MAINTENANCE PLAN

168

4.7.10 MAINTENANCE AFTER THE FIRST 500 HOURS OF OPERATION

(Only for machines in which the synthetic biodegradable oil type

HEES is used)

4.7.11 MAINTENANCE EVERY 500 HOURS OF OPERATION

4.7.11.a CHANGING THE HYDRAULIC SYSTEM

OIL FILTER

The following maintenance operation must be carried out after the first 500 hours of operation, together with the

maintenance operations to be carried out “EVERY 500 HOURS”.

•

HYDRAULIC OIL CHANGE AND SUCTION FILTER CLEANING

For further details on the various maintenance operations, see section “EVERY 2000 HOURS”.

These operations must be carried out together with those to be carried out EVERY 50, 100 and 250 HOURS.

DANGER

•

Soon after the machine has been stopped the hydraulic oil

is very hot; let it cool down until it reaches a temperature of

40-45°C before changing it.

•

The hydraulic system is pressurized; loosen the filling cap

slowly to release the residual pressure.

•

Oils, filters, coolants and batteries are considered special

waste and must be collected and disposed of according to

the anti-pollution regulations in force.

CAUTION

•

On new machines, change the hydraulic oil filter cartridge

after the first 250 hours of operation and successively eve-

ry 500 hours.

•

On machines in which the synthetic biodegradable oil type

HEES is used, the first change must be carried out after the

first 50 hours of operations and the successive ones every

500 hours.

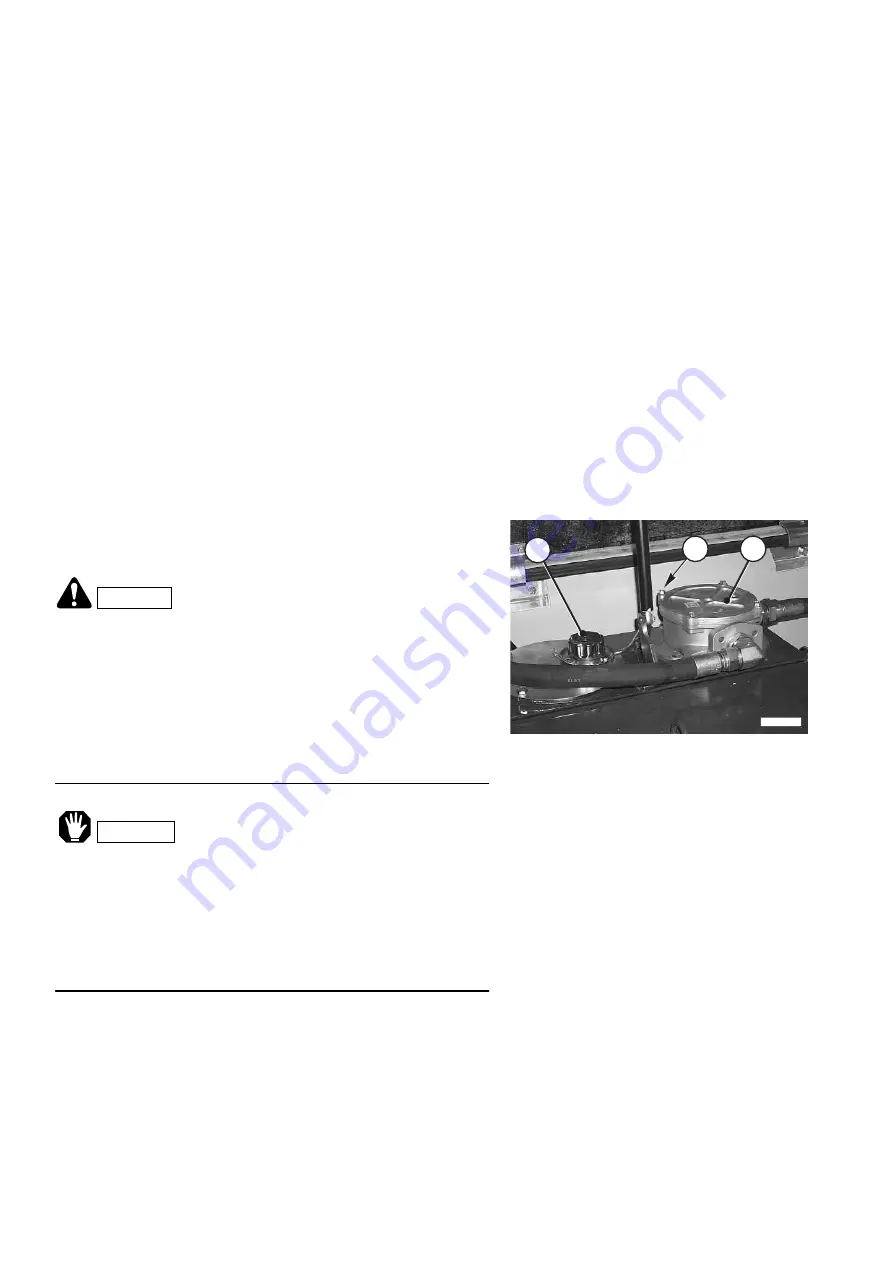

The filter is positioned on the hydraulic system drain outlet and

blocks the metal particles that come off the various components

due to their wear. The filter can be reached by opening the right

side cover (see “3.5.2 SIDE COVER”); to change it, proceed as

follows:

1 - Slowly loosen the filling cap (1) in order to release the residual

pressure from the tank and then remove it.

RWAA5530

1

2

3

Summary of Contents for PC110R-1

Page 2: ......

Page 19: ...17 SAFETY AND ACCIDENT PREVENTION...

Page 51: ...49 THE MACHINE AND ITS OPERATIONS...

Page 126: ...124 PAGE INTENTIONALLY LEFT BLANK...

Page 127: ...125 MAINTENANCE...

Page 190: ...188 PAGE INTENTIONALLY LEFT BLANK...

Page 191: ...189 TECHNICAL SPECIFICATIONS...

Page 198: ...196 PAGE INTENTIONALLY LEFT BLANK...

Page 199: ...197 AUTHORISED OPTIONAL EQUIPMENT...