MAINTENANCE PLAN

198

4.7.5 MAINTENANCE AFTER THE FIRST 50 HOURS OF OPERATION

(Only for machines in which the synthetic biodegradable oil type

HEES is used)

4.7.6 MAINTENANCE EVERY 50 HOURS OF OPERATION

4.7.6.a

CHECKING THE RADIATOR FLUID LEVEL

4.7.6.b

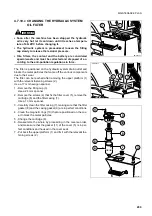

CHECKING THE BRAKING SYSTEM OIL

LEVEL

The following maintenance operation must be carried out after the first 50 hours of operation, together with the

maintenance operations to be carried out “EVERY 50 HOURS”.

•

HYDRAULIC OIL DRAIN FILTER CHANGE

For further details on the various maintenance operations, see section “EVERY 500 HOURS”.

DANGER

•

Carry out this check with the machine parked on level

ground and loader arm raised with engaged safety lock.

•

Do not remove the radiator cap when the fluid is hot,

since the fluid may be sprayed out of the radiator and

cause burns.

•

Loosen the cap slowly to release the pressure before re-

moving it.

The radiator cap can be reached after opening the engine hood

(See “3.5.1 ENGINE HOOD”).

Remove the cap (1) and make sure that the fluid is very near the

filling hole.

IMPORTANT

☞

•

If the level of the fluid in the radiator is low and the expan-

sion tank is filled with coolant, check the tightness and

make sure that there are no air leaks from the coupling

that connects the radiator and the expansion tank.

If the problem persists, contact your Komatsu Utility Deal-

er.

1

RWAA10960

The brake reservoir (1) can be reached after opening the engine

hood (See “3.5.1 ENGINE HOOD”).

This is a visual check and the reservoir must be topped up with

the prescribed fluid until reaching the MAX. mark (See “4.3 FU-

EL, COOLANT AND LUBRICANTS”).

IMPORTANT

☞

•

Use new oil only.

•

If constant and considerable leakages are observed, it is

advisable to contact an Komatsu Utility Dealer to have the

system checked and the necessary repairs carried out.

1

RWAA0250

Summary of Contents for Avance WB91R-2

Page 2: ......

Page 12: ...10 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 21: ...SAFETY AND ACCIDENT PREVENTION ...

Page 56: ...54 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 57: ...THE MACHINE AND ITS OPERATIONS ...

Page 124: ...122 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 159: ...MAINTENANCE ...

Page 229: ...TECHNICAL SPECIFICATIONS ...

Page 238: ...236 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 239: ...AUTHORISED OPTIONAL EQUIPMENT ...