182

MAINTENANCE NOTES

4.2.3 NOTES REGARDING THE ELECTRICAL SYSTEM

4.2.4 NOTES REGARDING LUBRICATION

•

If the cables are wet or their insulating material is damaged, the electrical system leaks and this may result in

malfunctions of the machine.

•

The maintenance operations required for the electrical system are the following:

1 - check of the alternator belt tension;

2 - check of the alternator belt for damage or breakages;

3 - check of the battery electrolyte level.

•

Do not remove or eliminate any electric component installed on the machine and do not install any electric com-

ponent with characteristics different from those specified and approved by Komatsu Utility.

•

Be careful to keep the electric system dry.

•

When working on seashores or river or lake banks, protect the jack plugs from corrosion.

•

Do not connect any optional device to the fuses, ignition switch, battery, relays, etc.; for the installation of any

optional equipment, contact your Komatsu Utility Dealer.

•

If any electric welding operation has to be carried out, disconnect the battery, the alternator and the gearshift-

reversing gear connector.

•

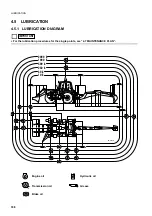

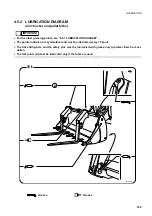

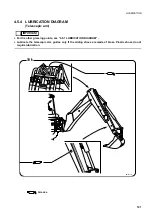

Lubrication makes the operations carried out with the machine and work equipment smoother, while preventing

wear and the noise that may be produced if the articulations are dry.

Lubrication is to be carried out with grease or oil.

•

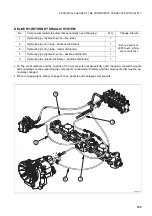

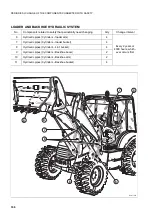

The maintenance operations required for the components that need lubricating are the following:

1 - check of the levels;

2 - oil change;

3 - injection of grease through the grease nipples.

•

Use only the specified lubricants, according to the ambient temperature.

•

Always clean the grease nipples before injecting grease and remove any excess grease after lubrication; this

cleaning operation must be performed with extreme care on the revolving parts.

•

Keep the lubricants at the correct levels; excessive or insufficient quantities are to be avoided.

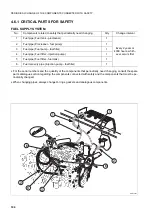

Summary of Contents for 97SF11205

Page 2: ......

Page 12: ...10 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 21: ...SAFETY AND ACCIDENT PREVENTION ...

Page 56: ...54 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 57: ...THE MACHINE AND ITS OPERATIONS ...

Page 179: ...MAINTENANCE ...

Page 251: ...TECHNICAL SPECIFICATIONS ...

Page 257: ...AUTHORISED OPTIONAL EQUIPMENT ...