PRECAUTIONS TO BE TAKEN DURING MAINTENANCE

44

2.8.3 PERSONNEL

q

Only authorized and duly trained personnel can service and repair the machine; additional precautions must be

taken when grinding, welding and using a sledge hammer or heavy hammers.

q

When assemblying the equipment or cylinder connection pins, use wooden, plastic or in any case not excessi-

vely hard tools to check the centering of the holes.

Do not use your fingers, since you run the risk of cutting them.

2.8.4 EQUIPMENT

q

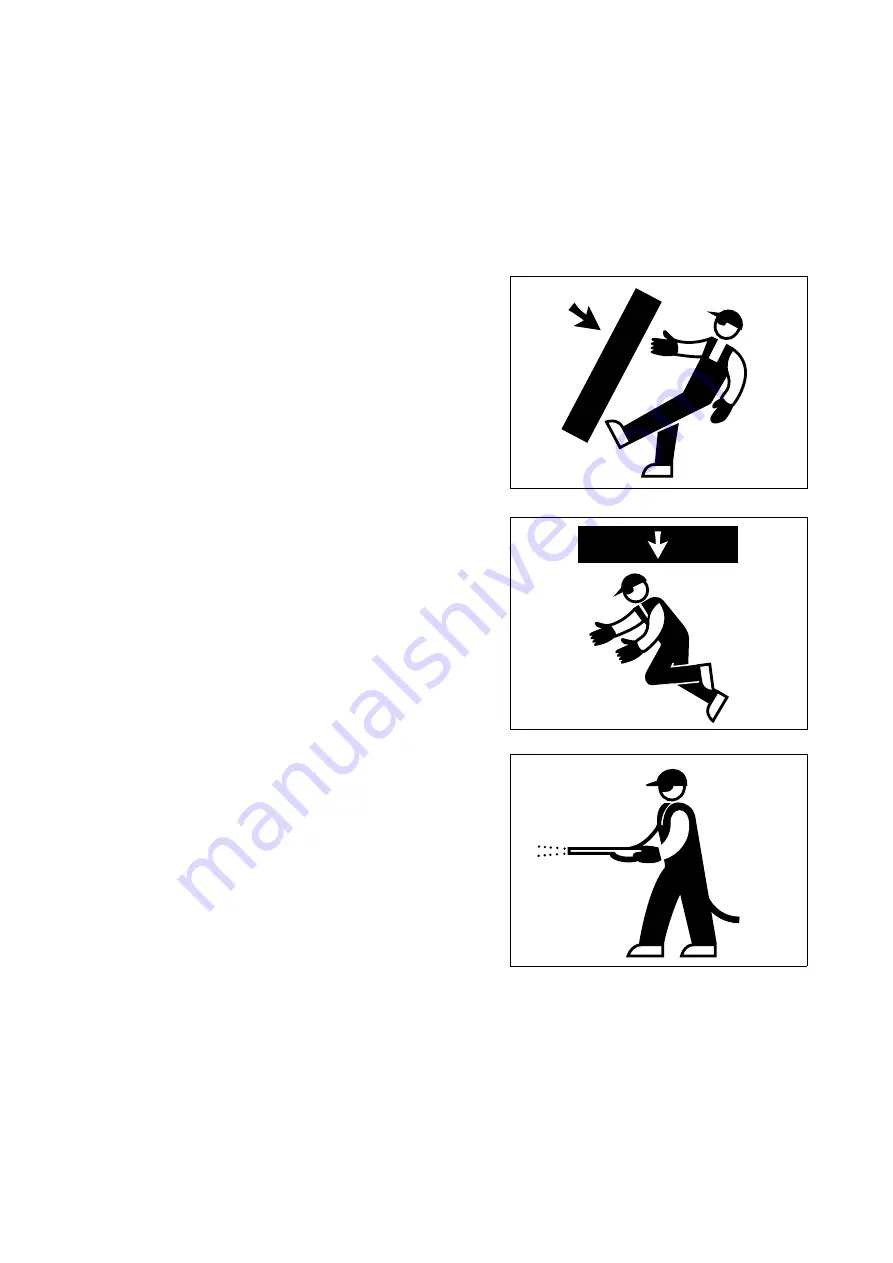

The normal or special equipment that must be installed on

the machine or that have been removed must be stored in

safe places, preventing them from falling down. If they fall on

someone, they can cause serious bodily harm.

q

When assemblying or removing any equipment, make sure

that the cables and the lifting hook are in good conditions

and properly dimensioned for the load to be lifted.

2.8.5 WORKING UNDER THE MACHINE

q

Always lower the work equipment to the ground or in any ca-

se to its lowest position before performing service or repairs

under the machine.

q

Always lock the machine wheels securely.

q

Do not work under the machine, if this is not sufficiently sup-

ported.

2.8.6 KEEPING THE MACHINE CLEAN

q

Spilled oil or grease, scattered tools or broken pieces are

dangerous, because they may cause someone to slip or trip.

Always keep the machine and the work site clean and tidy.

q

To clean the machine, use a pressurized jet of warm water or

steam and the appropriate detergents available on the

market. Do not use diesel oil, oil or solvents, since the for-

mer leave an oily coat that favours the sticking of dust, while

the latter (even if weak) damage the painted surfaces and

therefore facilitate rusting.

q

While cleaning the machine, keep the pressurized jet at a

minimum distance of approximately 60 cm, in order to avoid

damaging the warning plates and the pictograms.

If one or more plates should be damaged, request for spare

ones to Komatsu or to your Komatsu Dealer and provide for

replacing them.

q

Water into the electrical system provokes the oxidation of

the contacts and may hinder the start of the machine or even

make it start suddenly and abruptly. For this reason, never

use water or steam jets to clean sensors, connectors or the

inside of the operator's cab.

RWA01320

RWA02520

RWA01330

Summary of Contents for 37BF50111

Page 2: ......

Page 17: ...SAFETY AND ACCIDENT PREVENTION 15...

Page 19: ...SAFETY NOISE AND VIBRATION PLATES 17 RWA00010 RWA37020...

Page 21: ...SAFETY NOISE AND VIBRATION PLATES 19 RWA37040 RWA00010 RWA00020...

Page 53: ...THE MACHINE AND ITS OPERATIONS 51...

Page 62: ...GENERAL VIEWS 60 10 Left console switches 11 Right console switches RWAA9720 11 RWAA11260 10...

Page 154: ...152 PAGE INTENTIONALLY LEFT BLANK...

Page 155: ...MAINTENANCE 153...

Page 205: ...TECHNICAL SPECIFICATIONS 203...

Page 213: ...TECHNICAL DATA 211 SOLID TYRES SIZE MAKE 10x16 5 AIR BOSS...

Page 214: ...212 PAGE INTENTIONALLY LEFT BLANK...

Page 215: ...AUTHORISED OPTIONAL EQUIPMENT 213...

Page 242: ...240 PAGE INTENTIONALLY LEFT BLANK...

Page 243: ......

Page 244: ...2004 KOMATSU UTILITY EUROPE S p A All Rights Reserved Printed in Europe...