230

TECHNICAL DATA

5.1.2.2

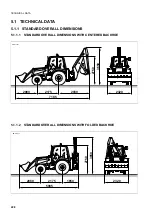

TECHNICAL CHARACTERISTICS WB93R-2

TOTAL MASS

Minimum total mass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . kg

7400

Maximum total mass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . kg

8800

STANDARD BUCKET CAPACITY

Front bucket capacity (SAE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . m

3

1.03

Backhoe bucket capacity (SAE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . m

3

0.20

TURBOCHARGED ENGINE

Komatsu diesel engine model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S4D106-2SFA

Maximum power (2200 rpm EEC 80/1269) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . kW

72

Maximum torque (1500±100 rpm EEC 80/1269) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Nm

375

ELECTRICAL SYSTEM

Alternator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12V

Electrical output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

80 A

Earthing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

negative

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .160 Ah - 12V

Starter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . kW

3.0

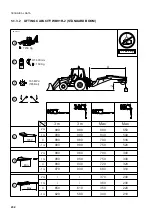

TRAVEL SPEEDS

(calculated with 18.4-26 tyres and engine at 2200 rpm)

GEARS 1

a

2

a

3

a

4

a

R1

R2

R3

R4

km/h

6

11

21

39

6

11

21

39

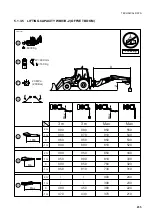

FRONT TYRES

SIZE

MAKE

INFLATION PRESSURE

Std.

12.5/80-18

PR 10

GOOD YEAR

bar 3.1

Opt.

365/70-R18 SPT9

—

DUNLOP

bar 3.75

REAR TYRES

SIZE

MAKE

INFLATION PRESSURE

Std.

16.9-28

PR 12

GOOD YEAR

bar 2.2

Opt.

18.4-26

PR12

GOOD YEAR

bar 2.5

Summary of Contents for Avance WB91R-2

Page 2: ......

Page 12: ...10 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 21: ...SAFETY AND ACCIDENT PREVENTION ...

Page 56: ...54 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 57: ...THE MACHINE AND ITS OPERATIONS ...

Page 124: ...122 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 159: ...MAINTENANCE ...

Page 229: ...TECHNICAL SPECIFICATIONS ...

Page 238: ...236 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 239: ...AUTHORISED OPTIONAL EQUIPMENT ...