MAINTENANCE PROCEDURES

211

4.9.1.b

CHECKING THE BATTERY CHARGE LEVEL

WARNING

q

Check the charge level only with the engine at rest.

q

To prevent gas explosions, do not use naked flames, do not smoke and avoid producing sparks due to

short circuits.

q

The battery electrolyte is dangerous; in case of contact with the eyes or skin, rinse with plenty of water

and consult a doctor without delay. The battery is maintenance-free.

IMPORTANT

q

Make sure that the connection terminals are not oxidized; if necessary, clean them and cover them with

anti-oxidation grease.

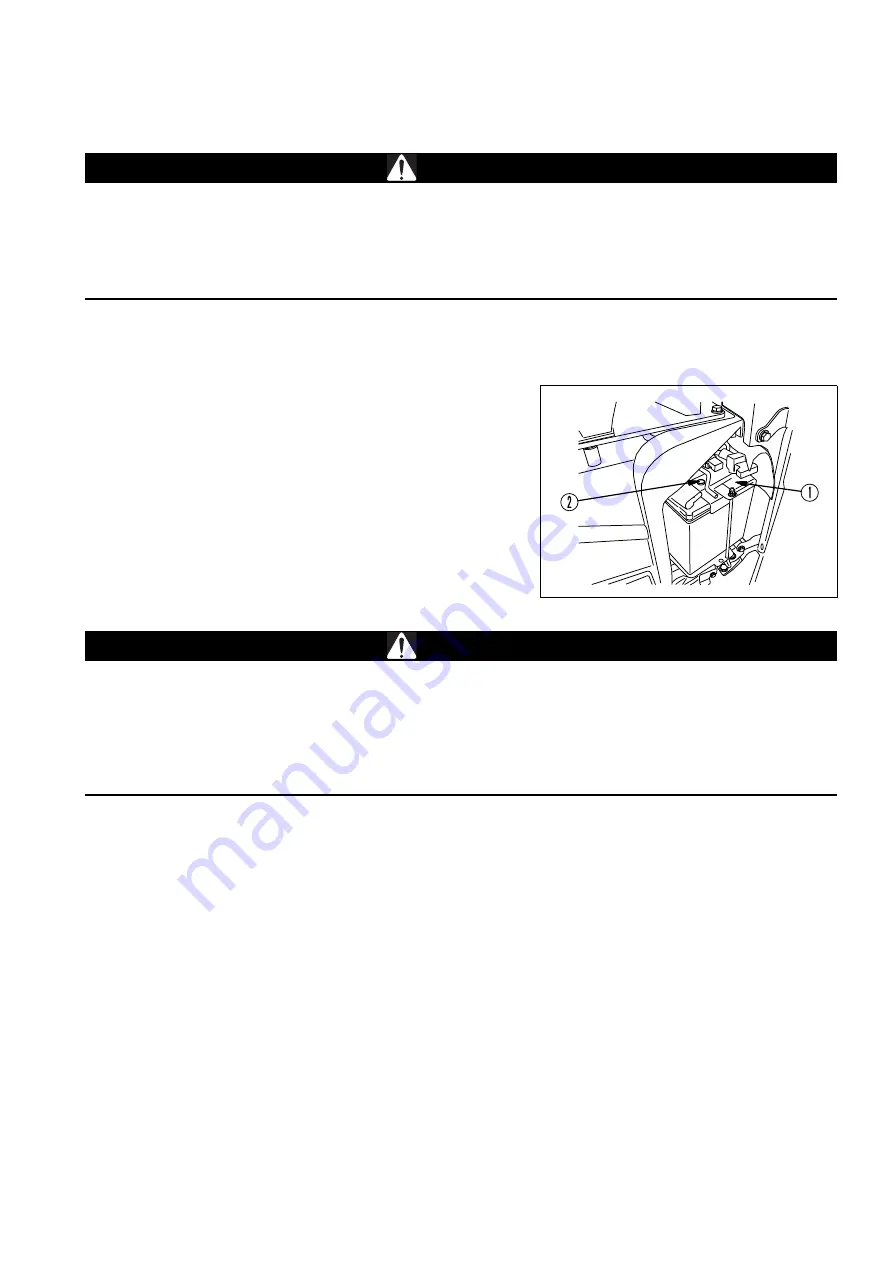

The battery (1) can be reached after removing the battery housing

(see "3.2.8 BATTERY COVER").

A visual indicator (2) signals, with different colours, the battery

charge level according to the table next to the indicator:

-

Green: optimal charge

-

Gray: the battery needs recharging

-

White: the battery must be replaced.

WARNING

q

If a dry battery is used, check that the electrolyte level is approximately 6 mm above the plate edge; if

necessary, top up using distilled water only.

If, on the contrary, the level is low because some fluid has been spilled, add sulphuric acid, after diluting

it to reach the concentration suitable for the ambient temperature (see "3.5.1.3 BATTERY").

q

It is advisable to add distilled water just before starting work, in order to prevent if from freezing.

q

Before putting back the cell caps, make sure that the breather holes are not clogged.

RKA23070

WEAM012405

Summary of Contents for PC16R-3

Page 2: ......

Page 24: ...22 THIS PAGE WAS INTENTIONALLY LEFT EMPTY WEAM012405...

Page 25: ...SAFETY AND ACCIDENT PREVENTION 23 WEAM012405...

Page 79: ...THE MACHINE AND ITS OPERATIONS 77 WEAM012405...

Page 190: ...188 THIS PAGE WAS INTENTIONALLY LEFT EMPTY WEAM012405...

Page 191: ...MAINTENANCE 189 WEAM012405...

Page 244: ...242 THIS PAGE WAS INTENTIONALLY LEFT EMPTY WEAM012405...

Page 245: ...TECHNICAL SPECIFICATIONS 243 WEAM012405...

Page 253: ...AUTHORISED OPTIONAL EQUIPMENT 251 WEAM012405...

Page 286: ...284 WEAM012405...

Page 287: ......

Page 288: ...2017 KOMATSU ITALIA MANUFACTURING S p A All Rights Reserved Printed in Europe 02 2017...