CLAMSHELL BUCKET

210

6.3.3 MAINTENANCE

RWA19910

6

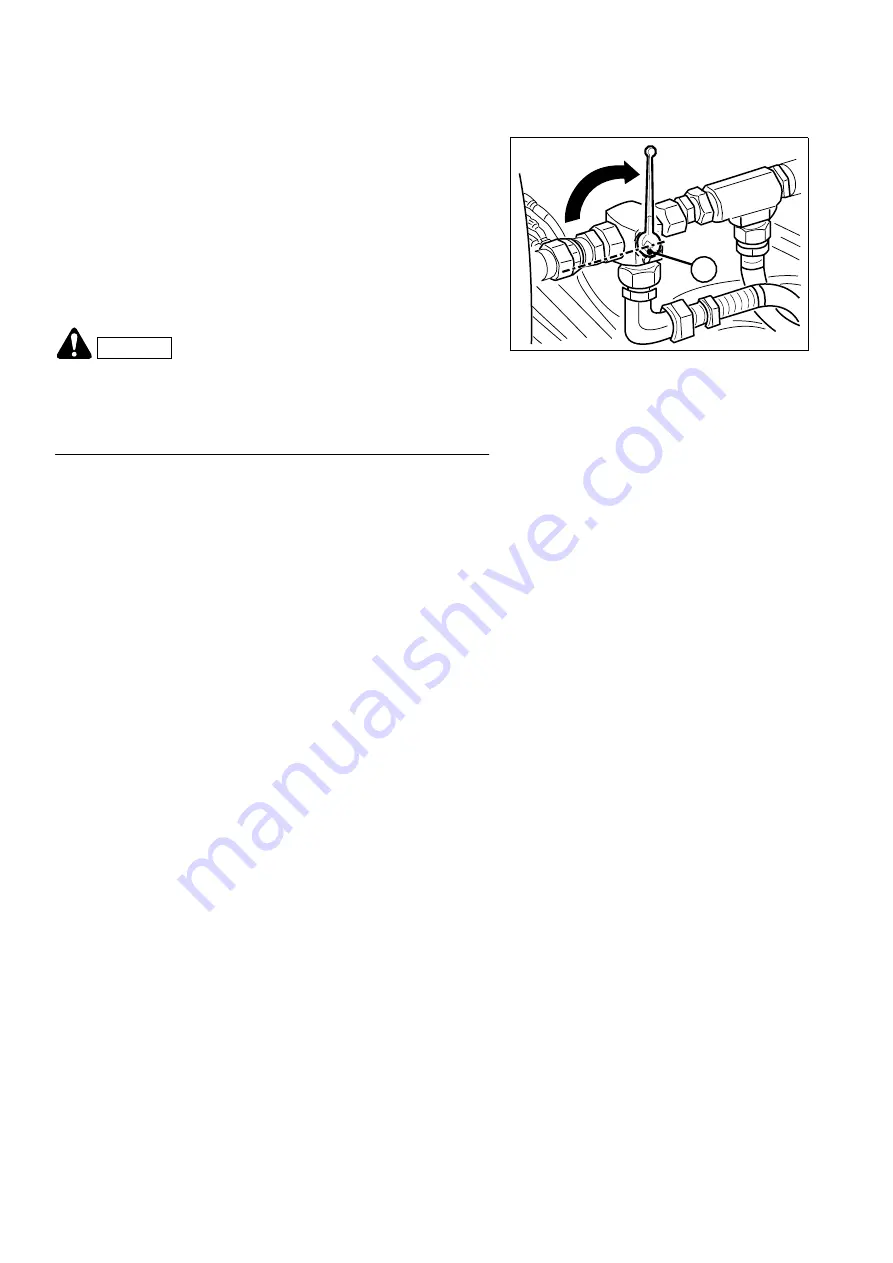

11 - Rotate the lever of the selection valve (6) completely clock-

wise.

12 - Lubricate the arm connection joints (see “4.7.4.a LUBRICAT-

ING THE JOINTS”) and the clamshell bucket (see the specif-

ic use and maintenance manual).

13 - Start the machine and lift the clamshell bucket of a few centi-

metres.

14 - Open, curl and swing the bucket slowly more than once to

check the tightness of the circuits.

DANGER

•

Always wear thick gloves and safety goggles during this

check.

•

To check the system for leaks, use a piece of cardboard or

a wooden board.

The hydraulic system does not require any maintenance opera-

tion and inspection other than those prescribed for the machine.

For the maintenance operations required for the equipment, see

the specific manuals.

Summary of Contents for PC110R-1

Page 2: ......

Page 19: ...17 SAFETY AND ACCIDENT PREVENTION...

Page 51: ...49 THE MACHINE AND ITS OPERATIONS...

Page 126: ...124 PAGE INTENTIONALLY LEFT BLANK...

Page 127: ...125 MAINTENANCE...

Page 190: ...188 PAGE INTENTIONALLY LEFT BLANK...

Page 191: ...189 TECHNICAL SPECIFICATIONS...

Page 198: ...196 PAGE INTENTIONALLY LEFT BLANK...

Page 199: ...197 AUTHORISED OPTIONAL EQUIPMENT...