3.

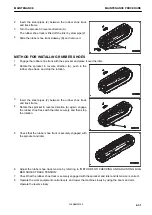

Remove the caps (5) from the top of the battery.

4.

Look into the fluid filler port (6) and check the electrolyte

level.

5.

If the electrolyte does not reach the sleeve (7), immediate-

ly add the purified water (e.g. commercially available re-

plenishment water for a battery) so that the level reaches

the bottom of sleeve (7) (UPPER LEVEL line).

(A) Suitable level

Electrolyte level is up to bottom of sleeve (7), so surface

tension causes electrolyte surface to bulge and poles ap-

pear bent.

(B) Low level

Electrolyte level is not up to bottom of sleeve (7), so poles appear straight and not bent.

REMARK

If the purified water is added to above the lower end of the sleeve (UPPER LEVEL line), remove the fluid by

using a syringe to lower the level to the lower end of the sleeve (UPPER LEVEL line).

Neutralize the removed replenishment water for a battery with baking soda (sodium bicarbonate), then flush

it away with a large amount of water or consult your Komatsu distributor or battery manufacturer.

6.

After adding, tighten the cap (5) securely.

7.

Close the cooling cover (3).

8.

Close the engine rear cover (1).

METHOD FOR CHECKING ELECTROLYTE LEVEL WHEN IT IS POSSIBLE TO

USE INDICATOR TO CHECK ELECTROLYTE LEVEL

If it is possible to use an indicator to check the electrolyte level, follow the instructions given.

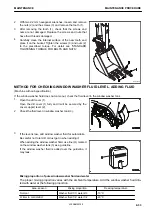

METHOD FOR CLEANING WATER SEPARATOR ELEMENT

k

k

WARNING

Do not bring any open flame close.

• Filter wrench

• Container to catch the fuel

MAINTENANCE PROCEDURE

MAINTENANCE

4-22

WENAM00150

Summary of Contents for PC30MR-5

Page 2: ......

Page 66: ...WENAM00150 ...

Page 69: ... 14 Engine rear cover 15 Cooling cover 16 Battery OPERATION GENERAL VIEW 3 3 WENAM00150 ...

Page 325: ...SPECIFICATIONS 5 1 WENAM00150 ...

Page 363: ...REPLACEMENT PARTS 7 1 WENAM00150 ...

Page 370: ...WENAM00150 ...

Page 379: ......

Page 380: ......