265

ARRANGEMENT FOR THE OPERATION OF OPTIONAL EQUIPMENT WITH UNIDIRECTIONAL OIL FLOW

6.8.2 INSTALLING AND CONNECTING

THE EQUIPMENT

6.8.3 MAINTENANCE

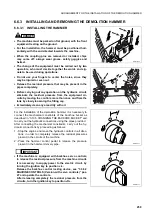

The equipment must be installed following the procedure indicat-

ed in paragraph “3.13.5 CHANGING THE BACKHOE BUCKET”.

Connect the delivery and return pipes by proceeding as follows:

1 - After connecting the equipment, stop the engine and shift the

hydraulic controls in all directions, in order to release the re-

sidual pressure from the machine circuits.

IMPORTANT

☞

•

If the machine is equipped with backhoe servo controls,

to release the residual pressure from the machine circuits

it is necessary to supply power to the electric circuit, by

turning the ignition key to position «I».

Release the backhoe control locking device, see “3.3.6.2

MACHINE CONTROLS (Version with servo controls)” pos.

27 and operate the controls.

After releasing the residual pressure completely from the

circuits, turn the ignition key to position «O».

CAUTION

•

During the successive steps, take care to prevent any im-

purities from getting into the circuit.

2 - Remove the plugs of the two pipes and of the installed equip-

ment.

3 - Connect the delivery and return pipes.

4 - Start the machine, carry out several manoeuvres with the

pedal (1) or with the buttons (2-3) used to control the equip-

ment, in order to verify the tightness of the circuits.

DANGER

•

Wear thick gloves and safety goggles during this check.

•

To check the system for leaks, use a piece of cardboard or

a wooden board.

5 - Stop the machine and if necessary fasten the longer pipes in

order to avoid vibrations and therefore critical conditions for

the coupling connections.

RWA38120

RWA38130

RWA01960

RWA02000

The hydraulic system does not require any maintenance opera-

tion and inspection other than those prescribed for the machine.

For the maintenance operations required by the equipment, see

the specific operation manuals.

Summary of Contents for Avance WB91R-2

Page 2: ......

Page 12: ...10 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 21: ...SAFETY AND ACCIDENT PREVENTION ...

Page 56: ...54 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 57: ...THE MACHINE AND ITS OPERATIONS ...

Page 124: ...122 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 159: ...MAINTENANCE ...

Page 229: ...TECHNICAL SPECIFICATIONS ...

Page 238: ...236 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 239: ...AUTHORISED OPTIONAL EQUIPMENT ...