Normal or standard technical data ................... 2

Special tools........................................... 23

Checking the engine speed .......................... 25

Adjustment of valve clearance ....................... 26

Measurement of the compression pressure ........ 27

Control and adjustment of the tension of

the fan belt ............................................ 28

Control and adjustment of the injection timing ..... 29

Control and adjustment of the accelerator stroke.. 31

Adjustment of the stroke of the blade

command lever ........................................ 32

Control and adjustment of the stroke of

the travel lever ........................................ 33

Centering adjustment of the boom swing

command pedal ....................................... 34

Adjustment of the rubber pad and safety

microswitch for servo-control engagement ......... 35

Control and adjustment of the track-shoe tension . 36

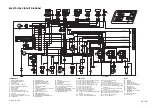

Control and regulation of pressure in the

hydraulic circuits (PC12R-8).......................... 37

Control and regulation of the pressures in the

hydraulic circuits (PC15R-8).......................... 40

Control and regulation of the LS differential

pressure and adjustment of the LS valve ........... 43

Regulation of the PC valve ........................... 45

Control and regulation of the servo-control

power supply (PC12R-8) .............................. 46

Control and regulation of the servo-control

power supply (PC15R-8) .............................. 47

Elimination of residual pressures - pressurisation

of the tank ............................................. 48

Bleeding air from the hydraulic circuits ............. 49

Control of hydraulic drifts - analysis of

the causes of a drift................................... 51

Checking for any leakages inside the

working equipment cylinders ......................... 57

Checking for any leakages inside the

swing motor............................................ 58

Methods for testing for leakages inside the

swivel joint ............................................. 59

TESTING AND ADJUSTMENTS

20-1

When carrying out controls, adjustments or analyses for troubleshooting, park the machine on firm, level

ground. Apply all the machine safety devices and use blocks to prevent any machine movement.

When more than one person is engaged in the work, use the prescribed notices that indicate that the machine

is undergoing maintenance. Do not allow any unauthorised persons to remain in the vicinity.

When checking the level of the cooling liquid, wait until this liquid has cooled. If the radiator cap is removed

while the liquid is still hot and under pressure, it may cause severe burns.

Take great care not to get entangled in moving parts (fan, alternator belt or any of the rotating elements).

PC12R-8 PC15R-8

Summary of Contents for PC12R-8 MISTRAL

Page 1: ......

Page 2: ...40 28 PC15R 8 ...

Page 4: ...00 2 PC12R 8 PC15R 8 ...

Page 17: ...GROUP 10 ...

Page 18: ...40 28 PC15R 8 ...

Page 30: ...10 12 PC12R 8 PC15R 8 PAGE INTENTIONALLY LEFT BLANK ...

Page 32: ...10 14 PC12R 8 PC15R 8 PAGE INTENTIONALLY LEFT BLANK ...

Page 34: ...10 16 PC12R 8 PC15R 8 PAGE INTENTIONALLY LEFT BLANK ...

Page 36: ...10 18 PC12R 8 PC15R 8 PAGE INTENTIONALLY LEFT BLANK ...

Page 38: ...10 20 PC12R 8 PC15R 8 PAGE INTENTIONALLY LEFT BLANK ...

Page 40: ...10 22 PC12R 8 PC15R 8 PAGE INTENTIONALLY LEFT BLANK ...

Page 42: ...10 24 PC12R 8 PC15R 8 PAGE INTENTIONALLY LEFT BLANK ...

Page 44: ...10 26 PC12R 8 PC15R 8 PAGE INTENTIONALLY LEFT BLANK ...

Page 79: ...10 61 PC12R 8 PC15R 8 PAGE INTENTIONALLY LEFT BLANK ...

Page 130: ...10 112 PC12R 8 PC15R 8 PAGE INTENTIONALLY LEFT BLANK ...

Page 132: ......

Page 133: ...GROUP 20 ...

Page 134: ...40 28 PC15R 8 ...

Page 158: ...20 24 PC12R 8 PC15R 8 PAGE INTENTIONALLY LEFT BLANK ...

Page 198: ......

Page 199: ...GROUP 30 ...

Page 200: ...40 28 PC15R 8 ...

Page 283: ...GROUP 40 ...

Page 284: ...40 28 PC15R 8 ...

Page 317: ...40 33 PC12R 8 PC15R 8 PAGE INTENTIONALLY LEFT BLANK ...

Page 324: ......