201

ARRANGEMENT FOR THE INSTALLATION OF THE DEMOLITION HAMMER (BREAKER)

6.2

ARRANGEMENT FOR THE INSTALLATION OF THE DEMOLI-

TION HAMMER (BREAKER)

6.2.1 DESCRIPTION AND CONTROL

6.2.2 USE OF THE DEMOLITION HAMMER AND RULES TO BE OBSERVED

FOR A CORRECT USE, IT IS NECESSARY TO:

DANGER

•

For the characteristics of the hammer, see “6.1.3 CHARACTERISTICS OF THE OPTIONAL EQUIPMENT”.

•

The demolition hammer is very noisy, therefore always wear headphones when using it.

The machine can be fitted for the application of a demolition

hammer; the operation of the hammer is obtained by means of

an additional distributor controlled by a pedal (1) positioned on

the left side.

The hammer is operated by pressing the pedal (1) with the toe,

since pressurized oil is thus introduced in the delivery circuit (left

side); the oil flow is interrupted and therefore the hammer is

stopped by releasing the pedal (See “3.3.5 pos. 11 OPTIONAL

EQUIPMENT CONTROL”).

RWA06400

1

The choice of the suitable tool is a very important factor to obtain the maximum productivity from the demolition

hammer.

The geometry of the tool must be defined according to the nature of the material to be broken and to the type of

work to be carried out.

The hammer is used to break floors, cement structures, walls, small rocky surfaces, excavations with open sec-

tion, asphalt, etc.

With the application of special tools it can also be used as asphalt-cutter or compactor.

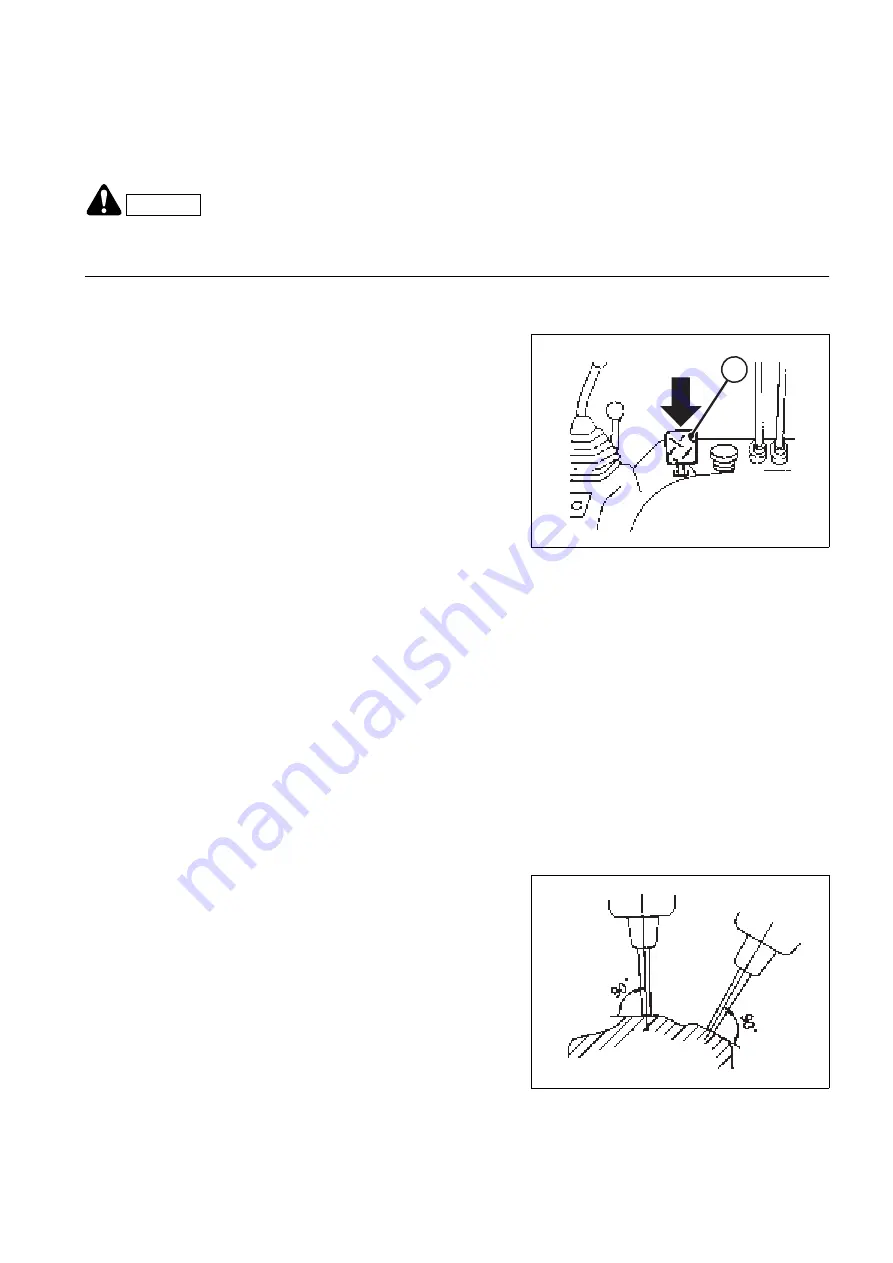

1 - Make sure that the position of the hammer with respect to the

material to be broken is as perpendicular as possible and

that the arm thrust is sufficient, so that all the power of the

hammer can be exploited.

RWA06410

Summary of Contents for PC12R-8

Page 2: ......

Page 12: ...10...

Page 20: ...18...

Page 21: ...SAFETY AND ACCIDENT PREVENTION...

Page 23: ...SAFETY NOISE AND VIBRATION PLATES 21 RWA05440...

Page 27: ...SAFETY NOISE AND VIBRATION PLATES 25 EMERGENCY EXIT LIFTING POINT RWA00190 RWA04920...

Page 55: ...THE MACHINE AND ITS OPERATIONS...

Page 88: ...86...

Page 120: ...118...

Page 121: ...MAINTENANCE...

Page 177: ...TECHNICAL SPECIFICATIONS...

Page 198: ...196...

Page 199: ...AUTHORISED OPTIONAL EQUIPMENT...