PRECAUTIONS TO BE TAKEN DURING MAINTENANCE

45

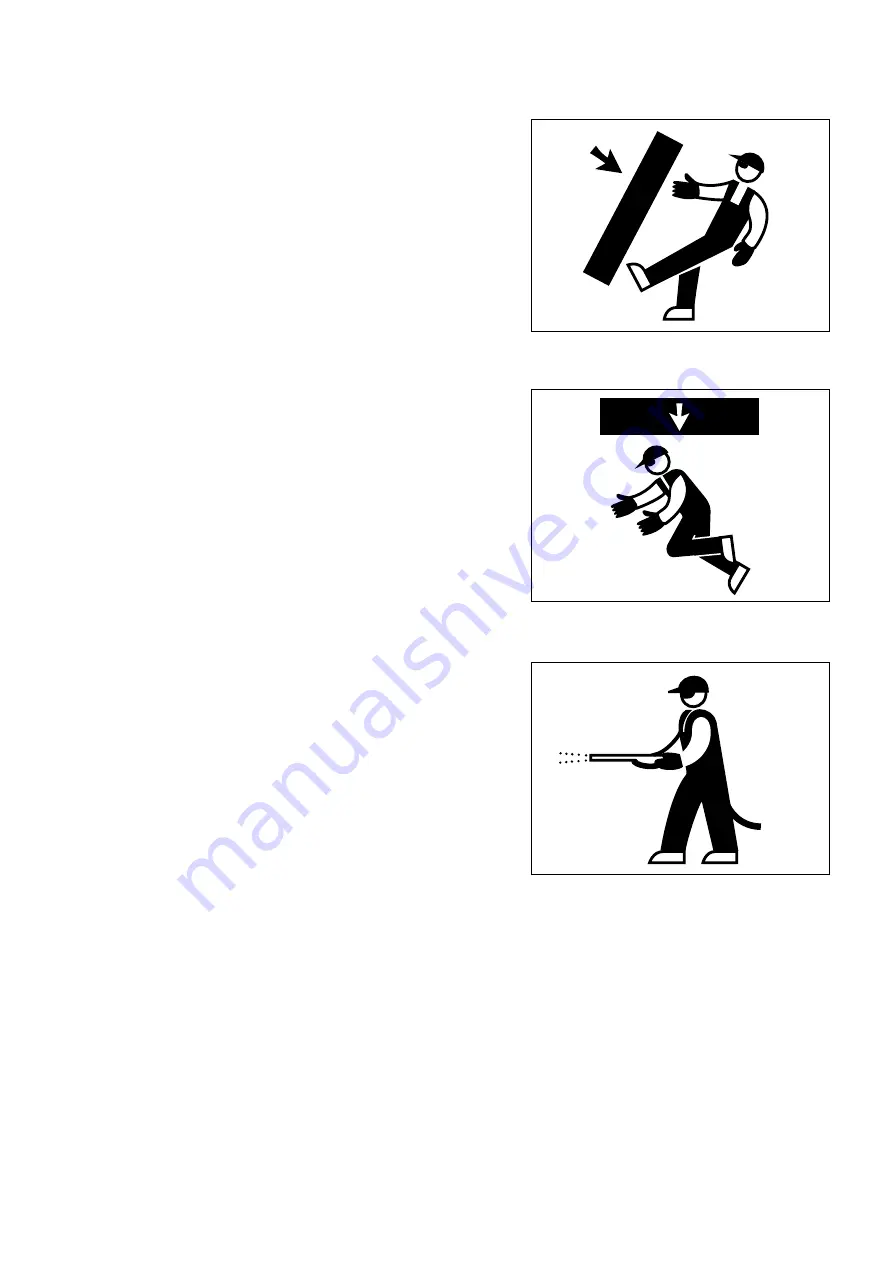

2.8.4 EQUIPMENT

2.8.5 WORKING UNDER THE MACHINE

2.8.6 KEEPING THE MACHINE CLEAN

RWA01320

•

The normal or special equipment that must be installed on the

machine or that have been removed must be stored in safe

places, preventing them from falling down. If they fall on some-

one, they can cause serious bodily harm.

•

When assemblying or removing any equipment, make sure

that the ropes and the lifting hook are in good conditions and

properly dimensioned for the load to be lifted.

RWA02520

•

Always lower the work equipment to the ground or in any case

to their lowest position before performing service or repairs un-

der the machine.

•

Always lock the machine tyres securely.

•

Do not work under the machine, if this is not sufficiently sup-

ported.

RWA01330

•

Spilled oil or grease, scattered tools or broken pieces are dan-

gerous, because they may cause someone to slip or trip. Al-

ways keep the machine and the work site clean and tidy.

•

To clean the machine, use a pressurized jet of warm water or

steam and the appropriate detergents available on the market.

Do not use gas oil, oil or solvents, since the former leave an

oily coat that favours the sticking of dust, while the latter (even

if weak) damage the painted surfaces and therefore facilitate

rusting.

•

While cleaning the machine, keep the pressurized jet at a min-

imum distance of approx. 60 cm in order not to damage the

warning plates and the pictograms.

If the plates are damaged, request Komlatsu Utility or your

Komlatsu Utility Dealer to send you spare plates and change

them.

•

Water into the electrical system provokes the oxidation of the

contacts and may hinder the start of the machine or even

make it start suddenly and abruptly. For this reason, never use

water or steam jets to clean sensors, connectors or the inside

of the operator’s cab.

Summary of Contents for 97SF11205

Page 2: ......

Page 12: ...10 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 21: ...SAFETY AND ACCIDENT PREVENTION ...

Page 56: ...54 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 57: ...THE MACHINE AND ITS OPERATIONS ...

Page 179: ...MAINTENANCE ...

Page 251: ...TECHNICAL SPECIFICATIONS ...

Page 257: ...AUTHORISED OPTIONAL EQUIPMENT ...