes it possible to work

with the equipment installed at a variable distance longer than

the distance available with the standard arm.

With the application of this arm (and with extended arm), the

breakout force at the bucket pin is reduced and only lighter loads

can be handled; therefore, it is necessary to install a suitable

bucket (see “6.1 AUTHORIZED OPTIONAL EQUIPMENT”).

This construction features an external hollow arm (1) into which

the arm (2) supporting the equipment slides on adjustable “V”-

shaped guides.

The sliding of the arm is achieved by means of a double-acting

cylinder controlled by an additional distributor.

1

RWA03550

2

The distributor that manages the telescopic movement is con-

trolled by means of a pedal (3) positioned on the right side of the

backhoe control lever unit; the movements of the levers de-

scribed in “3.3.5.1 (pos.15-16) BACKHOE CONTROL LEVERS”

remain unchanged.

The movements of the telescopic arm are controlled as follows:

1 - The extension of the arm is obtained by pressing the pedal

(3) with the toe.

2 - The retraction of the arm is obtained by pressing the pedal

(3) with the heel.

RWA35070

3

If the machine is equipped with backhoe servo controls, the

movement of the telescopic arm is achieved by means of the

push buttons (4) and (5) positioned on the right joystick lever.

The movements of the main equipment remain unchanged, see

“3.3.5.2 MACHINE CONTROLS (Version with servo controls)”

pos.15 and 16.

The movements of the telescopic arm are controlled as follows:

1 - The extension of the arm is obtained by pressing the push

button (4), while the arm stops when the button is released.

2 - The retraction of the arm is obtained by pressing the push

button (5), while the arm stops when the button is released.

IMPORTANT

☞

•

All the movements of the boom, the arm and the equip-

ment are inhibited when the control safety device is

locked, see “3.3.5.2 MACHINE CONTROLS (Version with

servo controls)” pos. 26.

RWA38100

4

5

Summary of Contents for 97SF11205

Page 2: ......

Page 12: ...10 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 21: ...SAFETY AND ACCIDENT PREVENTION ...

Page 56: ...54 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 57: ...THE MACHINE AND ITS OPERATIONS ...

Page 179: ...MAINTENANCE ...

Page 251: ...TECHNICAL SPECIFICATIONS ...

Page 257: ...AUTHORISED OPTIONAL EQUIPMENT ...