Set the machine in the posture shown in the figure.

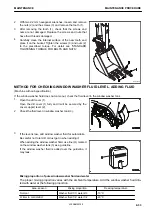

1) Start the engine and run it at low idle.

2) Set the lock lever to FREE position (F).

3) Operate the work equipment control lever to swing the up-

per structure to make it right angle with the undercarriage.

Bring the work equipment to the side of the track.

4) Operate the work equipment control levers, and push up

the machine slowly by using the boom and arm until the

track is raised from the ground.

Operate the levers slowly.

5) Set the lock lever to LOCK position (L).

6) Stop the engine.

METHOD FOR REMOVING RUBBER SHOES

k

k

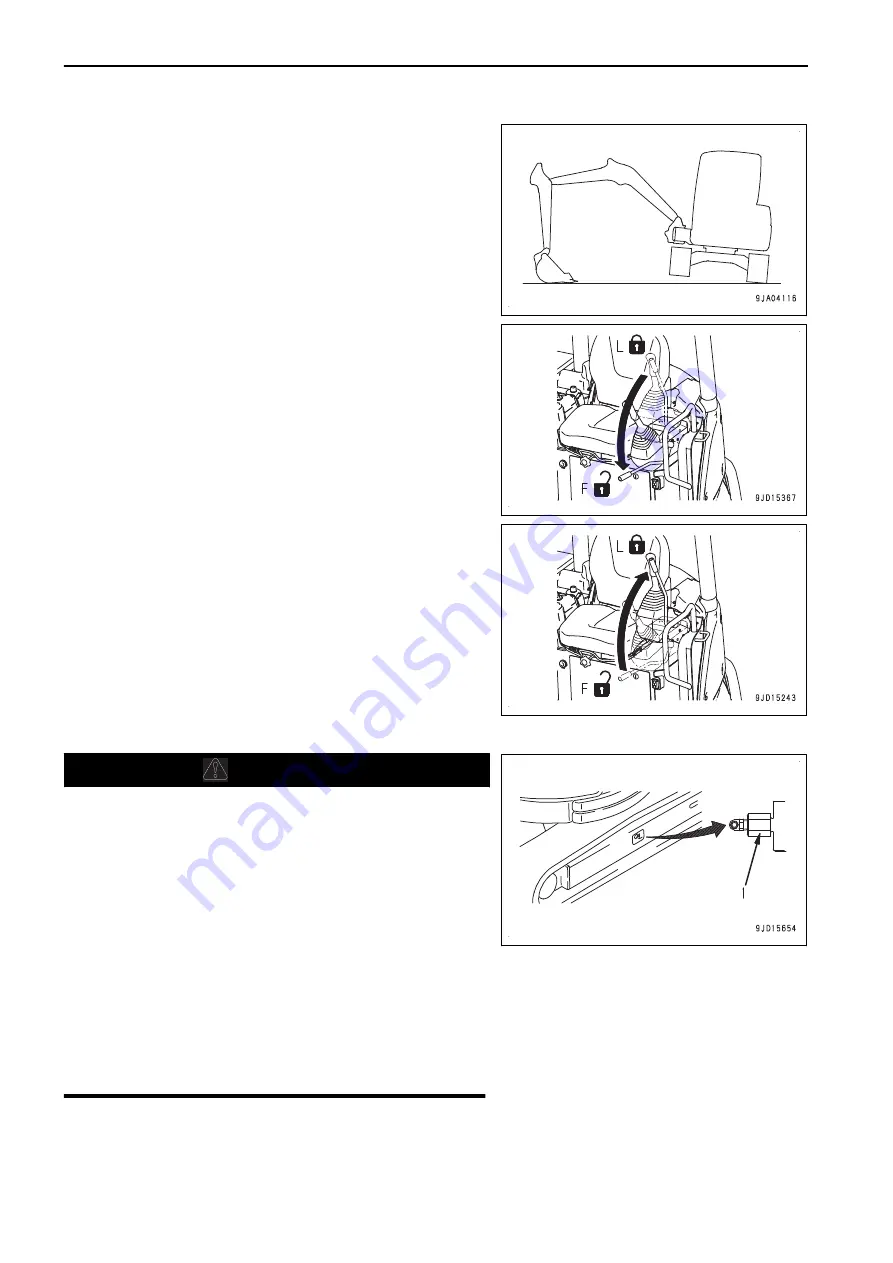

WARNING

• Grease is pumped into the track tension adjustment

system under high pressure.

If the adjustment is performed with the procedure oth-

er than following, grease drain plug (1) may fly out and

cause serious injury or death.

If the rubber shoe track is not loosened, ask your Ko-

matsu distributor for repair.

• Do not loosen grease drain plug (1) more than 1 turn.

• Do not loosen any part other than grease drain plug

(1).

• Do not put your face, hands, feet, or any other part of

your body close to grease drain plug (1).

• Before removing the rubber shoe track, check that the

internal grease is fully discharged, and then turn the

sprocket.

1.

Loosen grease drain plug (1) gradually to release the grease.

MAINTENANCE PROCEDURE

MAINTENANCE

4-30

WENAM00150

Summary of Contents for PC30MR-5

Page 2: ......

Page 66: ...WENAM00150 ...

Page 69: ... 14 Engine rear cover 15 Cooling cover 16 Battery OPERATION GENERAL VIEW 3 3 WENAM00150 ...

Page 325: ...SPECIFICATIONS 5 1 WENAM00150 ...

Page 363: ...REPLACEMENT PARTS 7 1 WENAM00150 ...

Page 370: ...WENAM00150 ...

Page 379: ......

Page 380: ......