PRECAUTIONS TO BE TAKEN WHEN WORKING

36

2.4.3 CHECKS FOR TRAVELLING IN RE-

VERSE

2.4.4 MOVING

THE

MACHINE

RWA25860

•

When operating in areas that may be hazardous or have poor

visibility, designate a person to direct the movements of the

machine and traffic on the work site.

•

Before moving the machine, sound the horn to warn the per-

sons standing or working in the area.

•

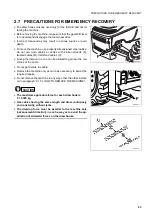

There are blind spots behind the machine, which cannot be

seen through the rear-view mirrors and where someone may

be standing.

It is necessary to make sure that there is no one behind the

machine before travelling in reverse.

On request the machine may be equipped with an acoustic

alarm (1) to be used in case of reversal. If the machine is

equipped with this acoustic alarm (1), before any reversal

make sure that it functions correctly.

See “3.3.5 pos. 1 REVERSING GEAR LEVER” to check the

functionality of the alarm.

RWAB0630

1

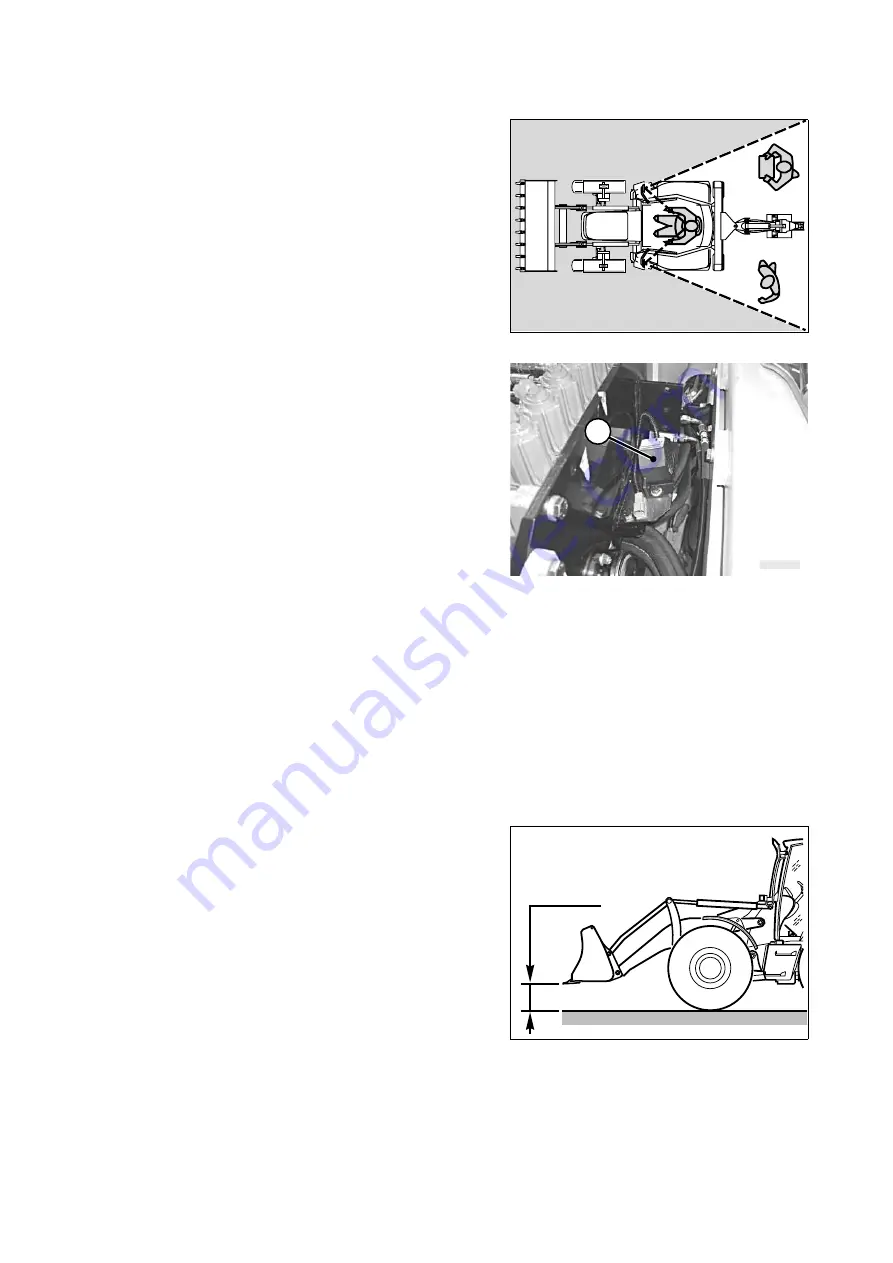

30÷40 cm

RWA25870

•

When moving the machine, position the front bucket at about

30÷40 cm from the ground; this position makes it possible to

evaluate the space required for the movements more precisely

and at the same time ensures the stability of the machine.

•

If the front bucket control lever is to be used during travel,

avoid moving it abruptly; sudden manoeuvres change the atti-

tude of the machine and make driving difficult.

•

When travelling on rough ground, keep the speed low and

avoid sudden movements of the bucket arm.

•

If the machine has to travel over an obstacle, keep the front

equipment as close to the ground as possible and travel at low

speed, in order not to strain the axles and tyres.

Summary of Contents for 97SF11205

Page 2: ......

Page 12: ...10 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 21: ...SAFETY AND ACCIDENT PREVENTION ...

Page 56: ...54 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 57: ...THE MACHINE AND ITS OPERATIONS ...

Page 179: ...MAINTENANCE ...

Page 251: ...TECHNICAL SPECIFICATIONS ...

Page 257: ...AUTHORISED OPTIONAL EQUIPMENT ...