134

PERIODICAL CHANGE OF THE COMPONENTS CONNECTED WITH SAFETY

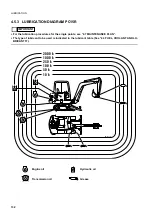

4.6 PERIODICAL CHANGE OF THE COMPONENTS CONNECT-

ED WITH SAFETY

To ensure safety at any moment while driving and using the machine, the operator must carry out all the periodic

maintenance operations prescribed. Furthermore, the operator must periodically change the components indicat-

ed in the table in the following page, which are especially related to safety and accident-prevention rules. These

components are subject to wear and since it is particularly difficult to evaluate their conditions through simple pe-

riodic maintenance, after a certain period it is advisable to change them independently of their state, in order to

keep them efficient over time. Repair or replace these components immediately in case of failures or anomalies,

even if the time interval prescribed for their change has not elapsed yet.

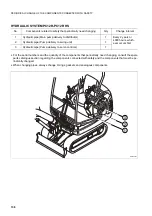

If the pipe clamps show signs of deterioration, like deformations or cracks, provide for changing them together

with the pipes.

In addition to the periodical change of the components listed in the following page, the inspections described

here below are to be carried out on the hydraulic pipes. In case of anomalies, carry out the necessary adjust-

ments and changes, or adopt any other measure required.

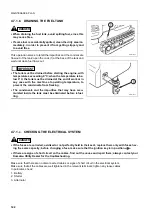

Type of check

Check item

Check before starting

Perdite da giunti, da tubi idraulici o tubi del combustibile

Periodical check (monthly check)

Leakages from joints, hydraulic pipes or fuel pipes. Damaged hy-

draulic or fuel pipes (cracks, wear and tear)

Periodical check (annual check)

Leakages from joints, hydraulic pipes or fuel pipes. Deteriorated,

twisted, damaged hydraulic or fuel pipes (cracks, wear and tear) or

pipes in contact with other parts of the machine

Summary of Contents for PC12R-8

Page 2: ......

Page 12: ...10...

Page 20: ...18...

Page 21: ...SAFETY AND ACCIDENT PREVENTION...

Page 23: ...SAFETY NOISE AND VIBRATION PLATES 21 RWA05440...

Page 27: ...SAFETY NOISE AND VIBRATION PLATES 25 EMERGENCY EXIT LIFTING POINT RWA00190 RWA04920...

Page 55: ...THE MACHINE AND ITS OPERATIONS...

Page 88: ...86...

Page 120: ...118...

Page 121: ...MAINTENANCE...

Page 177: ...TECHNICAL SPECIFICATIONS...

Page 198: ...196...

Page 199: ...AUTHORISED OPTIONAL EQUIPMENT...