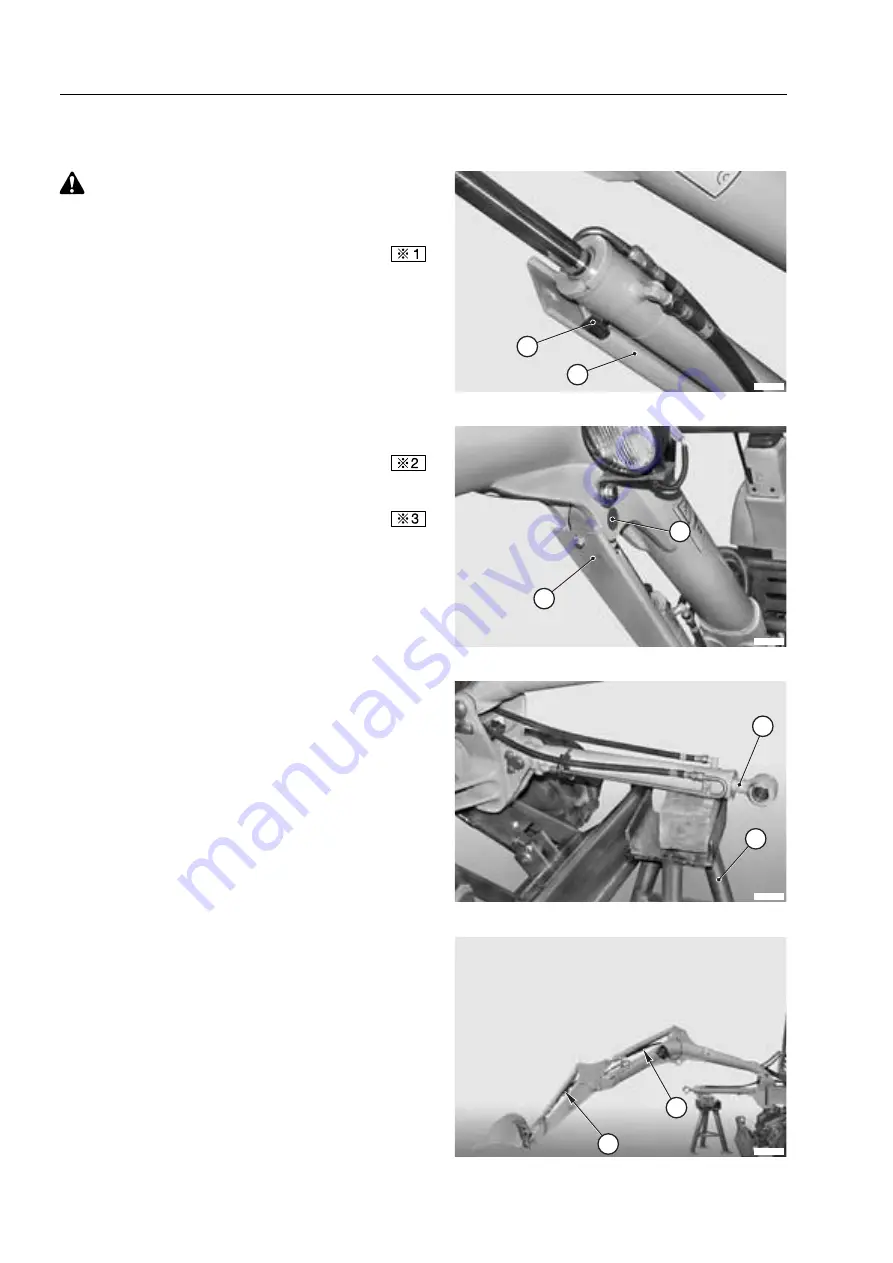

REMOVAL OF THE UPPER WORKING EQUIPMENT

Fully extend the arm and open the bucket complete-

ly. Lower the equipment until it rests on the ground.

1 - Remove the protection (1) and the relative shoes (2).

2 - Stop the engine, release the pressures in the cylinder

by moving the PPC valve lever several times.

3 - Remove the pin (3).

4 - Start the engine to retract the piston (4).

H

Bind the piston rod with wire to secure the fully re-

tracted position.

5 - Lower the cylinder (2) until it rests on a stand «A».

6 - Stop the engine and release the residual hydraulic

pressures. (For details, see «20. CONTROLS AND

ADJUSTMENTS»).

7 - Disconnect the hoses (5) and plug them. Also plug

the holes in the cylinder to prevent entry of impurities.

H

Disconnect the hoses from any optionalequip-

ment. Plug the hoses and the unions to prevent

entry of impurities.

H

Mark the hoses to avoid exchanging them during

re-installation.

8 - Slide the arm cylinder and bucket hoses off the boom,

leaving in position the hoses of the optional equip-

ment.

30-74

REMOVAL AND INSTALLATION

UPPER WORKING EQUIPMENT

PC12R-8 PC15R-8

RKPA1291

2

1

RKPA1271

1

3

RKPA1281

4

A

RKPA1520

5

5

Summary of Contents for PC12R-8 MISTRAL

Page 1: ......

Page 2: ...40 28 PC15R 8 ...

Page 4: ...00 2 PC12R 8 PC15R 8 ...

Page 17: ...GROUP 10 ...

Page 18: ...40 28 PC15R 8 ...

Page 30: ...10 12 PC12R 8 PC15R 8 PAGE INTENTIONALLY LEFT BLANK ...

Page 32: ...10 14 PC12R 8 PC15R 8 PAGE INTENTIONALLY LEFT BLANK ...

Page 34: ...10 16 PC12R 8 PC15R 8 PAGE INTENTIONALLY LEFT BLANK ...

Page 36: ...10 18 PC12R 8 PC15R 8 PAGE INTENTIONALLY LEFT BLANK ...

Page 38: ...10 20 PC12R 8 PC15R 8 PAGE INTENTIONALLY LEFT BLANK ...

Page 40: ...10 22 PC12R 8 PC15R 8 PAGE INTENTIONALLY LEFT BLANK ...

Page 42: ...10 24 PC12R 8 PC15R 8 PAGE INTENTIONALLY LEFT BLANK ...

Page 44: ...10 26 PC12R 8 PC15R 8 PAGE INTENTIONALLY LEFT BLANK ...

Page 79: ...10 61 PC12R 8 PC15R 8 PAGE INTENTIONALLY LEFT BLANK ...

Page 130: ...10 112 PC12R 8 PC15R 8 PAGE INTENTIONALLY LEFT BLANK ...

Page 132: ......

Page 133: ...GROUP 20 ...

Page 134: ...40 28 PC15R 8 ...

Page 158: ...20 24 PC12R 8 PC15R 8 PAGE INTENTIONALLY LEFT BLANK ...

Page 198: ......

Page 199: ...GROUP 30 ...

Page 200: ...40 28 PC15R 8 ...

Page 283: ...GROUP 40 ...

Page 284: ...40 28 PC15R 8 ...

Page 317: ...40 33 PC12R 8 PC15R 8 PAGE INTENTIONALLY LEFT BLANK ...

Page 324: ......