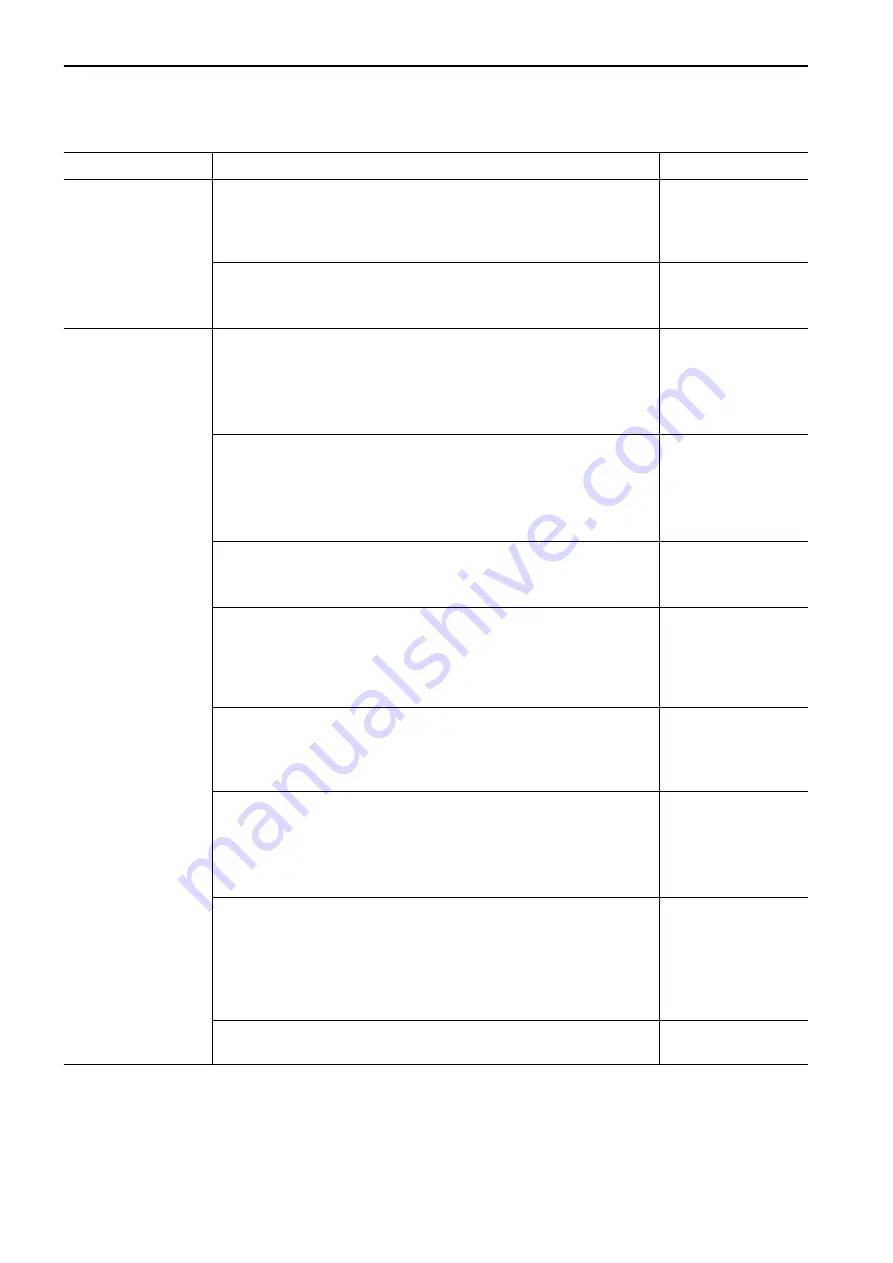

WORKING ACCURACY

Phenomena

Check item

Reference

The value varies

largely when check-

ing or adjusting the

accuracy of bucket

edge.

Reciprocate each cylinder by 1 round trip to place it to both stroke

ends.

Detection of cylinder stroke may have an error, reset the detection by

placing it to the stroke end.

-

Check that the IMU adjustment is normal.

If the adjustment is necessary, perform the adjustment execute, and

then check the accuracy of bucket edge again.

IMU ADJUSTMENT

Finishing accuracy is

poor.

•

Average eleva-

tion of finished

face is deeper

than the design

data or does not

reach the de-

sign data.

•

The finished

surface is rip-

pled.

Check that the error message of “Initializing...”, etc. is displayed on

the screen of control box.

The accuracy of bucket edge is deteriorated if an error message is

displayed.

Wait for the message to be cleared, and then start the work.

PHENOMENA AND

ACTIONS FOR CON-

TROL BOX

Check that the coordinates of bucket edge position changes largely.

The changes of bucket edge behavior may occur irregularly due to

the fluctuation of GNSS antenna position.

If the things are not improved after waiting a while, acquire the satel-

lite again.

BUCKET EDGE PO-

SITION

METHOD FOR RE-

SETTING CONNEC-

TION

Check that there is no defect such as hole or protrusion exists on the

design data.

If there is any defect, semi-auto mode may not operate normally.

-

Check that the machine is on the stable ground so that it is not shak-

en.

Depending on the response of IMU sensor which detects the ma-

chine posture, if the machine rocks largely, machine may dig in the

design data, but it is not a trouble.

PRECAUTIONS FOR

REPLACING PARTS

AND FAILURES

Check that the IMU adjustment is normal.

If the adjustment is necessary, perform the "Adjustment Execute",

and then check again that the facing angle compass is normally dis-

played.

IMU ADJUSTMENT

Check that the bucket weight setting is complied with the actual

bucket installed.

The accuracy of construction may decrease if the bucket weight set-

ting is not correct.

Change the setting to be appropriate with the bucket weight setting.

BUCKET WEIGHT

SETTING

Check that the boom fine control adjustment is completed.

When the bucket weight setting is changed, the starting movement of

the work equipment becomes unstable, so does the machine behav-

ior.

Perform the Boom Fine Control Adjustment always when the bucket

weight setting is changed.

BOOM FINE CON-

TROL ADJUSTMENT

Check the stop control adjustment.

SEMI-AUTO AD-

JUSTMENT

TROUBLESHOOTING

EXECUTIONS

8-60

Summary of Contents for A31001

Page 12: ...LOCATION OF SAFETY LABELS Options are shown with marks in the figure SAFETY LABELS SAFETY 2 4...

Page 106: ......

Page 107: ...SPECIFICATIONS 5 1...

Page 110: ......

Page 116: ......

Page 117: ...SETTING 7 1...

Page 311: ...EXECUTIONS 8 1...

Page 376: ...PC360LCi 11 PC390LCi 11 HYDRAULIC EXCAVATOR Form No CEAM032703...