246

PALLET FORKS

6.4 PALLET FORKS

6.4.1 DESCRIPTION

6.4.2 SAFETY DEVICES

(For the characteristics, see “6.1 AUTHORIZED OPTIONAL EQUIPMENT”).

CAUTION

•

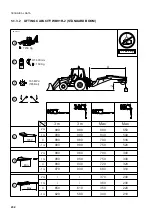

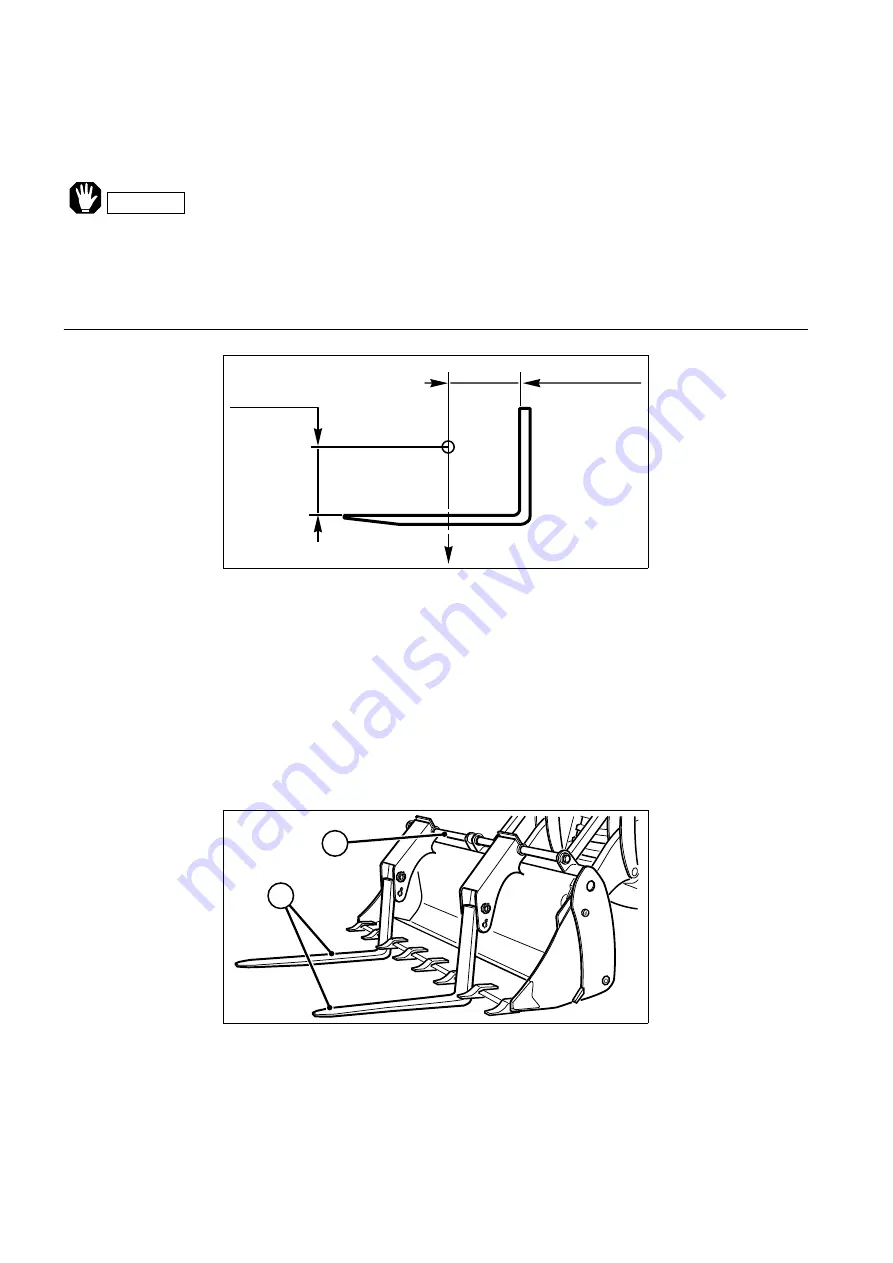

Before lifting the load, make sure that the position of its centre (G) complies with the distances indicat-

ed in the figure below. Furthermore, the load must always be centered with respect to the forks. Non-

compliance with these rules may cause serious damage and even death.

•

Before handling any load, verify the capacity of the forks. The allowed load is generally stamped on the

forks.

RWA38740

Max 500 mm

Max 500 mm

G

F

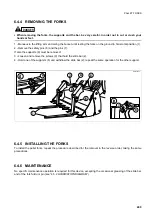

They are usually applied to the 4in1 bucket and when they are not used they must be overturned towards the

back of the machine and secured with the safety pins provided.

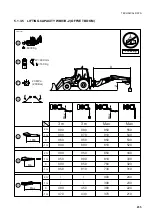

The pallet forks (1) make it possible to use the machine as a normal lift truck and the controls for the lifting and

oscillation are the same used to control the standard bucket (See “3.3.6 pos. 4 FRONT LOADER CONTROL LE-

VER”).

The distance between the pallet forks can be varied to adapt them to the load to be handled; to do this, make

them slide on the coupling bar (2).

RWA34530

1

2

For this application two safety pins (3) are provided that keep the forks in overturned position for the circulation on

roads.

Summary of Contents for Avance WB91R-2

Page 2: ......

Page 12: ...10 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 21: ...SAFETY AND ACCIDENT PREVENTION ...

Page 56: ...54 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 57: ...THE MACHINE AND ITS OPERATIONS ...

Page 124: ...122 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 159: ...MAINTENANCE ...

Page 229: ...TECHNICAL SPECIFICATIONS ...

Page 238: ...236 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 239: ...AUTHORISED OPTIONAL EQUIPMENT ...