123

MAINTENANCE NOTES

4.2.1.3

FUEL

4.2.2 NOTES REGARDING THE HYDRAULIC SYSTEM

•

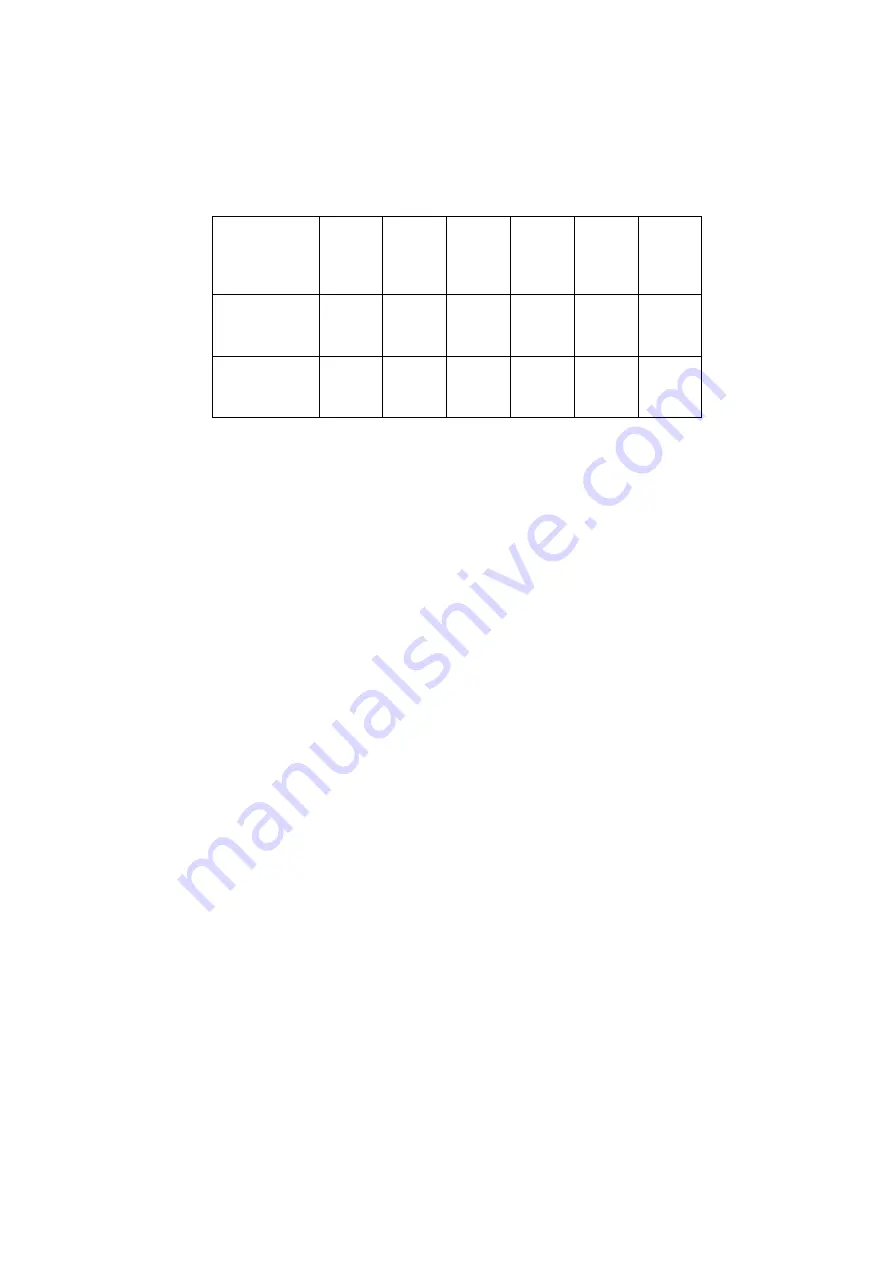

The quantity of antifreeze to be added to the coolant depends on the minimum temperatures in the place where

the machine is used.

Keep to the following reference table:

•

Use drinkable water and in any case soft water.

•

Do not use corrosion inhibitors containing soluble oil, since they damage the rubber couplings.

•

In case of doubt, contact your Komatsu Utility Dealer.

QUANTITY OF ANTIFREEZE TO BE ADDED TO THE WATER

Minimum

ambient

temperature

(°C)

-5

-10

-15

-20

-25

-30

Quantity

of antifreeze

(l)

0.8

1.0

1.15

1.3

1.45

1.6

Quantity

of water

(l)

2.4

2.2

2.05

1.9

1.75

1.6

•

Always use fuel suitable for the engine. Other fuels with different specifications may damage the engine or re-

duce its power.

•

Always refuel at the end of the work day.

•

When refuelling, make sure that there is no water on the fuel drum cover and take care not to draw the conden-

sate from the drum bottom.

•

If fuel runs out, or if the fuel filter has been replaced, it is necessary to bleed the circuit.

•

Be extremely careful when performing maintenance operations on the hydraulic system, since soon after work

the oil is very hot.

The circuit is pressurized not only during work, but also at the end of work.

•

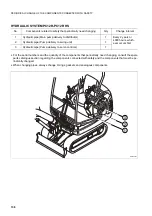

The maintenance operations required for the hydraulic system are the following:

1 - daily check of the oil level in the tank;

2 - periodical change of the oil filter;

3 - periodical change of the oil.

•

Always bleed the circuit after changing the oil filter or the oil.

•

When a component is removed from the circuit, check the gaskets and O-rings and change them if they are

damaged.

•

When a cylinder or a component of the hydraulic circuit is removed, after reassembly bleed the circuit by pro-

ceeding as follows:

1 - start the engine and let it idle;

2 - make all the cylinders perform 4÷5 movements, stopping them at approx. 100 mm from the end of their

stroke;

3 - slowly make all the cylinders reach the end of their stroke for 3÷4 times.

Summary of Contents for PC12R-8

Page 2: ......

Page 12: ...10...

Page 20: ...18...

Page 21: ...SAFETY AND ACCIDENT PREVENTION...

Page 23: ...SAFETY NOISE AND VIBRATION PLATES 21 RWA05440...

Page 27: ...SAFETY NOISE AND VIBRATION PLATES 25 EMERGENCY EXIT LIFTING POINT RWA00190 RWA04920...

Page 55: ...THE MACHINE AND ITS OPERATIONS...

Page 88: ...86...

Page 120: ...118...

Page 121: ...MAINTENANCE...

Page 177: ...TECHNICAL SPECIFICATIONS...

Page 198: ...196...

Page 199: ...AUTHORISED OPTIONAL EQUIPMENT...