MAINTENANCE PROCEDURES

217

4.9.1.g

CHECKING AND ADJUSTING THE RUBBER TRACK TENSION

The rubber tracks wear out to different degrees, depending on the work conditions and on the characteristics of

the surface on which the machine is working. Therefore, it is necessary to check the track wear and tension fre-

quently, in order to keep the tracks correctly tensioned.

IMPORTANT

q

To carry out the check and the corresponding maintenance operation, stop the machine on firm and lev-

el ground. Check both tracks.

q

In particular, on new machines or after the installation of new tracks, it is advisable to carry out a first

check after 10 hours of operation.

q

Adjusting the track tension frequently until the initial slackening does not occur any longer will prevent

the tracks from coming off due to insufficient tension.

q

If the machine works with loose rubber tracks, they may come off and cause the steel cores to wear out

too early.

CHECK

1.

With the engine idling, move the machine forward of a

distance corresponding to the length of the track on the

ground, then lower the equipment to the ground and stop the

engine.

2.

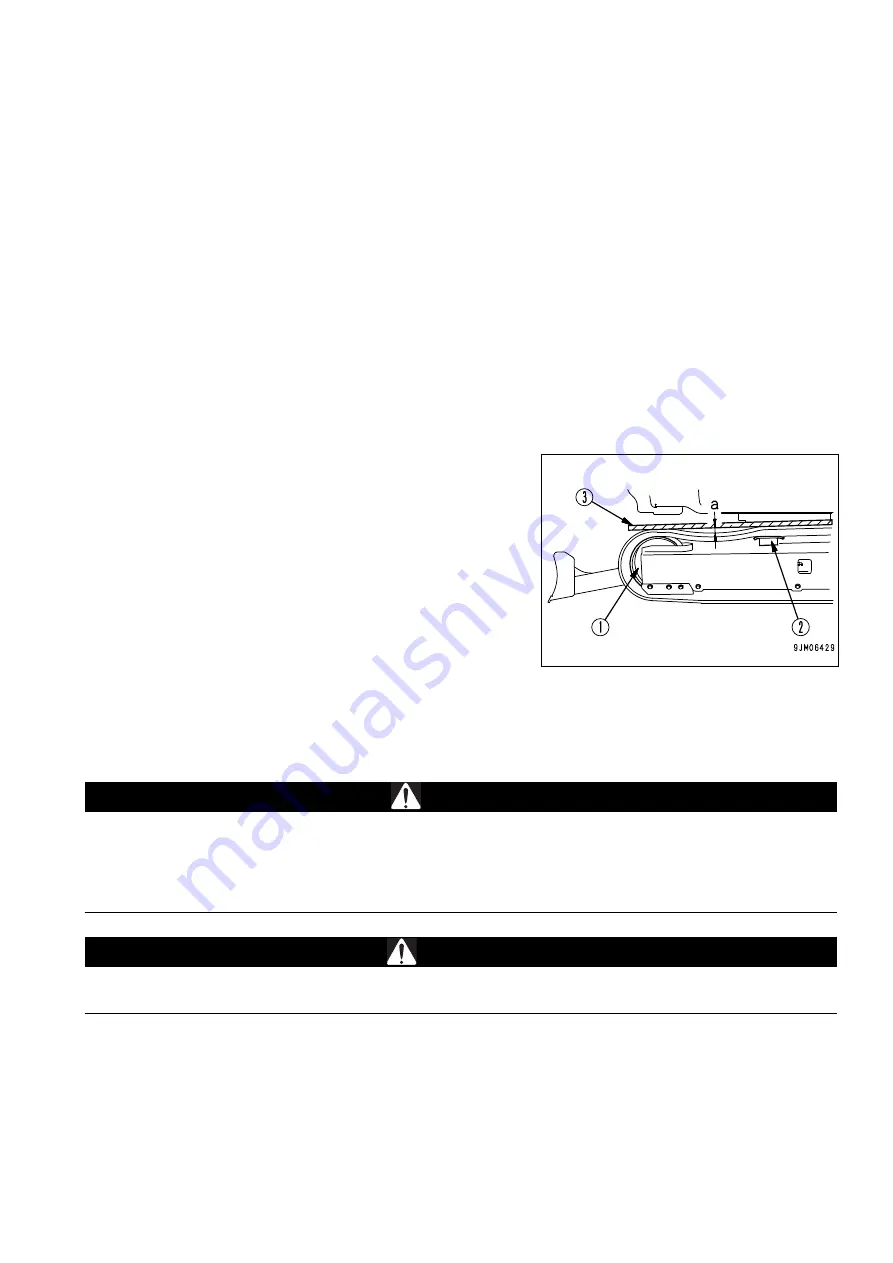

Choose a perfectly flat rod (3) long enough to cover the

distance between the idler roller (1) and the track sliding plate

(2), then position it on the track.

3.

Measure the maximum deflection between the upper surface

of the track and the lower surface of the rod.

Standard deflection

The deflection “a“ should be included between 1 and 3 mm.

If the track tension does not correspond to the standard value, ad-

just it by proceeding as indicated below.

ADJUSTMENT

DANGER

q

The grease contained in the hydraulic cylinder is pressurized. For this reason, do not give the grease

valve (1) more than one turn when loosening it; in fact, if the valve is loosened excessively it may be

pushed out due to the grease pressure and this is very dangerous for the operator..

Do not loose any component apart from the valve (1). If the track tension does not decrease after this op-

eration, contact your Komatsu Distributor.

WARNING

q

If the resistance met when injecting the grease is excessive, move the machine forward and backward

covering a short distance.

WEAM012405

Summary of Contents for PC16R-3

Page 2: ......

Page 24: ...22 THIS PAGE WAS INTENTIONALLY LEFT EMPTY WEAM012405...

Page 25: ...SAFETY AND ACCIDENT PREVENTION 23 WEAM012405...

Page 79: ...THE MACHINE AND ITS OPERATIONS 77 WEAM012405...

Page 190: ...188 THIS PAGE WAS INTENTIONALLY LEFT EMPTY WEAM012405...

Page 191: ...MAINTENANCE 189 WEAM012405...

Page 244: ...242 THIS PAGE WAS INTENTIONALLY LEFT EMPTY WEAM012405...

Page 245: ...TECHNICAL SPECIFICATIONS 243 WEAM012405...

Page 253: ...AUTHORISED OPTIONAL EQUIPMENT 251 WEAM012405...

Page 286: ...284 WEAM012405...

Page 287: ......

Page 288: ...2017 KOMATSU ITALIA MANUFACTURING S p A All Rights Reserved Printed in Europe 02 2017...