MAINTENANCE PLAN

181

4.7.13.c CHANGING THE HYDRAULIC SYSTEM OIL

AND CLEANING THE SUCTION FILTER

CAUTION

•

On machines containing synthetic biodegradable hydraulic

oil type HEES, carry out the change after the first 500 hours

of operation and successively every 2000 hours, and in any

case at least once a year.

DANGER

•

Retract the bucket and arm cylinder completely, extend the

cylinders of the two-piece boom completely, lower the

bucket teeth to the ground and, after stopping the engine,

release the residual pressures from the work equipment

circuits (by operating the controls more than once) and

from the tank (by slowly loosening the filling cap).

•

Let the oil cool down until it reaches 40-45°C before carry-

ing out any maintenance operation.

•

Immediately clean any area dirty with oil.

•

Oils, filters, coolants and batteries are considered special

waste and must be collected and disposed of according to

the anti-pollution regulations in force.

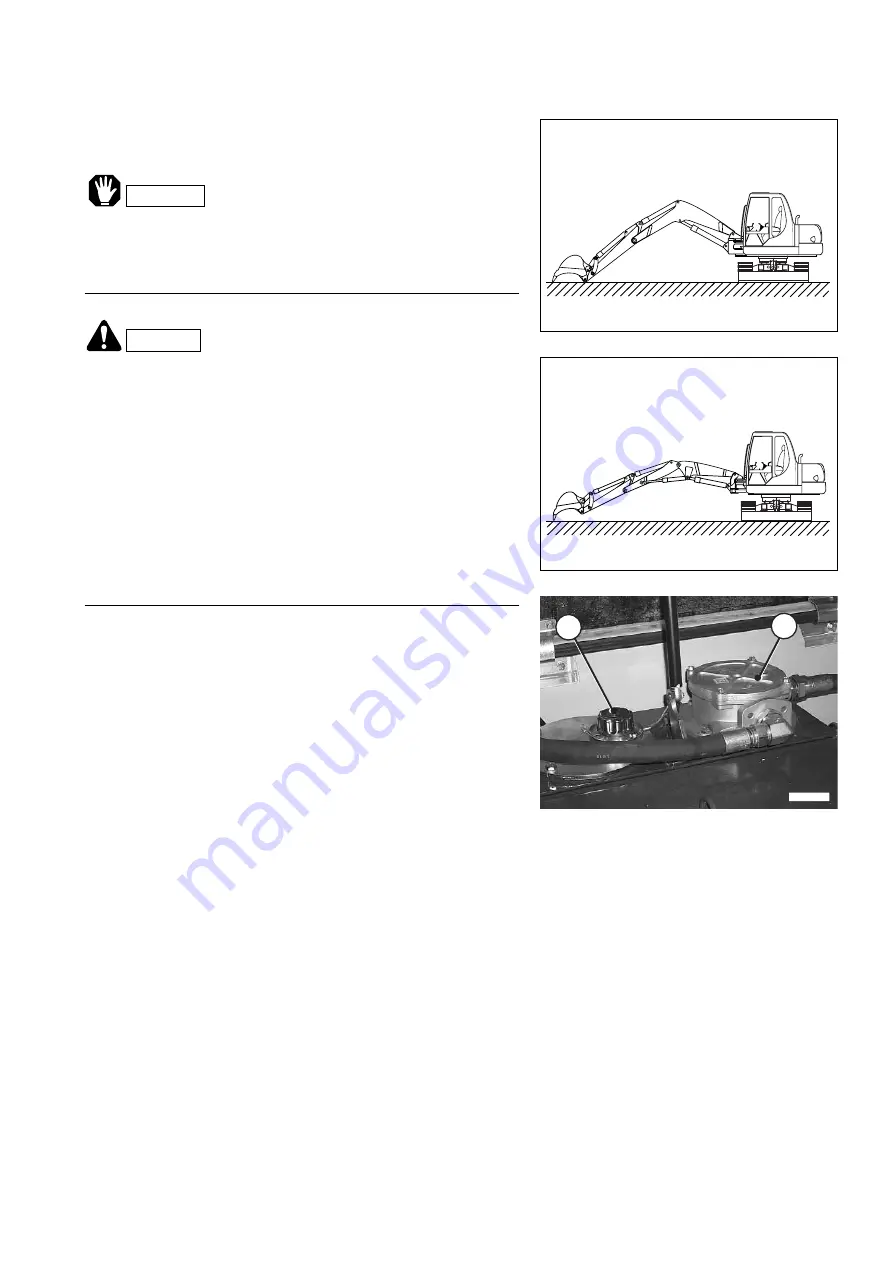

1 - Rotate the upper structure by 90°, in such a way as to leave

the lower part of the hydraulic oil tank free from the tracks.

2 - Retract the bucket and arm cylinder completely, extend the cyl-

inders of the two-piece boom completely, lower the boom until

the bucket teeth touch the ground.

3 - Lower the blade to the ground.

4 - Stop the engine and release the residual pressures from the

equipment circuits by shifting the controls more than once.

5 - Open the right side cover (see “3.5.2 SIDE COVER”) and

slowly loosen the filling cap (1) to release the residual pres-

sure.

RYA15890

RWAA5610

1

3

RYA15900

Summary of Contents for PC110R-1

Page 2: ......

Page 19: ...17 SAFETY AND ACCIDENT PREVENTION...

Page 51: ...49 THE MACHINE AND ITS OPERATIONS...

Page 126: ...124 PAGE INTENTIONALLY LEFT BLANK...

Page 127: ...125 MAINTENANCE...

Page 190: ...188 PAGE INTENTIONALLY LEFT BLANK...

Page 191: ...189 TECHNICAL SPECIFICATIONS...

Page 198: ...196 PAGE INTENTIONALLY LEFT BLANK...

Page 199: ...197 AUTHORISED OPTIONAL EQUIPMENT...