120

GUIDE TO MAINTENANCE

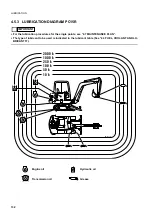

4.1

GUIDE TO MAINTENANCE

•

Before opening the engine hood, engage all the safety locks and stop the engine.

•

If it is necessary to check the oil level in the hydraulic tank, retract the bucket and arm cylinders completely and

lower the bucket teeth to the ground.

•

Carry out any operation on firm and level ground.

•

Use Komatsu Utility genuine oils and greases; choose oils suitable for the ambient temperature.

•

Use clean oils and greases. Keep the oil and grease containers clean. Keep any foreign matter away from oils

and greases.

•

Always keep the machine clean. This makes it easier to find out any part causing troubles.

In particular, keep the grease nipples, the breathers and the areas near the openings for the level checks clean

and prevent any impurities from getting into/on them.

•

Draining hot oil or coolant immediately after stopping the engine is hazardous. Wait for the engine to cool down

until reaching at least 40÷50° C.

•

When changing the oils or the filters, check if metal particles are present. If you find large quantities of metal

particles, contact your Komatsu Utility Dealer.

•

Check and change the oil in a clean place and prevent any impurities from getting into the tank.

•

Before carrying out any maintenance operation, hang the warning plates on the ignition switch, the control le-

vers and the cab door, if the machine is provided with cab, in order to prevent anyone from starting the engine

by mistake.

•

When performing maintenance operations, always take the precautions indicated on the safety plates applied

onto the machine.

•

Instructions for arc welding.

1 - Turn the ignition key to position « ».

2 - Disconnect the battery (first the negative pole and then the positive pole).

3 - Disconnect the alternator.

4 - Do not apply more than 200V continuously.

5 - Connect the earth cable within 1 m from the point in which the welding must be carried out.

6 - Avoid placing gaskets and bearings between the welding area and the earth cable.

•

Do not use flammable fluids to clean the machine parts. Keep naked flames or lit cigarettes away from these

fluids.

•

When O-rings and gaskets are removed, clean the sealing surfaces thoroughly and replace the O-rings and

gaskets with new ones. Fit the O-rings and gaskets correctly when reassembling.

•

Avoid keeping loose objects or tools in your pockets: they may fall out and drop into the machine, especially

when you open covers and work on the machine while bending over it.

•

When washing the machine, do not direct the high-pressure water jet onto the radiator and the heat exchanger.

•

When washing the machine, protect the electric system connectors and avoid wetting the ignition switch.

•

Before starting work in mud, under the rain, on seashores or river banks, carry out a general lubrication.

Wash the machine immediately after work to protect the components from rust. Lubricate the equipment joints

more frequently than usual.

•

When working at dusty work sites, proceed as follows:

1 - Check the air cleaner for any clogging and clean it more frequently than usual.

2 - Clean the radiator and the heat exchanger frequently, to avoid any clogging of the fins.

3 - Change the diesel oil filter more frequently than usual.

4 - Clean the electrical components, especially the starter and the alternator, to avoid any accumulation of dust.

Summary of Contents for PC12R-8

Page 2: ......

Page 12: ...10...

Page 20: ...18...

Page 21: ...SAFETY AND ACCIDENT PREVENTION...

Page 23: ...SAFETY NOISE AND VIBRATION PLATES 21 RWA05440...

Page 27: ...SAFETY NOISE AND VIBRATION PLATES 25 EMERGENCY EXIT LIFTING POINT RWA00190 RWA04920...

Page 55: ...THE MACHINE AND ITS OPERATIONS...

Page 88: ...86...

Page 120: ...118...

Page 121: ...MAINTENANCE...

Page 177: ...TECHNICAL SPECIFICATIONS...

Page 198: ...196...

Page 199: ...AUTHORISED OPTIONAL EQUIPMENT...