PRECAUTIONS FOR MAINTENANCE

47

2.8.7 USE OF THE ENGINE DURING MAINTENANCE OPERATIONS

2.8.8 PERIODICAL CHANGE OF THE PARTS THAT ARE CRITICAL FOR

SAFETY

•

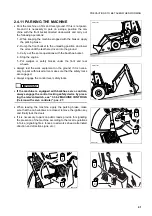

During maintenance operations, let the engine run only when it is absolutely necessary. If the engine must be

running (for example, when checking the functionality of the alternator), it is advisable that someone remains

seated in the driving position, so that the engine can be stopped whenever necessary.

•

During maintenance operations with running engine, never move the control locking devices from the “lock” po-

sition or change the position of the gearshift lever.

Service personnel must not move any control lever.

IMPORTANT

☞

•

If the machine is equipped with backhoe servo controls, always engage the control locking safety de-

vice by pressing the relevant switch, see “3.3.6.2 MACHINE CONTROLS (Version with servo controls)”,

pos. 27.

•

When carrying out maintenance operations, do not touch the moving parts of the machine and avoid wearing

large and loose clothes.

•

Periodically change the following components, which are important for safety and fire prevention:

Fuel supply system: fuel delivery and return pipes.

Hydraulic system: main delivery pipes of the hydraulic pump.

Hydraulic system: work circuit pipes from the distributor to the hydraulic cylinders.

Safety belt

•

Even if they seem to be in good conditions, these components must be periodically changed with new ones.

In fact, these components tend to deteriorate over time.

•

If one of these parts is defective, change or repair it even if the change interval has not elapsed yet. (See “4.6

PERIODICAL CHANGE OF THE COMPONENTS CONNECTED WITH SAFETY).

Summary of Contents for Avance WB91R-2

Page 2: ......

Page 12: ...10 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 21: ...SAFETY AND ACCIDENT PREVENTION ...

Page 56: ...54 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 57: ...THE MACHINE AND ITS OPERATIONS ...

Page 124: ...122 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 159: ...MAINTENANCE ...

Page 229: ...TECHNICAL SPECIFICATIONS ...

Page 238: ...236 THIS PAGE WAS INTENTIONALLY LEFT EMPTY ...

Page 239: ...AUTHORISED OPTIONAL EQUIPMENT ...