PRECAUTIONS TO BE TAKEN DURING MAINTENANCE

48

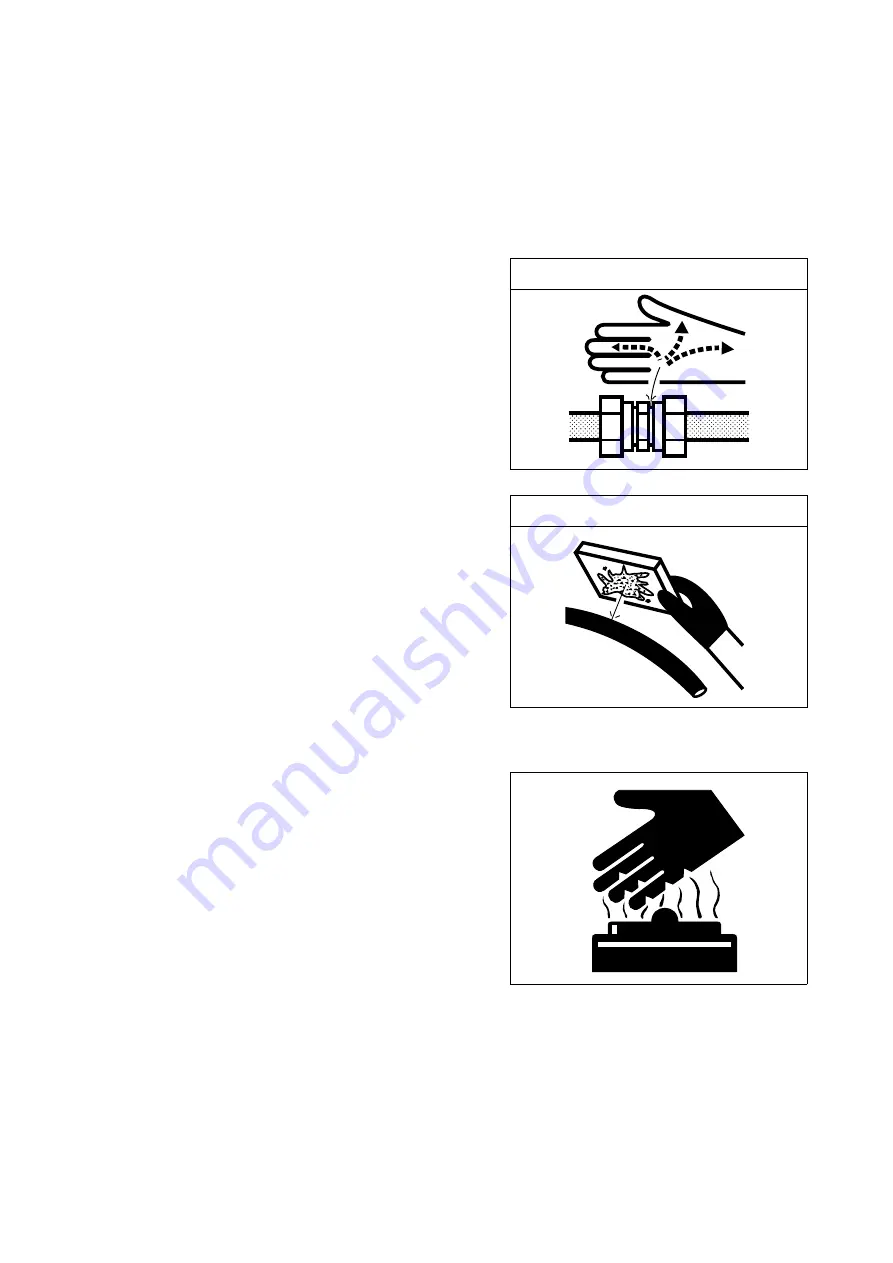

2.8.15 PRECAUTIONS CONCERNING HIGH-PRESSURE HOSES

q

Do not bend high-pressure hoses or rub them with sharp or abrasive objects.

Do not use bent or cracked rigid tubes or hoses that were previously rejected because of leaks or fastening de-

fects, since they may burst during use.

q

Always repair or replace any loose or faulty fuel or oil pipe. Any leakage of fuel or oil may cause fires.

2.8.16 PRECAUTIONS TO BE TAKEN

WHEN WORKING ON HIGH-PRES-

SURE SYSTEMS

q

Do not forget that the work equipment circuits are always un-

der pressure; for this reason, when it is necessary to add or

drain hydraulic oil, or service or inspect the hydraulic circuit,

it is advisable to lower the equipment to the ground and

completely release the pressures and the residual pressure

present in the tank.

Small leakages from pipes under pressure and the resulting

jets are extremely dangerous, since they can perforate the

skin and penetrate in the blood circulation or injure the eyes.

For this reason, always wear goggles and thick gloves du-

ring the inspections and use a piece of cardboard or a sheet

of plywood to check for oil leakages.

If you are struck by a jet of high-pressure oil or are injured,

even if slightly, consult a doctor immediately.

2.8.17 PRECAUTIONS FOR MAINTE-

NANCE WORK INVOLVING HIGH

TEMPERATURES AND PRES-

SURES

q

When the machine is stopped at the end of work, the engine

coolant, the oil and all the components are hot and the

hydralic circuits are under pressure.

In these conditions, if the coolant, the hydraulic oil and the

engine oil are to be drained in order to change them or the

filters, there are serious risks of injuries and burns.

Wait for the temperature to lower within the normal operating

range (40-45ºC) before carrying out the maintenance opera-

tions in accordance with the procedures indicated in the rele-

vant sections of this manual.

RWA01480

DANGEROUS!

RWA01580

CORRECT

RWA00990

Summary of Contents for 37BF50111

Page 2: ......

Page 17: ...SAFETY AND ACCIDENT PREVENTION 15...

Page 19: ...SAFETY NOISE AND VIBRATION PLATES 17 RWA00010 RWA37020...

Page 21: ...SAFETY NOISE AND VIBRATION PLATES 19 RWA37040 RWA00010 RWA00020...

Page 53: ...THE MACHINE AND ITS OPERATIONS 51...

Page 62: ...GENERAL VIEWS 60 10 Left console switches 11 Right console switches RWAA9720 11 RWAA11260 10...

Page 154: ...152 PAGE INTENTIONALLY LEFT BLANK...

Page 155: ...MAINTENANCE 153...

Page 205: ...TECHNICAL SPECIFICATIONS 203...

Page 213: ...TECHNICAL DATA 211 SOLID TYRES SIZE MAKE 10x16 5 AIR BOSS...

Page 214: ...212 PAGE INTENTIONALLY LEFT BLANK...

Page 215: ...AUTHORISED OPTIONAL EQUIPMENT 213...

Page 242: ...240 PAGE INTENTIONALLY LEFT BLANK...

Page 243: ......

Page 244: ...2004 KOMATSU UTILITY EUROPE S p A All Rights Reserved Printed in Europe...