277

ARRANGEMENT FOR THE INSTALLATION OF THE DEMOLITION HAMMER

6.6.3.2

REMOVING THE HAMMER

6.6.4 USING

THE

HAMMER

6.6.5 MAINTENANCE

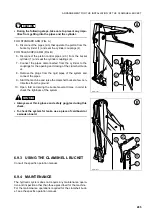

To remove the hammer, proceed as follows:

1 - Stop the engine and move the hydraulic controls in all directions, in order to completely release the residual

pressures present in the circuits of the machine.

2 - Press the hammer control pedal to release the pressure present in the hammer delivery pipe.

IMPORTANT

☞

•

If the machine is equipped with backhoe servo controls, to release the residual pressure from the cir-

cuits, follow the procedure indicated in the previous paragraph “6.6.3.1 ASSEMBLY”.

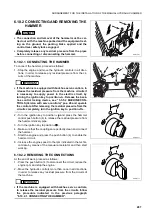

3 - Disconnect the hammer delivery and drain pipes.

4 - Fit the pipe sealing plugs complete with the relevant gaskets.

DANGER

•

Make sure that the plugs are properly tightened and that there are no leakages; if the circuit is inadvert-

ently pressurized, small leakages can be turned into thin jets that may perforate the skin or injure the

eyes.

•

Always wear thick gloves and safety goggles to carry out this check.

•

To check the system for leaks, use a piece of cardboard or a wooden board.

5 - Disconnect the hammer from the mechanical constraints, as described in “3.13.5 CHANGING THE BACK-

HOE BUCKET”.

See the specific manual.

OPERATIONS WITH THE HYDRAULIC HAMMER AND COMPACTING TOOLS

CAUTION

•

If the machine is provided with telescopic arm, this must be kept only folded.

The hydraulic system does not require any maintenance operation and inspection other than those prescribed for

the machine.

For the maintenance operations required by the hammer, see the specific operation manual.

Summary of Contents for 97SF11205

Page 2: ......

Page 12: ...10 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 21: ...SAFETY AND ACCIDENT PREVENTION ...

Page 56: ...54 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 57: ...THE MACHINE AND ITS OPERATIONS ...

Page 179: ...MAINTENANCE ...

Page 251: ...TECHNICAL SPECIFICATIONS ...

Page 257: ...AUTHORISED OPTIONAL EQUIPMENT ...