FOREWORD

CONNECTING PUSH-PULL TYPE COUPLER

00-16

d

WB142-5

CONNECTING PUSH-PULL TYPE COUPLER

00

★

Type 1

1.

Disconnection

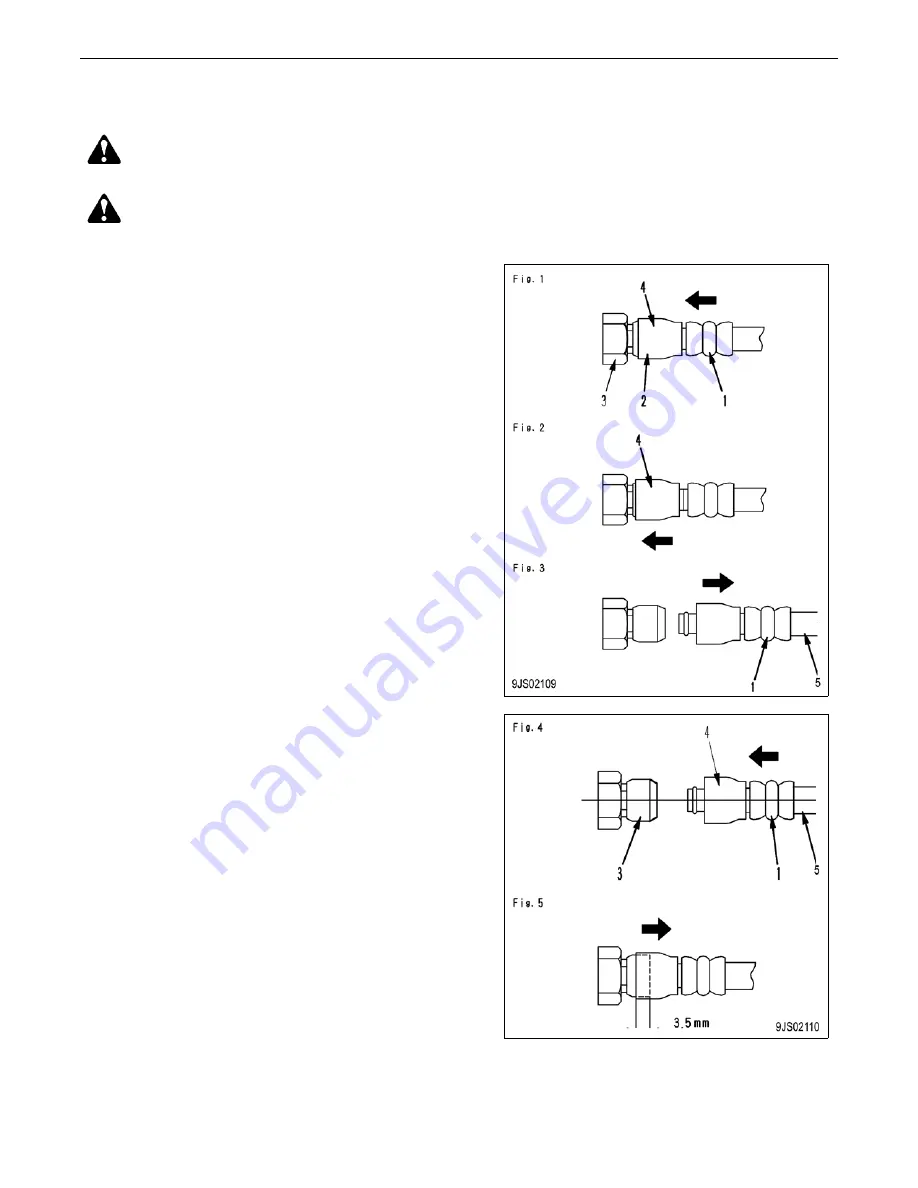

A. Hold adapter (1) and push hose joint (2) into mating

adapter (3) (Fig. 1).

•

The adapter can be pushed in about 3.5 mm (0.14

in).

•

Do not hold rubber cap portion (4).

B. After hose joint (2) is pushed into adapter (3), press rub-

ber cap portion (4) against adapter (3) until it clicks (Fig.

2).

C. Hold hose adapter (1) or hose (5) and pull it out (Fig. 3).

•

Since some hydraulic oil flows out, prepare a con-

tainer to catch oil.

2.

Connection

A. Hold hose adapter (1) or hose (5) and insert it in mating

adapter (3), aligning them with each other (Fig. 4).

•

Do not hold rubber cap portion (4).

B. After inserting the hose in the mating adapter perfectly,

pull it back to check its connecting condition (Fig. 5).

•

When the hose is pulled back, the rubber cap por-

tion moves toward the hose about 3.5 mm (0.14 in).

This does not indicate an abnormality, however.

WARNING!

Before carrying out the following work, loosen the oil filler cap of the hydraulic tank grad-

ually to release the residual pressure from the hydraulic tank.

WARNING!

Even if the residual pressure is released from the hydraulic tank, some hydraulic oil flows

out when the hose is disconnected. Accordingly, prepare a container to catch oil.