If there is any problem, the related parts must be replaced. Ask your Komatsu distributor for replacement.

EVERY 4500 HOURS MAINTENANCE

Maintenance for every 250 and 500 hours services should be performed out at the same time.

METHOD FOR CLEANING KDPF

Contact your Komatsu distributor for cleaning of the KDPF.

METHOD FOR CLEANING DEF TANK

Ask your Komatsu distributor for cleaning of the DEF tank.

METHOD FOR CLEANING FUEL DOSER

For cleaning the fuel doser, ask your Komatsu distributor.

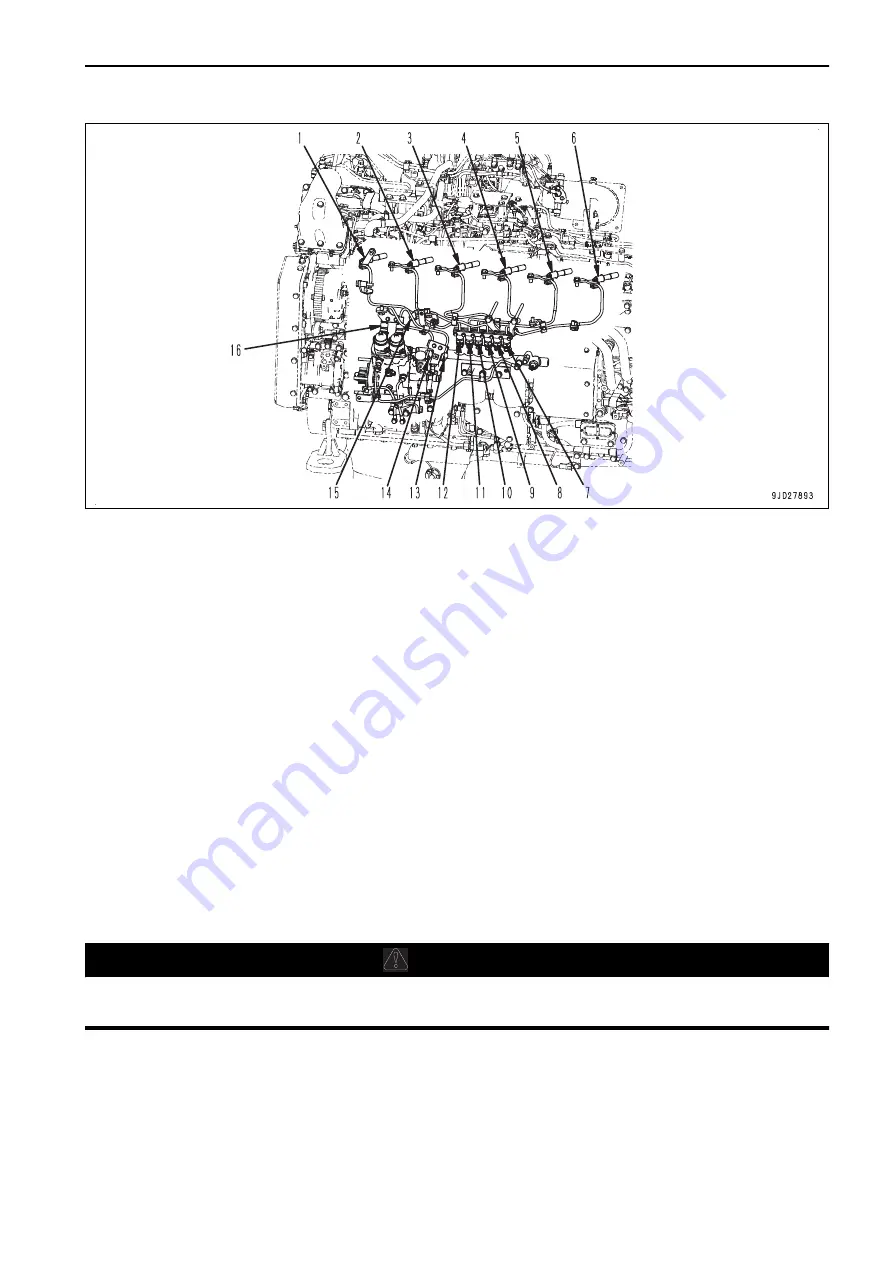

METHOD FOR CHECKING FOR MISSING FUEL SPRAY PREVENTION CAP ON

FUEL DOSER PIPING, HARDENING OF RUBBER

The fuel spray prevention cap acts to prevent the fuel from coming into contact with high-temperature parts of

the engine and causing a fire if the fuel should leak or spray out.

Check visually and touch by hand to check that there are no missing caps, loose bolts or hardening of the rub-

ber.

If there are any problems, the parts must be replaced. Ask your Komatsu distributor for replacement.

METHOD FOR CHECKING EXHAUST PIPE FIRE PREVENTION COVER

k

k

WARNING

Immediately after the engine is stopped, all the parts are still very hot, and may cause burn injury.

Wait for the temperature to go down, and then start the work.

Exhaust pipe fire prevention covers (3) and (6) may suffer from material deterioration or damage depending on

the conditions of use and the operating environment of the machine.

1.

Open the engine hood.

MAINTENANCE

MAINTENANCE PROCEDURE

4-81

Summary of Contents for HD325-8

Page 2: ......

Page 13: ...FOREWORD INTRODUCTION 1 11 ...

Page 25: ...LOCATION OF SAFETY LABELS SAFETY SAFETY LABELS 2 3 ...

Page 26: ...SAFETY LABELS SAFETY 2 4 ...

Page 340: ......

Page 424: ......

Page 425: ...SPECIFICATIONS 5 1 ...

Page 429: ...ATTACHMENTS AND OP TIONS Before reading this chapter read and understand the SAFETY 6 1 ...

Page 447: ...REPLACEMENT PARTS 7 1 ...

Page 463: ......