MAINTENANCE

MAINTENANCE SCHEDULE

4-19

MAINTENANCE INTERVAL FOR HYDRAULIC BREAKER

4

For machine equipped with a hydraulic breaker, the hydraulic oil deteriorates faster than for normal bucket dig-

ging operations, so set the maintenance intervals as follows.

q

Replace hydraulic filter element

On a new machine, replace the element after the first 100

to 150 hours, then carry out further replacement of the ele-

ment according to the table on the right.

q

Change oil in hydraulic tank

Change the oil according to the table on the right.

q

Replacing additional filter element for breaker (if

equipped)

Use a guideline of 250 hours for use of the breaker (operat-

ing ratio for the breaker: 50 % or more), and replace the

element according to the table on the right.

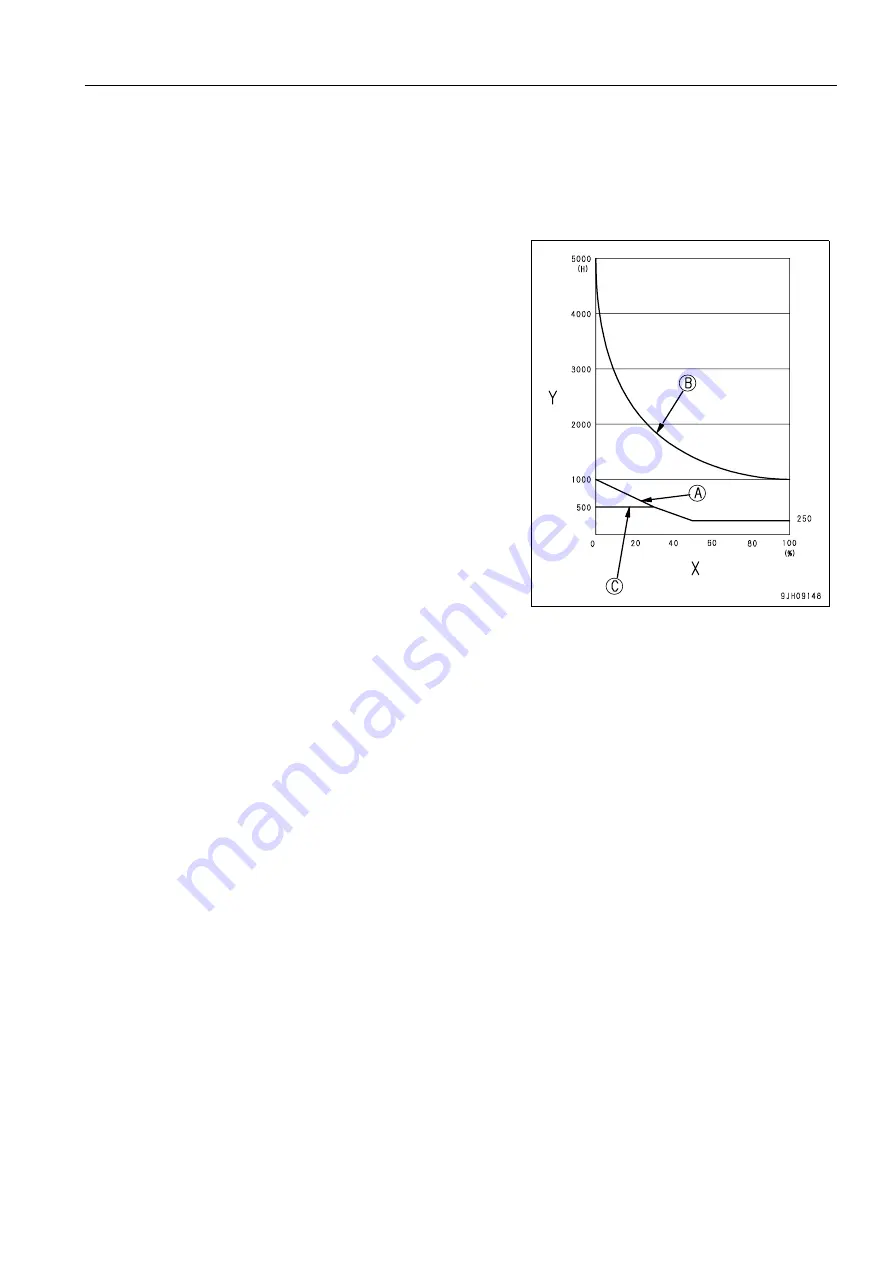

X : Breaker operating ratio (%)

Y : Replacement interval (H)

(A): Hydraulic filter element

(B): Hydraulic oil

(C): Additional filter element

REMARK

Breaker operating ratio 100% means that only the breaker is

used

Breaker operating ratio 0% means that the breaker is not used

Summary of Contents for PC450-8

Page 2: ......

Page 3: ...FOREWORD 11 ...

Page 66: ...SAFETY MAINTENANCE INFORMATION SAFETY 2 42 ...

Page 351: ...SPECIFICATIONS 15 ...

Page 355: ...SPECIFICATIONS SPECIFICATIONS 5 5 6 7m Boom PC450 8 ...

Page 356: ...SPECIFICATIONS SPECIFICATIONS 5 6 6 7m Boom PC450LC 8 ...

Page 357: ...SPECIFICATIONS SPECIFICATIONS 5 7 6 7m Boom PC450LCHD 8 ...

Page 359: ...SPECIFICATIONS SPECIFICATIONS 5 9 7 0m Boom PC450 8 ...

Page 360: ...SPECIFICATIONS SPECIFICATIONS 5 10 7 0m Boom PC450LC 8 ...

Page 410: ...SUPER LONG FRONT BOOM AND ARM ATTACHMENTS ANDD OPTIONS 6 50 ...

Page 436: ...OPERATION HIGH REACH DEMOLITION EQUIPMENT 27M 7 26 3 Extend arm cylinder Arm cylinder ...

Page 469: ...INDEX 18 ...

Page 470: ...INDEX 8 2 ...

Page 473: ...COLOPHON 18 ...