MAINTENANCE PLAN

179

4.7.13 MAINTENANCE EVERY 2000 HOURS OF OPERATION

4.7.13.a CHANGING THE OIL IN THE TRAVEL REDUCTION GEARS

Carry out these operations together with those to be performed EVERY 50, 100, 250, 500 and 1000 HOURS.

DANGER

•

Soon after the machine has been stopped the oil is very hot; let the oil cool down until it reaches a tem-

perature of 40-45°C before changing it.

•

Oils, filters, coolants and batteries are considered special waste and must be collected and disposed of

according to the anti-pollution regulations in force.

CAUTION

•

On new machines, change the travel reduction gear oil af-

ter the first 250 hours of operation and successively every

2000 hours.

This operation must be carried out with the machine on level

ground at a temperature of 40-45°C, so that the oil is more fluid

and can be drained easily together with the suspended solid parti-

cles.

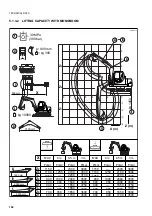

1 - Move the machine until the drain plug (1) is on the vertical axis

in low position.

2 - Remove the drain plug (1) and let all the used oil flow into a

container with suitable capacity.

While the oil flows out, remove the level plug (2).

Use a 8 mm hexagon spanner.

3 - After draining the oil, put back the plug (1) and pour new oil of

the recommended type through the hole (2) until reaching the

lower edge of the hole itself.

4 - Put back the plug (2).

Carry out some movements, stop the machine and check the lev-

els again.

Use only the prescribed oil.

(See “4.3 FUEL, COOLANT AND LUBRICANTS”).

RWA19650

1

2

Summary of Contents for PC110R-1

Page 2: ......

Page 19: ...17 SAFETY AND ACCIDENT PREVENTION...

Page 51: ...49 THE MACHINE AND ITS OPERATIONS...

Page 126: ...124 PAGE INTENTIONALLY LEFT BLANK...

Page 127: ...125 MAINTENANCE...

Page 190: ...188 PAGE INTENTIONALLY LEFT BLANK...

Page 191: ...189 TECHNICAL SPECIFICATIONS...

Page 198: ...196 PAGE INTENTIONALLY LEFT BLANK...

Page 199: ...197 AUTHORISED OPTIONAL EQUIPMENT...