.

ATTACHMENTS, OPTIONS

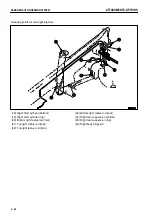

HANDLING AUTO-GREASING SYSTEM

SETTING GREASE CAN

NOTICE

Check that there is no dent in the can. If there is a dent, the follower plate will not go down to the bottom and it will be impossible

to carry out greasing.

This brings the danger of damage caused by insufficient greasing of the machine.

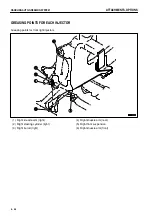

1. Release 4 latches (2) of grease pump (1), and open the top of

the grease pump.

2. Insert grease can (4) into case (3) of the grease pump.

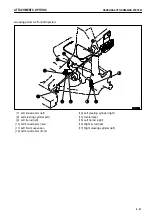

The applicable follower plate differs according to whether the grease can is used or not. Use the appropriate part

No. follower plate.

Follower plate part No.

When using grease can

427-S95-2510

When not using grease can

427-S95-2520

REMARK

Follower plate 427-S95-2510 is applicable for cans with an inside diameter from 275 mm to 290 mm.

3. Insert the pump tube at the top of the grease pump into the grease, then set follower plate (5) inside grease can

(4).

4. Check that there is no leakage of grease from between grease can (4) and follower plate (5).

5. Secure with latches (2) at the top of grease pump (1).

6 - 46

Summary of Contents for HD785-5

Page 2: ... 1 1 ...

Page 4: ... FOREWORD FOREWORD 1 3 ...

Page 5: ... FOREWORD FOREWORD 1 4 ...

Page 15: ... 2 1 ...

Page 19: ... SAFETY SAFETY LABELS POSITION FOR ATTACHING SAFETY LABELS 2 5 ...

Page 47: ... 3 1 ...

Page 132: ... OPERATION OPERATION Brake performance Downhill distace Continuous Tire size 27 00R49 3 86 ...

Page 166: ... 4 1 ...

Page 237: ... 5 1 ...

Page 239: ... SPECIFICATIONS SPECIFICATIONS 5 3 ...

Page 240: ... 6 1 ...

Page 299: ... 7 1 ...