MAINTENANCE PROCEDURES

219

4.9.1.h

CHANGING THE RUBBER TRACKS

WARNING

q

This operation must be carried out by two persons. One operator must be seated in the cab and ma-

noeuvre the machine following the signals of the other operator who carries out the change and the ad-

justment.

q

The track must be changed with the frame raised from the ground; be careful not to shift any control le-

ver while the operator is working.

q

During the change do not remove any component apart from the track.

q

If the track tension cannot be reduced by means of the procedure described above, contact your Komat-

su Distributor for the necessary repairs.

IMPORTANT

q

It is possible to switch over from rubber to steel tracks. In any case, it is necessary to remove and adjust

the shock absorber of the idler roller. This operation can be performed only by specialized personnel at

any Komatsu Distributor.

REMOVING THE RUBBER TRACK

DANGER

q

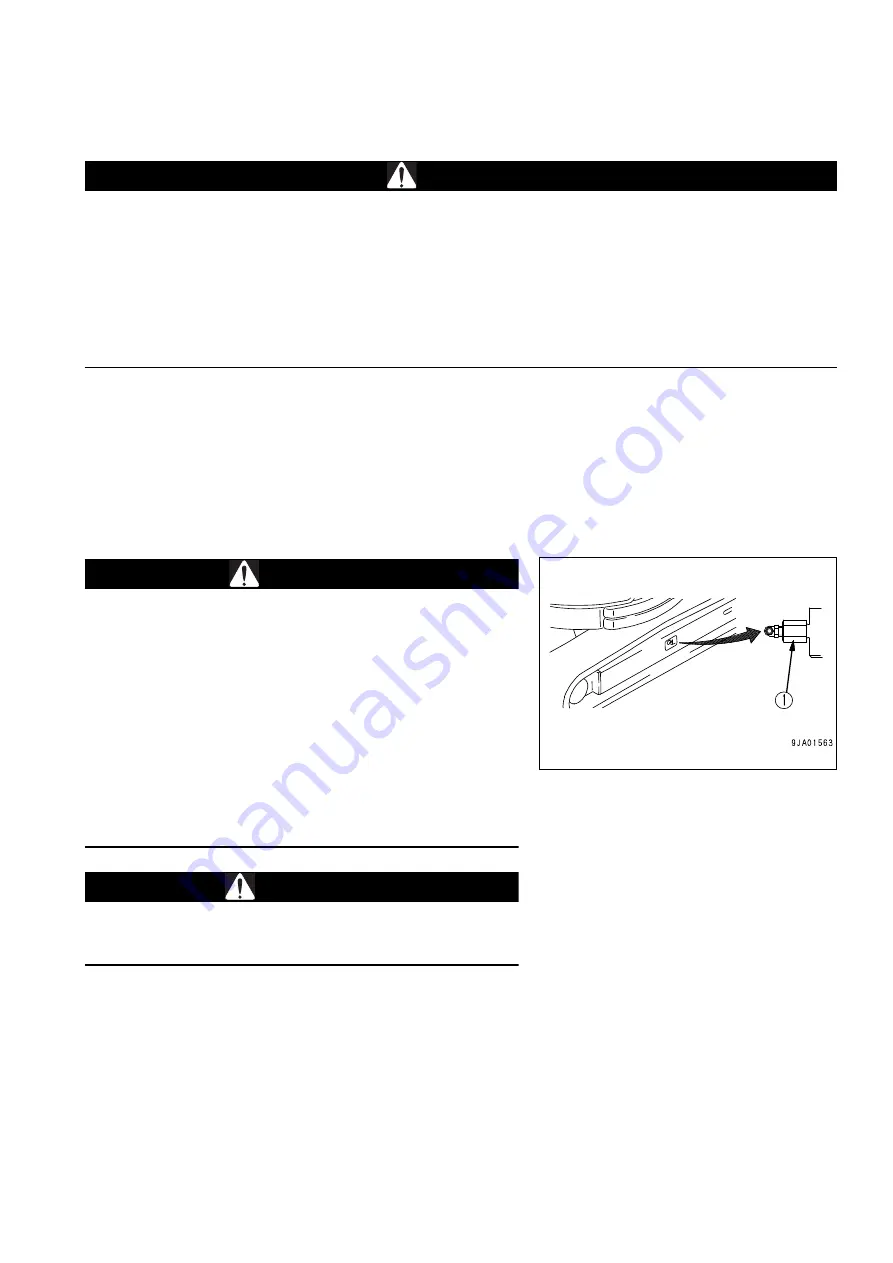

The grease contained in the hydraulic cylinder is pressur-

ized. For this reason, do not give the grease valve (1) more

than one turn when loosening it; in fact, if the valve is loos-

ened excessively it may be pushed out due to the grease

pressure and this is very dangerous for the operator..

Do not loose any component apart from the valve (1). If the

track tension does not decrease after this operation, con-

tact your Komatsu Distributor.

q

It is extremely dangerous to let the grease out following

any procedure different from the one indicated below.

q

When installing or removing the tracks, before turning the

sprocket make sure that the grease contained in the cylin-

der has been removed.

WARNING

q

If the resistance met when injecting the grease is exces-

sive, move the machine forward and backward covering a

short distance.

WEAM012405

Summary of Contents for PC16R-3

Page 2: ......

Page 24: ...22 THIS PAGE WAS INTENTIONALLY LEFT EMPTY WEAM012405...

Page 25: ...SAFETY AND ACCIDENT PREVENTION 23 WEAM012405...

Page 79: ...THE MACHINE AND ITS OPERATIONS 77 WEAM012405...

Page 190: ...188 THIS PAGE WAS INTENTIONALLY LEFT EMPTY WEAM012405...

Page 191: ...MAINTENANCE 189 WEAM012405...

Page 244: ...242 THIS PAGE WAS INTENTIONALLY LEFT EMPTY WEAM012405...

Page 245: ...TECHNICAL SPECIFICATIONS 243 WEAM012405...

Page 253: ...AUTHORISED OPTIONAL EQUIPMENT 251 WEAM012405...

Page 286: ...284 WEAM012405...

Page 287: ......

Page 288: ...2017 KOMATSU ITALIA MANUFACTURING S p A All Rights Reserved Printed in Europe 02 2017...