MAINTENANCE PLAN

206

4.7.1.e

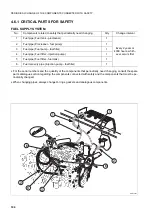

CLEANING THE WATER SEPARATOR

4.7.1.f

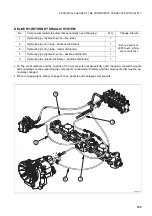

CHECKING AND ADJUSTING THE

WHEEL TOE-IN

RWAA0760

3

4

2

1

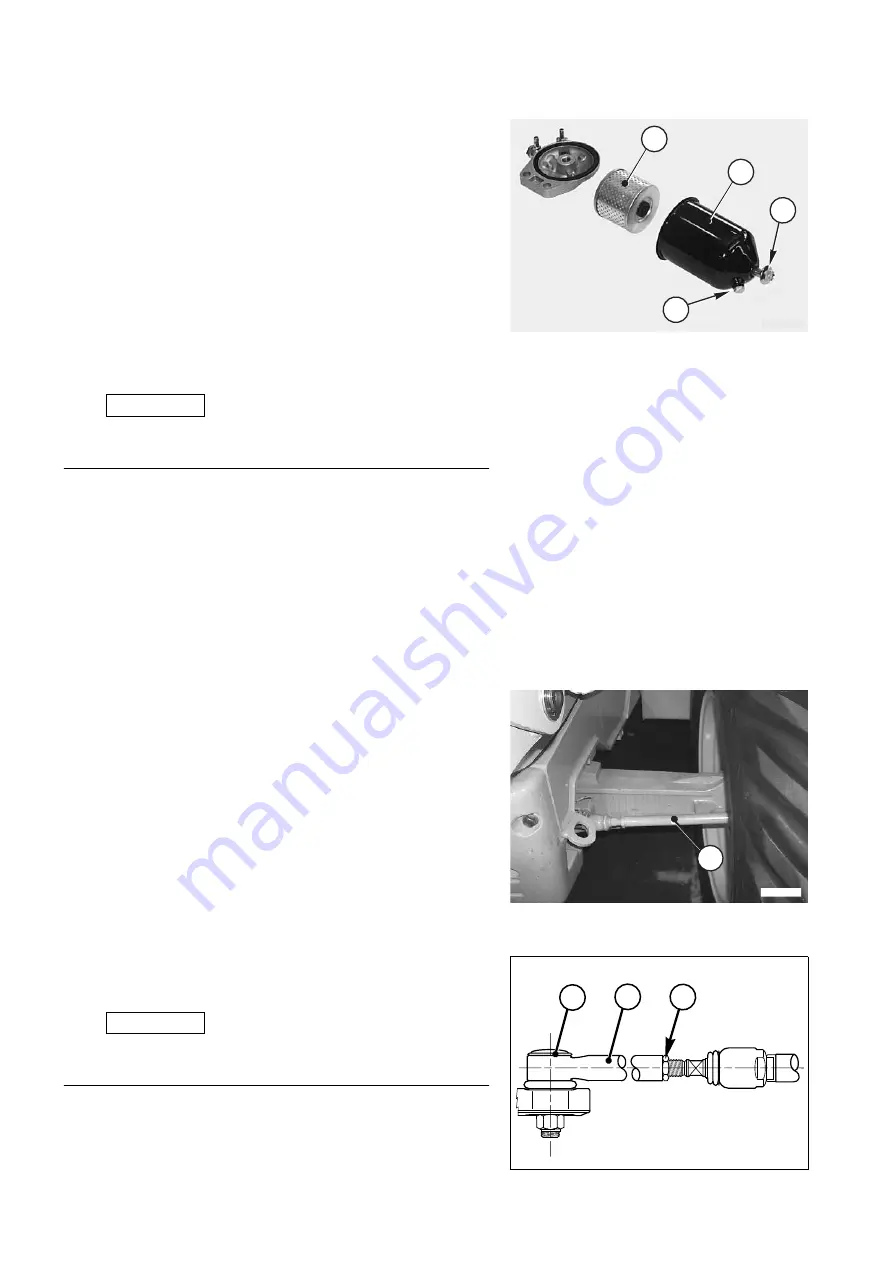

1 - Loosen the screw (1) and drain the fuel contained in the wa-

ter separator, gathering it in a container with suitable capaci-

ty.

Use a 13 mm spanner.

2 - Loosen the central screw (2) and remove the bowl (3) and the

filtering element (4).

3 - Clean the inside of the pan and the filter with diesel oil or

oil.

4 - Put back the filter (4) and the bowl (3), tighten the screws (2)

and (1) and bleed the fuel supply circuit proceeding as de-

scribed in chapter “4.7.10.d CHANGING THE FUEL FILTER”.

5 - Start the engine.

IMPORTANT

☞

•

If the filtering element is excessively clogged or damaged,

provide for changing it.

This check must be carried out according to time intervals fixed

by the operator, since any anomaly regarding the wheel toe-in is

due to impacts or vibrations that depend on the type of surface

on which the machine works.

Another reason that shoud lead the operator to perform this

check is the excessive wear of the tyres.

The machine has been designed with a toe-in equal to 0 mm.

Every adjustment must restore this value and must be carried

out on the coupling bars (1) after loosening the nuts (2) that lock

them. (Use 27 and 36 mm spanners).

During this check and the relevant adjustment, it is advisable to

check also the conditions of the articulated heads (3); if a con-

siderable slack is observed, immediately provide for changing

them.

IMPORTANT

☞

•

Check the toe-in and if necessary carry out the required

adjustment on both axles.

RWAA9080

1

RWA02980

3

1

2

Summary of Contents for 97SF11205

Page 2: ......

Page 12: ...10 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 21: ...SAFETY AND ACCIDENT PREVENTION ...

Page 56: ...54 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 57: ...THE MACHINE AND ITS OPERATIONS ...

Page 179: ...MAINTENANCE ...

Page 251: ...TECHNICAL SPECIFICATIONS ...

Page 257: ...AUTHORISED OPTIONAL EQUIPMENT ...