MAINTENANCE PLAN

144

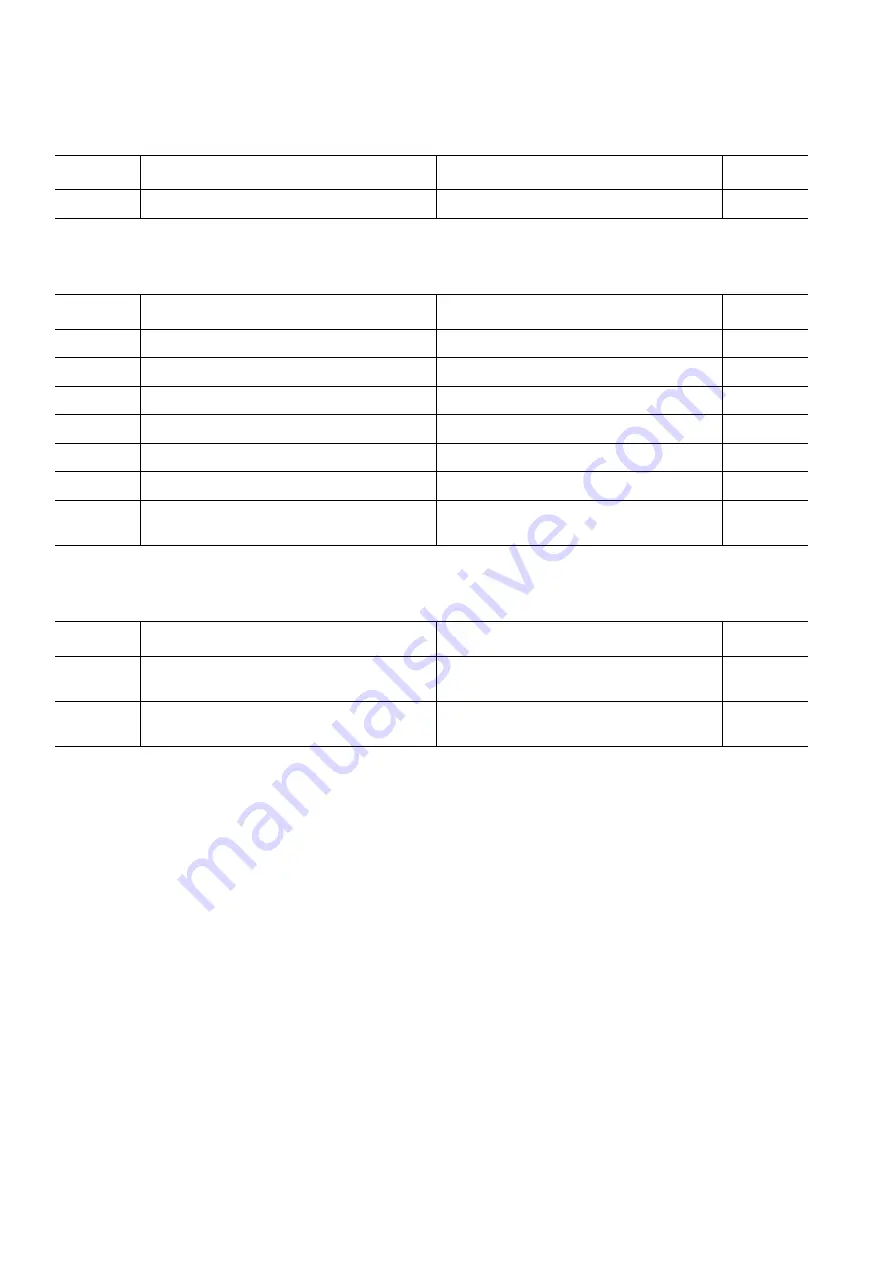

4.7.12 MAINTENANCE EVERY 1000 HOURS OF OPERATION

4.7.13 MAINTENANCE EVERY 2000 HOURS OF OPERATION

4.7.14 MAINTENANCE EVERY 4000 HOURS OF OPERATION

N.

PART

OPERATION

PAGE

a

Engine valves

Check clearance

178

N.

PART

OPERATION

PAGE

a

Travel reduction gears

Change oil

179

b

Swing reduction gear

Change oil

180

c

Hydraulic oil and suction filter

Change oil and clean filter

181

d

Coolant

Change

184

e

Ball-bearing ring pinion

Change lubricant

185

f

Alternator and starter

Check

185

g

A/C system cooling gas

(only for machines with air conditioner)

Check quantity

186

N.

PART

OPERATION

PAGE

a

A/C system filter (dehydrator filter)

(only for machines with air conditioner)

Change

187

b

A/C system compressor

(only for machines with air conditioner)

Check

187

Summary of Contents for PC110R-1

Page 2: ......

Page 19: ...17 SAFETY AND ACCIDENT PREVENTION...

Page 51: ...49 THE MACHINE AND ITS OPERATIONS...

Page 126: ...124 PAGE INTENTIONALLY LEFT BLANK...

Page 127: ...125 MAINTENANCE...

Page 190: ...188 PAGE INTENTIONALLY LEFT BLANK...

Page 191: ...189 TECHNICAL SPECIFICATIONS...

Page 198: ...196 PAGE INTENTIONALLY LEFT BLANK...

Page 199: ...197 AUTHORISED OPTIONAL EQUIPMENT...