PRECAUTIONS TO BE TAKEN DURING MAINTENANCE

50

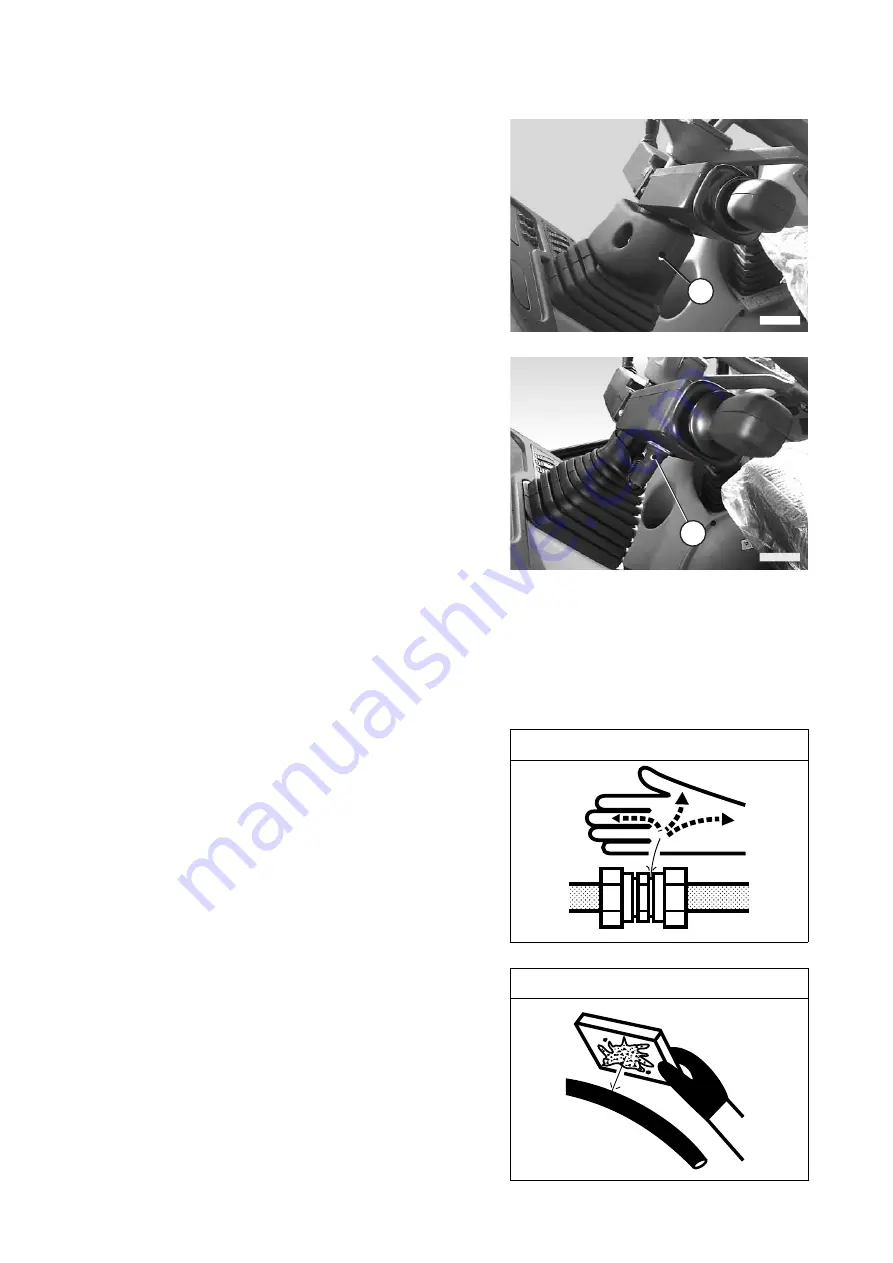

2.8.15 PRECAUTIONS CONCERNING THE

GEARSHIFT

2.8.16 HANDLING HIGH-PRESSURE PIPES

2.8.17 PRECAUTIONS TO BE TAKEN WHEN

HANDLING HIGH-PRESSURE OIL

•

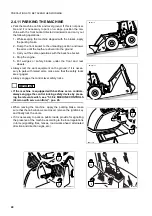

If electrical welding operations are to be carried out on the ma-

chine, it is necessary to disconnect the connector (1) of the

gearshift unit positioned under the steering wheel.

To reach the connector (1), first remove the protection casing

(2).

RWAA9260

2

RWAA0970

1

•

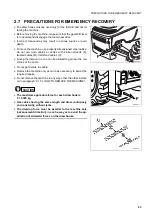

Do not bend high-pressure pipes or rub them with abrasive or cutting objects.

Do not use any bent or cracked pipes or hoses that were previously rejected because of leaks or fastening de-

fects, since they may burst during use.

•

Always repair or replace any loose or faulty fuel or oil pipe. Any leakage of fuel or oil may cause fires.

RWA01480

DANGEROUS!

RWA01580

CORRECT

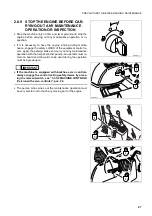

•

Do not forget that the work equipment circuits are always un-

der pressure; for this reason, when it is necessary to add or

drain hydraulic oil or to perform maintenance operations or in-

spections on the hydraulic circuit, it is advisable to lower the

equipment to the ground and completely release the pressures

and the residual pressure present in the tank.

Small leakages from pipes under pressure and the resulting

jets are extremely dangerous, since they can perforate the skin

and penetrate in the blood circulation or injure the eyes.

For this reason, always wear goggles and thick gloves during

the inspections and use a piece of cardboard or a sheet of ply-

wood to check for oil leakages.

If you are hit by a jet of high-pressure oil or are injured, even if

slightly, immediately consult a doctor.

Summary of Contents for 97SF11205

Page 2: ......

Page 12: ...10 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 21: ...SAFETY AND ACCIDENT PREVENTION ...

Page 56: ...54 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 57: ...THE MACHINE AND ITS OPERATIONS ...

Page 179: ...MAINTENANCE ...

Page 251: ...TECHNICAL SPECIFICATIONS ...

Page 257: ...AUTHORISED OPTIONAL EQUIPMENT ...