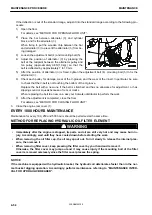

Items to be prepared

• Container to catch drained oil

• Hexagonal wrench

1.

Bring the plug (P) to the lowest position.

2.

Place a container under plug (P) to receive the drained oil.

3.

By using a hexagonal wrench, remove the plugs (P), (G),

and (F) , and drain the oil.

4.

Tighten the plug (P).

5.

Add the refill capacity of oil through plug (F) hole.

6.

When oil begins to overflow from plug (G) hole, install the

plugs (G) and (F).

METHOD FOR CHECKING AND ADJUSTING ENGINE VALVE CLEARANCE

Special tools are necessary for inspection and maintenance. Ask your Komatsu distributor to perform this work.

EVERY 1500 HOURS MAINTENANCE

Maintenance for every 100, 250 and 500 hours should be performed at the same time.

METHOD FOR CHECKING AND CLEANING FUEL INJECTION SYSTEM

If the fuel injection system does not operate normally, engine performance cannot be obtained thoroughly. It is

necessary to check and clean the fuel injection system. Special tools are needed for inspection and mainte-

nance, so ask your Komatsu distributor to perform this work.

METHOD FOR CHECKING CRANKCASE BREATHER

If the crankcase breather does not work normally, the engine does not conform to the exhaust gas regulations

under usage period. It is necessary to check the diaphragm for damage and the spring for breakage. Special

tools are needed for inspection and maintenance, so ask your Komatsu distributor to perform this work.

EVERY 2000 HOURS MAINTENANCE

Maintenance for every 100, 250, 500 and 1000 hours should be performed at the same time.

MAINTENANCE

MAINTENANCE PROCEDURE

4-57

WENAM00150

Summary of Contents for PC30MR-5

Page 2: ......

Page 66: ...WENAM00150 ...

Page 69: ... 14 Engine rear cover 15 Cooling cover 16 Battery OPERATION GENERAL VIEW 3 3 WENAM00150 ...

Page 325: ...SPECIFICATIONS 5 1 WENAM00150 ...

Page 363: ...REPLACEMENT PARTS 7 1 WENAM00150 ...

Page 370: ...WENAM00150 ...

Page 379: ......

Page 380: ......